A high temperature resistant, high pressure resistant polyethylene composition

A heat-resistant polyethylene and high-pressure technology, applied in the high-pressure polyethylene composition and high-temperature field, can solve the problem of increasing the complexity and production cost of the pipe production process, low pressure resistance and physical and mechanical properties, and high pressure resistance. Low grade and other problems, to achieve the effect of saving raw materials for pipe production, good high temperature oxidation resistance, and improving heat resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

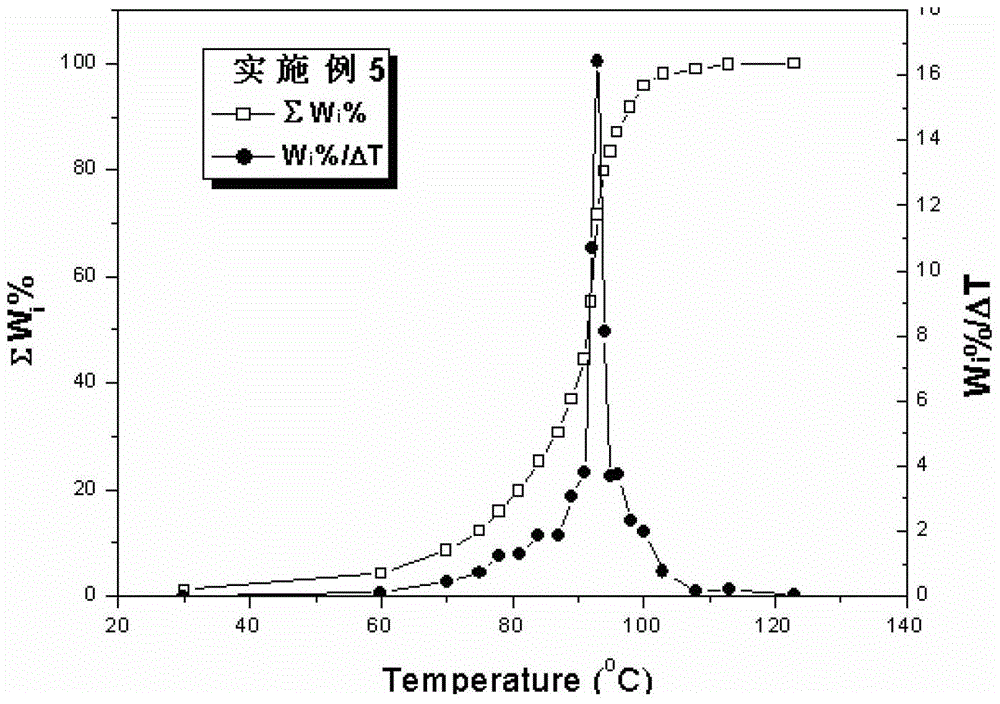

Image

Examples

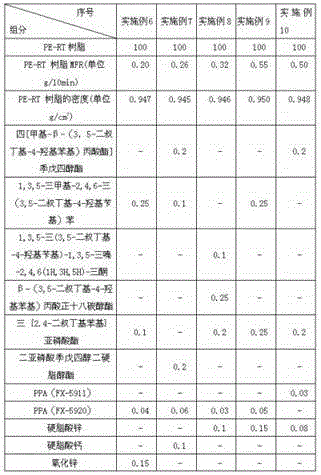

Embodiment 1~5

[0026] The preparation method of embodiment 1~5, carry out as follows:

[0027] a) Put the heat-resistant polyethylene resin, antioxidant, acid absorbing agent, and processing aid into a high-speed mixer to stir and mix, the stirring speed is 1300 rpm, the stirring time is 12min, and the stirring temperature is 38°C;

[0028] b) Add the homogeneously mixed materials into a twin-screw extruder for melting, plasticizing, extruding, and granulating. The length-to-diameter ratio of the screw is 36, and the screw combination used has 6 shear blocks, including 3 reverse shear blocks, and the processing temperature is 230°C.

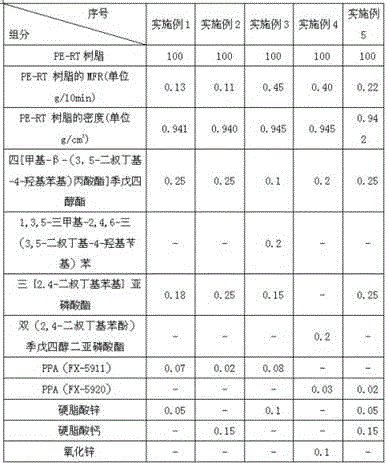

Embodiment 6~10

[0031]The preparation method of embodiment 6~10, carry out as follows:

[0032] a) Put the heat-resistant polyethylene resin, antioxidant, acid absorbing agent, and processing aid into a high-speed mixer to stir and mix, the stirring speed is 1600 rpm, the stirring time is 13min, and the stirring temperature is 40°C;

[0033] b) Add the homogeneously mixed materials into a twin-screw extruder for melting, plasticizing, extruding, and granulating. The length-to-diameter ratio of the screw is 34, and the screw combination used has 5 shear blocks, including 2 reverse shear blocks, and the processing temperature is 225°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com