Thermoplastic composite material for hollow building templates and manufacture method thereof and application thereof

A technology of composite materials and building templates, which is applied in building construction, on-site preparation of building components, construction, etc., can solve the problems of large plate extrusion and easy warping of products, and achieve light weight, long-term weather resistance, Guaranteed long-term application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0037] (1) Weigh the material according to the components and proportioning ratio provided in Table 1;

[0038] (2) Mix evenly in a high-speed mixer, put it in a high-speed mixer and mix for 3 minutes

[0039] (3) The composition is obtained after extrusion in a twin-screw extruder. The barrel temperature of the extruder is 180-230°C. The extrusion temperature of each stage is set at 200°C-205°C-210°C-215°C-215°C-215°C-225°C.

[0040] (4) Extruded hollow building formwork, through 9 processes of thermoplastic composite material melting, extrusion molding products, vacuum cooling and shaping, primary traction, heating stress relief, secondary traction, cutting, stacking, packaging, etc. requested product.

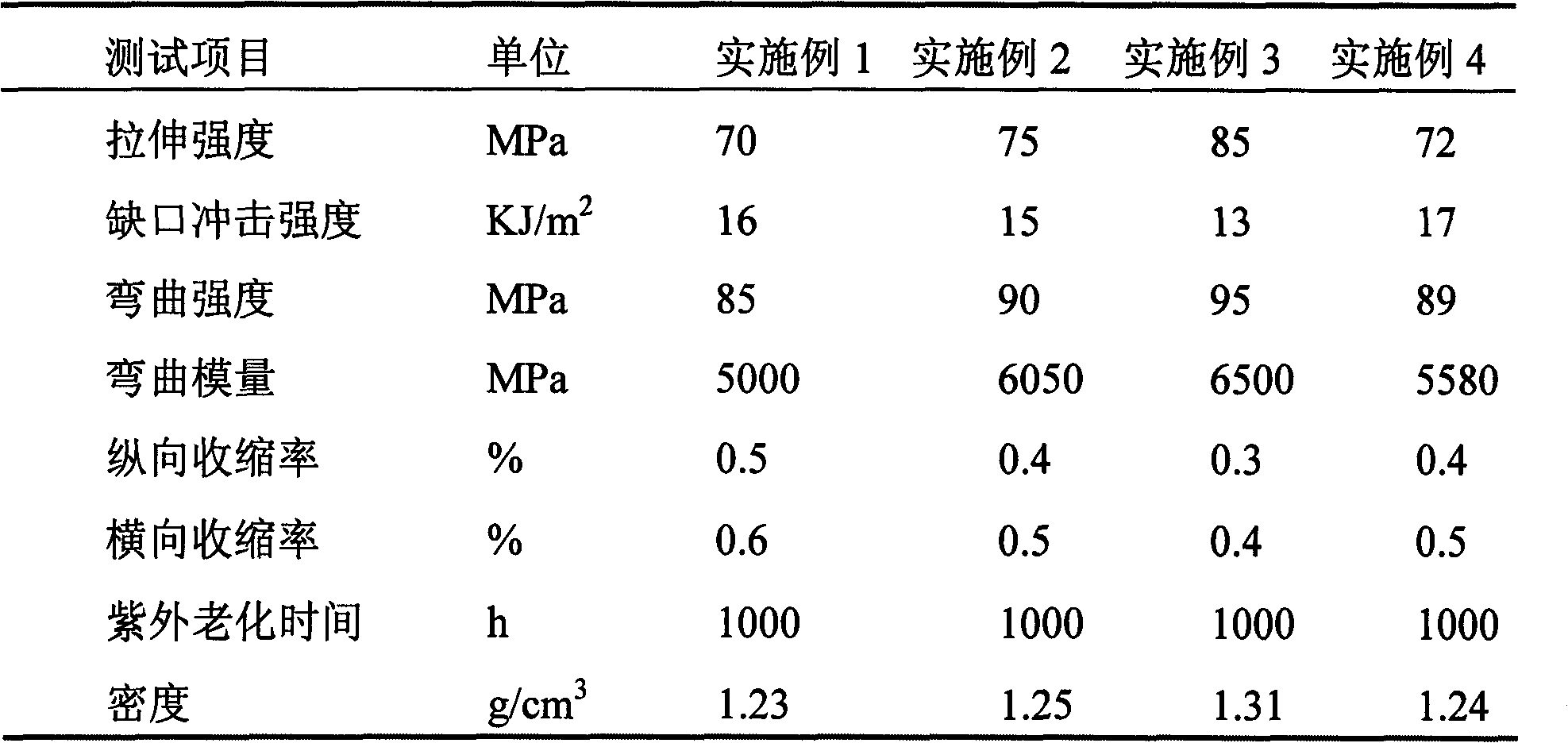

[0041] The material properties of the product are tested according to GB standards. The test results are shown in Table 2.

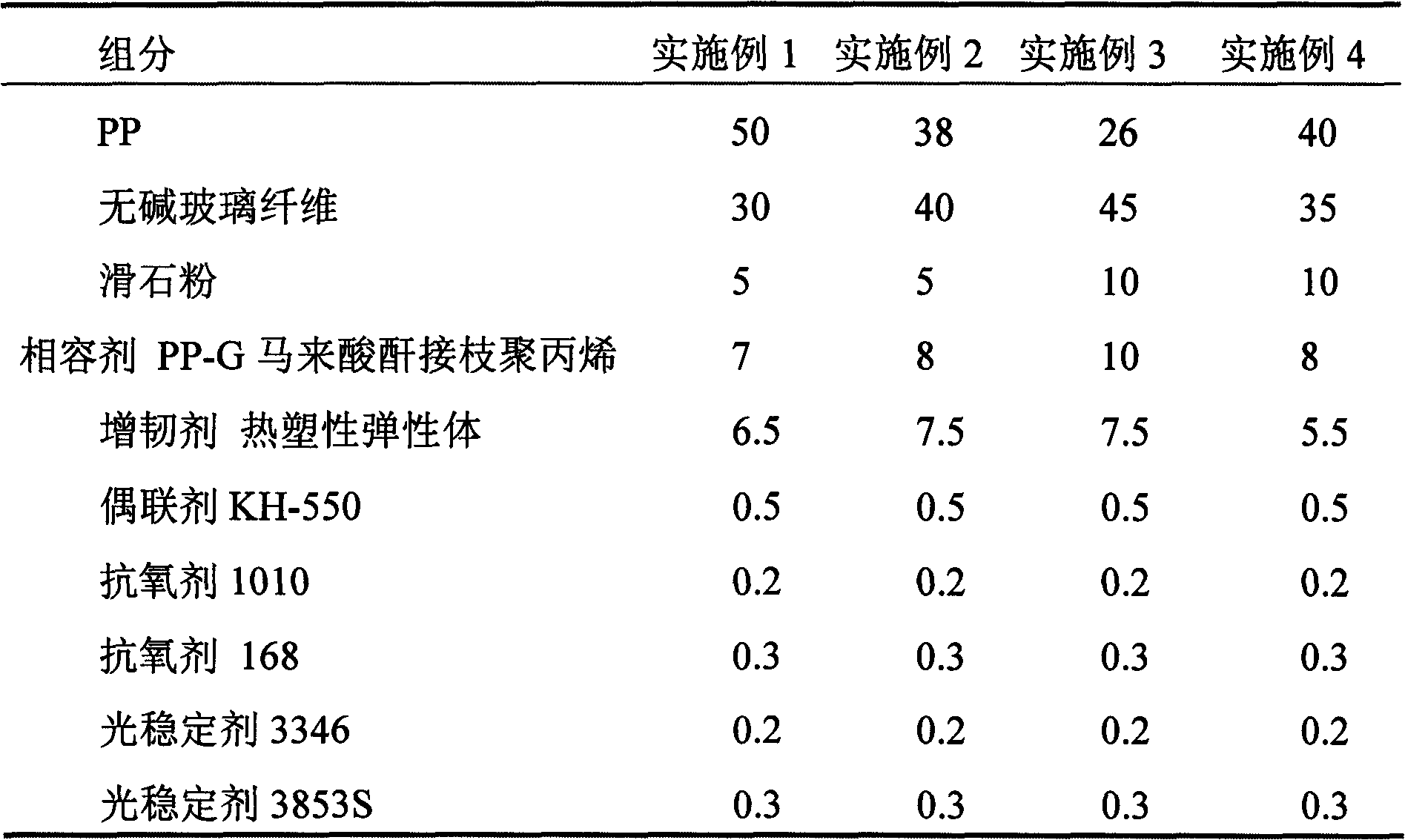

[0042] Components and proportioning of table 1 embodiment 1-4 (following examples are all by weight percentage)

[0043]

[0044] The perform...

Embodiment 5

[0047] (1) Weigh 20 copolymerized polypropylenes with a melt index of 2 to 5 g / 10min, 50 alkali-free long glass fibers, 10 inorganic filler wollastonite, 9.5 toughening agent nitrile rubber, and compatibilizer maleic anhydride in parts by weight Grafted polypropylene 10, 0.1 coupling agent KH550, 0.05 antioxidant 1010, 0.05 antioxidant 618, light stabilizer 3346 and light stabilizer 3853S mixed in a weight ratio of 3:4 light stabilizer 0.4;

[0048] (2) Mix evenly in a high-speed mixer, put into a high-speed mixer and mix for 5 minutes;

[0049] (3) The composition is obtained after extrusion in a twin-screw extruder. The barrel temperature of the extruder is 180-230°C. The extrusion temperature of each section is set at 200°C-205°C-210°C-215°C-215°C-215°C-225°C;

[0050] (4) Extruded hollow building formwork, through 9 processes of thermoplastic composite material melting, extrusion molding products, vacuum cooling and shaping, primary traction, heating stress relief, secon...

Embodiment 6

[0052] (1) Weigh 25 homopolypropylenes with a melt index of 2 to 5 g / 10min, 25 copolymerized polypropylenes with a melt index of 1 to 3 g / 10min, 30 alkali-free chopped glass fibers, 5 wollastonite inorganic fillers, and Toughener ethylene-acrylate copolymer 7, compatibilizer maleic anhydride grafted polypropylene 6.5, coupling agent 0.5, 0.2 antioxidant 1010, 0.3 antioxidant 168, light stabilizer 3346 and light stabilizer 3853S by weight 3:4 mixed light stabilizer 0.5;

[0053] (2) Mix evenly in a high-speed mixer, put into a high-speed mixer and mix for 5 minutes;

[0054] (3) The composition is obtained after extrusion in a twin-screw extruder. The barrel temperature of the extruder is 180-230°C. The extrusion temperature of each section is set at 200°C-205°C-210°C-215°C-215°C-215°C-225°C;

[0055] (4) Extruded hollow building formwork, through 9 processes of thermoplastic composite material melting, extrusion molding products, vacuum cooling and shaping, primary traction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com