A method for strengthening steel pipe joints with plates

It is a technology of ring joint plate and joint, which is applied in the direction of construction and building structure. It can solve the problems of main pipe incision or weld damage, complex construction, and affecting the appearance of the structure, so as to improve the seismic performance and ductility, increase the bearing capacity, Effect of Good Seismic Ductility Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

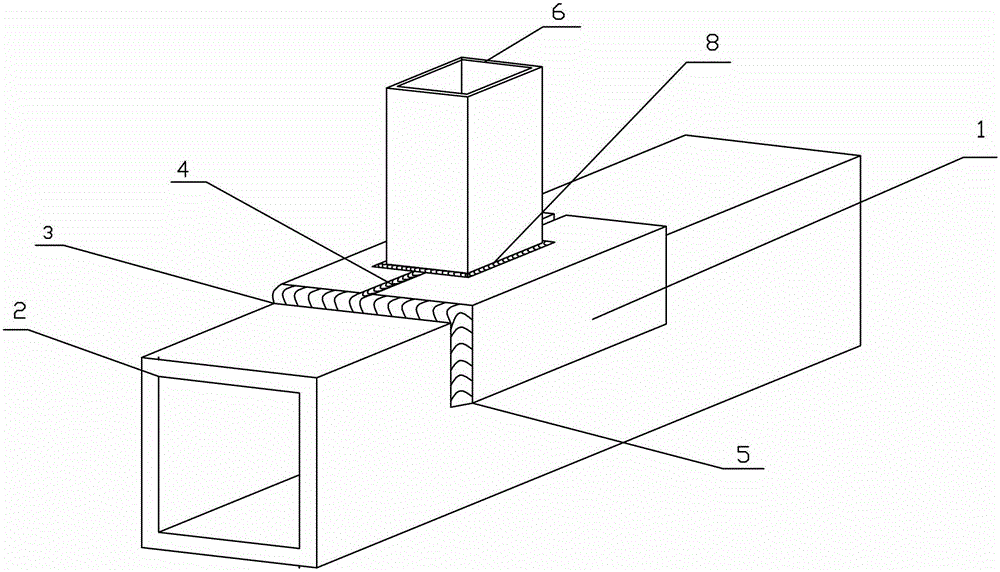

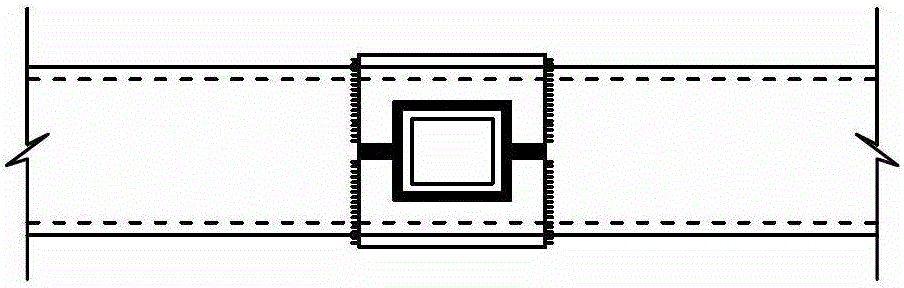

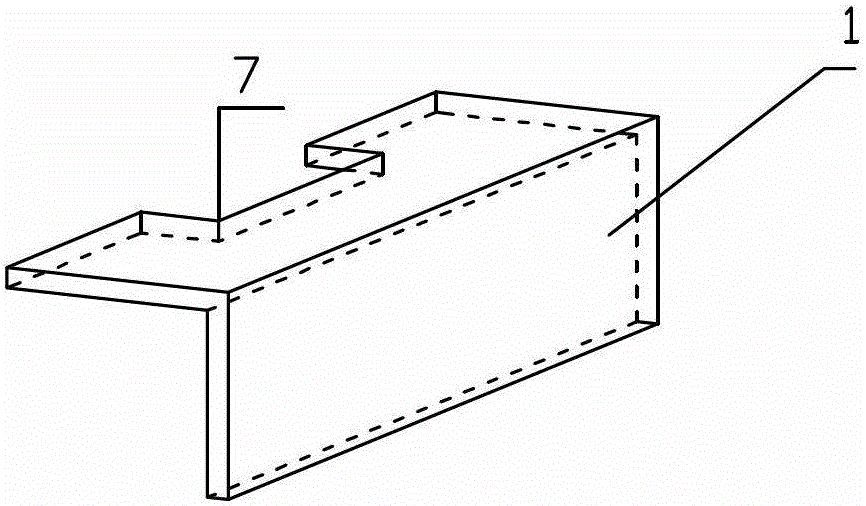

[0016] As shown in the figure: a method for strengthening the ring mouth of a steel pipe node, the ring mouth of the steel pipe node includes the main pipe 2 and the branch pipe 6 of the reinforced node, and the ring mouth is bonded between the main pipe and the branch pipe of the reinforced node by welding Lamination plate 1, an orifice 7 with the same shape as the branch pipe 6 is opened on one side of the ring mouth lamination plate, which is connected by a surrounding weld 8; the ring mouth lamination plate is symmetrically arranged on both sides of the reinforced node, surrounding the branch pipe 6, and will be strengthened The node supervisor is surrounded by 2 halves.

[0017] The main pipe of the strengthened node is connected with the ring joint plate through the side weld 3 and the front surface weld seam 5 ;

[0018] The reinforced node main pipe 2 is a square or rectangular steel pipe; the branch pipe 6 is a rectangular or round steel pipe.

[0019] When the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com