A high-impact high-pressure water pump shell material based on long glass fiber modified polypropylene and its preparation method

A high-pressure water pump and shell material technology, applied in the field of new materials, can solve the problems of high price, heavy metal pollution in water, heavy metal pollution, etc., and achieve the effect of solving weather resistance problems and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

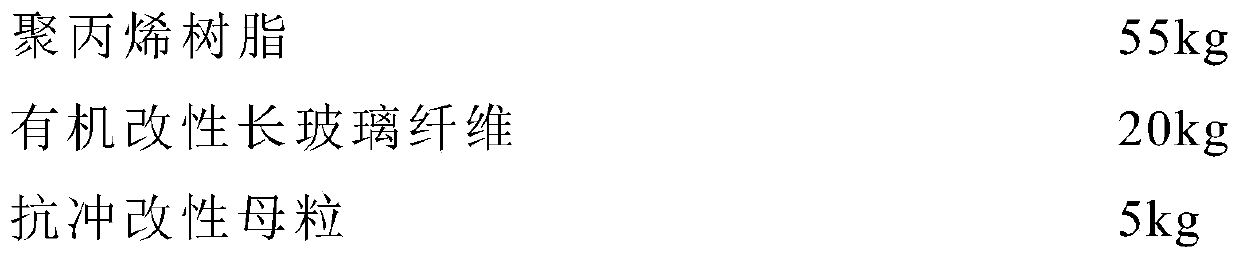

[0026] A high-pressure water pump housing material based on long glass fiber modified polypropylene, which consists of the following raw materials in parts by weight:

[0027]

[0028]

[0029] The organically modified long glass fiber is an alkali-free glass fiber treated with a sizing agent, and its aspect ratio is 200-350. The preparation method of organic modified long glass fiber comprises the following steps:

[0030] Step 1: Add 5% rutile nano-titanium dioxide and 2% liquid high molecular weight phenolic antioxidant IRGANOX L13 to the oxidized polyethylene wax emulsion with a solid content of 35%, and stir until fully dispersed to obtain a wetting agent liquid;

[0031] Step 2, putting the sizing liquid and the long glass fibers described in step 1 into a high-speed mixer for mixing, the mixing time is 1 hour, and the mass ratio of the sizing liquid to the long glass fibers is 2:10;

[0032] Step 3, drying the mixture obtained in Step 2 at 75° C. for 4 hours to o...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, except that a high-pressure water pump housing material based on long glass fiber modified polypropylene is composed of the following raw materials in parts by weight:

[0043]

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, except that a high-pressure water pump housing material based on long glass fiber modified polypropylene is composed of the following raw materials in parts by weight:

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com