Novel steel pipe column and shaped steel beam assembling method

An assembly method and a technology of steel pipe columns, which are applied in the direction of construction and building construction, can solve the problems of inconvenient assembly, low load action, and high cost, and achieve the effects of increasing bearing capacity, good seismic ductility, and improving seismic performance and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

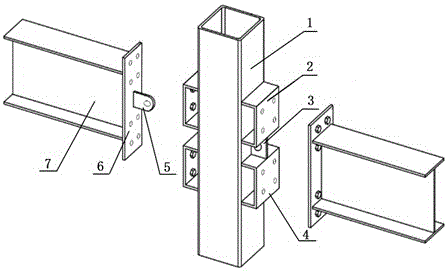

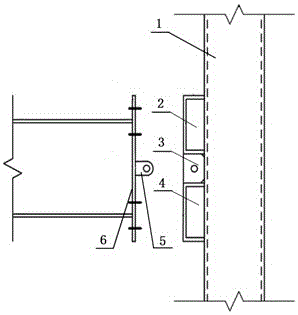

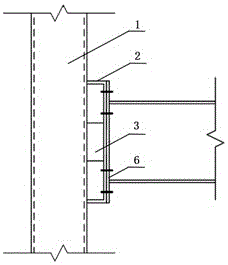

[0014] A new assembly method of a steel pipe column and a shaped steel beam, comprising: a steel pipe column 1, an upper flange U-shaped steel or channel steel 2, a shear web 3, a lower flange U-shaped steel or a channel steel 4, and beam end lugs 5 , beam end plate 6, open-shaped steel beam 7; a new assembly method of a steel pipe column and a steel beam, on both sides of a steel pipe column 1 with a closed section, a plurality of bolts are welded vertically to the symmetrical axis respectively The U-shaped steel or channel steel 2 of the upper flange of the hole is welded with the U-shaped steel or channel steel 4 of the lower flange with multiple bolt holes at its lower part, and the U-shaped steel or channel steel 2 of the upper flange and the lower flange The shear web 3 with bolt holes is welded in the gap between the U-shaped steel or the channel-shaped steel 4; the open-shaped steel beam 7 is I-shaped, H-shaped, and groove-shaped, and a beam end plate 6 is welded at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com