A pe‑rt pipe material

A PE-RT and modification technology, applied in the field of plastic pipes, can solve the problems of inflection points in the hydrostatic curve, unsuitable pipes, insufficient tensile strength, etc. Excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

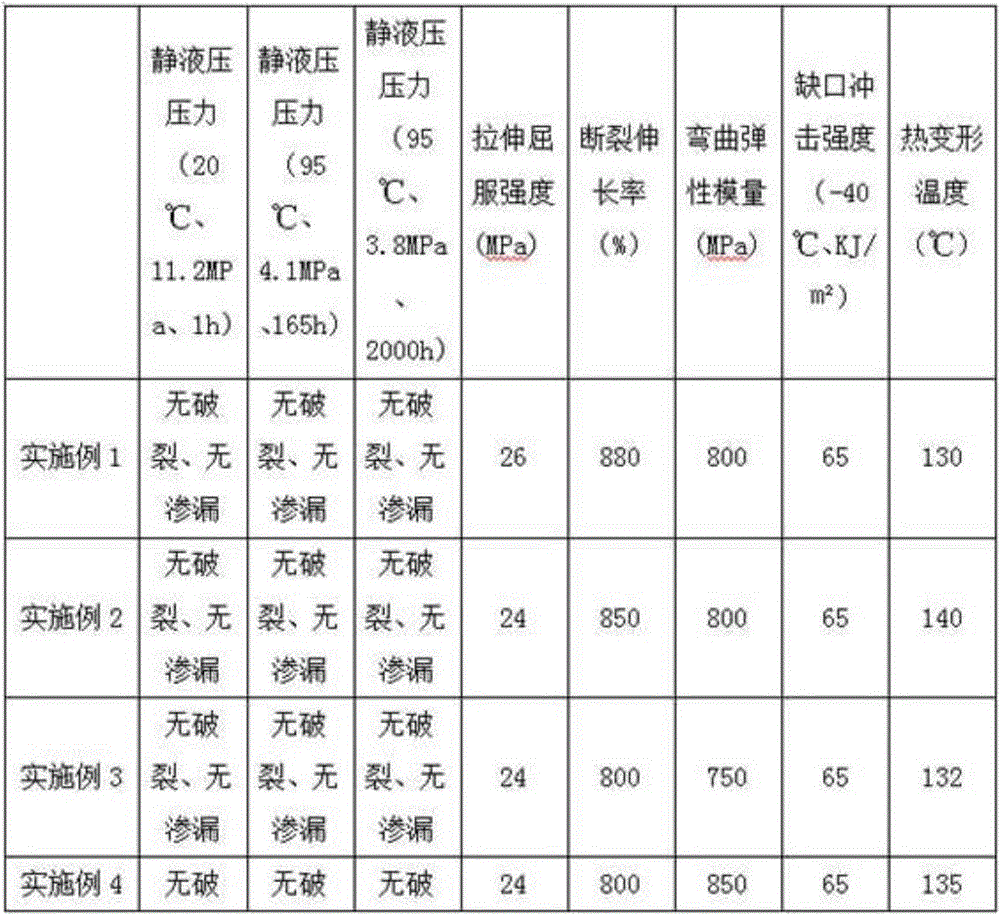

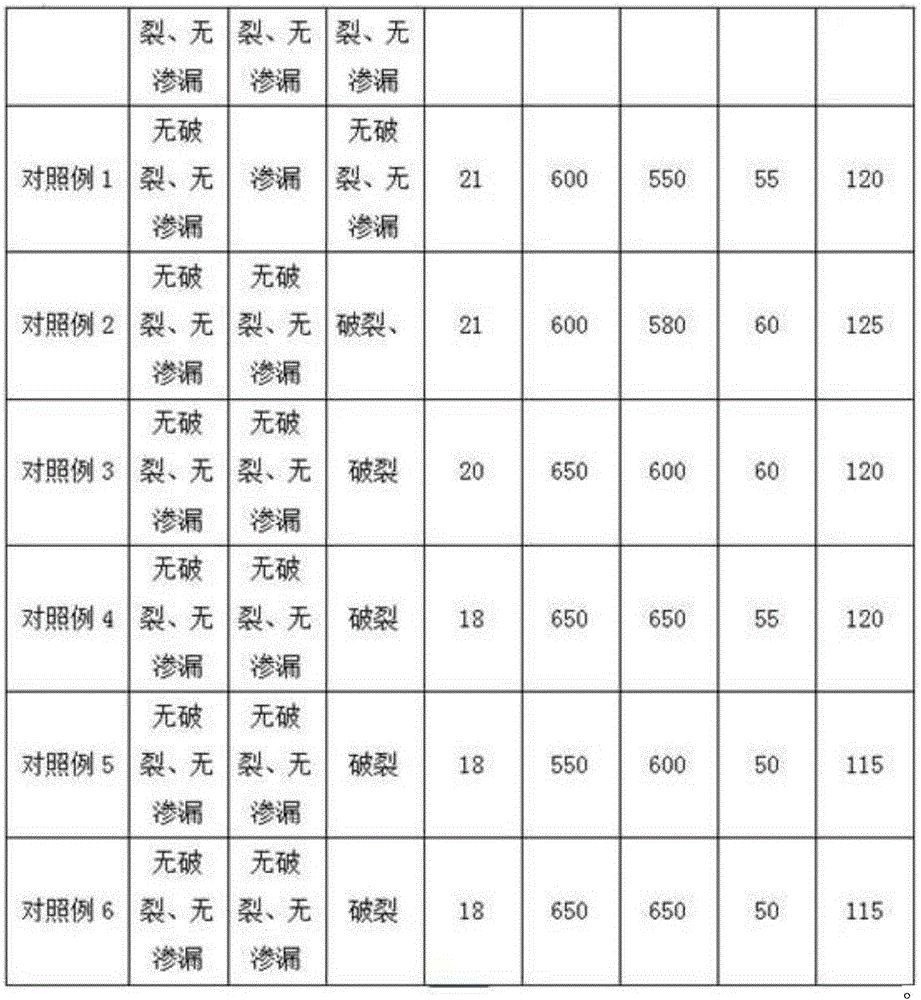

Examples

Embodiment 1

[0025] A kind of PE-RT pipe material, described PE-RT pipe material is made up of following raw material by weight part: heat-resistant polyethylene PE-RT 90 parts, CHA-3 nucleating agent (aryl carboxylic acid metal soap) 0.2 part , 3 parts of styrene-acrylate emulsion, 8 parts of wood fiber, 0.2 part of vinyl tris (β-methoxyethoxy) silane.

[0026] The above PE-RT pipe material is prepared according to the following preparation method: PE-RT pipe material:

[0027] (1) wood fiber is dehumidified and dried, and wood fiber is modified by styrene-acrylate emulsion;

[0028] (2) Put the modified wood fiber and vinyl tris(β-methoxyethoxy)silane into a high-speed thermomixer, mix and stir for 5min, then put it into a cold mixer and cool to normal temperature to obtain a modified Material A;

[0029] (3) Put heat-resistant polyethylene PE-RT and aryl carboxylate polyolefin nucleating agent into a high-speed mixer, heat up to 80°C, mix and stir for 5 minutes, then put into a cold m...

Embodiment 2

[0032] A PE-RT pipe material, said PE-RT pipe material is composed of the following raw materials in parts by weight: 95 parts of heat-resistant polyethylene PE-RT, 0.5 parts of hydroxyaluminum p-tert-butylbenzoate (A1-PTB-BA) 8 parts, 8 parts of styrene-acrylate emulsion, 15 parts of wood fiber, 0.5 parts of vinyl tris (β-methoxyethoxy) silane.

[0033] The method for preparing the PE-RT pipe from the PE-RT pipe material of this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0035] A PE-RT pipe material, the PE-RT pipe material is composed of the following raw materials in parts by weight: 92 parts of heat-resistant polyethylene PE-RT, 0.3 parts of Ca-G nucleating agent, 5 parts of styrene-acrylate emulsion 10 parts, 10 parts of wood fiber, 0.3 parts of vinyl tris (β-methoxyethoxy) silane.

[0036] The method for preparing the PE-RT pipe from the PE-RT pipe material of this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com