Extruded expanded polypropylene beads and preparation method thereof

A technology for extruding foam and polypropylene, applied in the field of polymer foam material production, can solve the problems of inapplicability, complex production process, difficult to achieve, etc., and achieve the effects of high mechanical strength, thermal deformation temperature, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

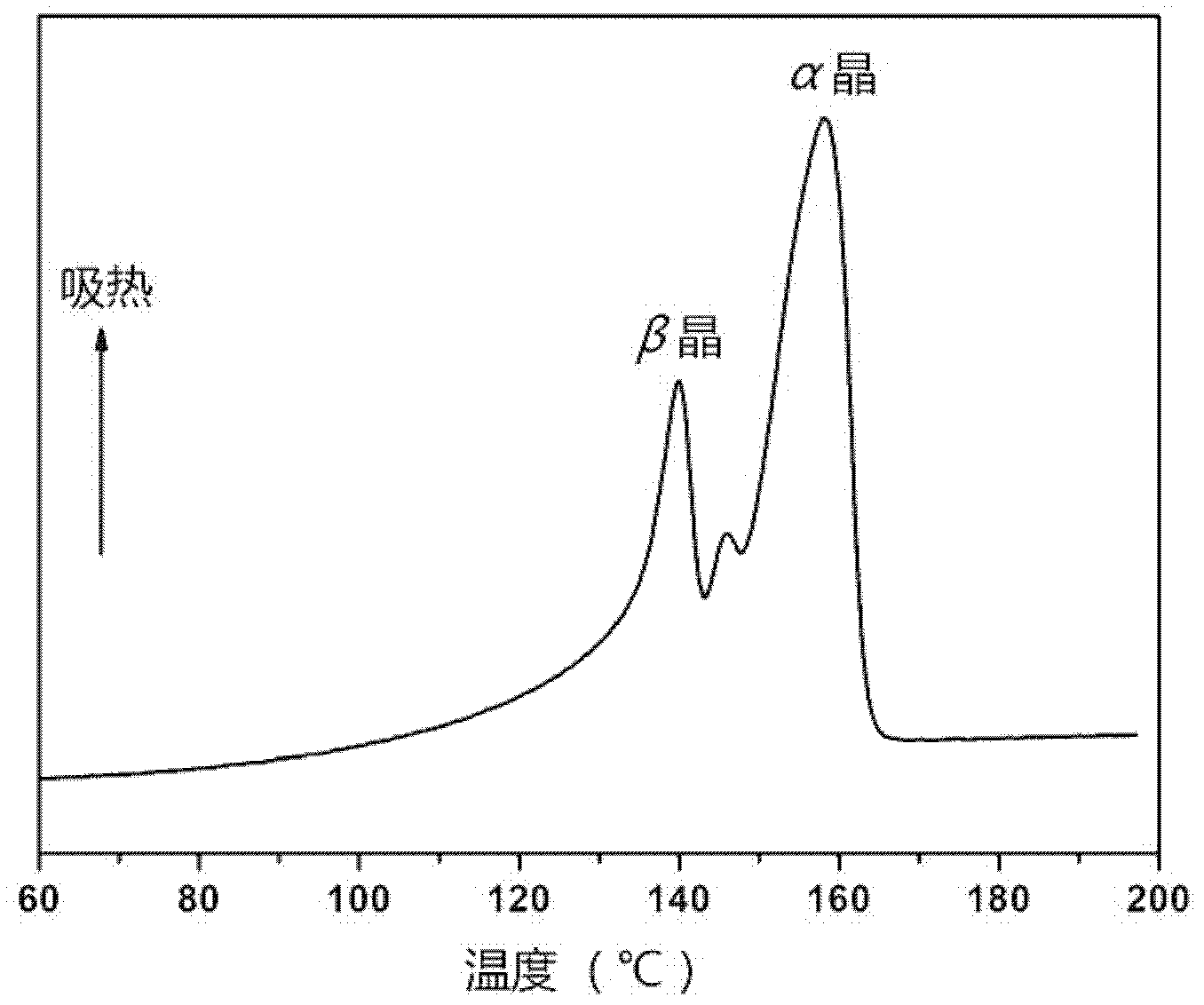

[0044] With 4 kilograms of beta nucleating agent masterbatch, 96.4 kilograms of high melt strength polypropylene (RS1684, Basell Company), 0.1 kilogram of antioxidant 168, 0.2 kilogram of antioxidant 1010, put into extruder after mixing uniformly and extrude For foaming, materials can be continuously added according to the above raw material ratio for continuous production. The extrusion speed of materials is controlled at 40 kg per hour, the injection speed of supercritical carbon dioxide is controlled at 3 kg per hour, and the head pressure is 18 MPa. The head temperature is 160°C, and the water temperature of the underwater pelletizer is controlled at 60°C to obtain expanded polypropylene beads with an expansion ratio of 30 times. The DSC curve of the expanded polypropylene beads is shown in figure 1 .

[0045] The obtained foamed polypropylene beads are put into a thermoforming machine for molding, the steam pressure is 0.4 MPa (welding temperature is 144° C.), the surfac...

Embodiment 2

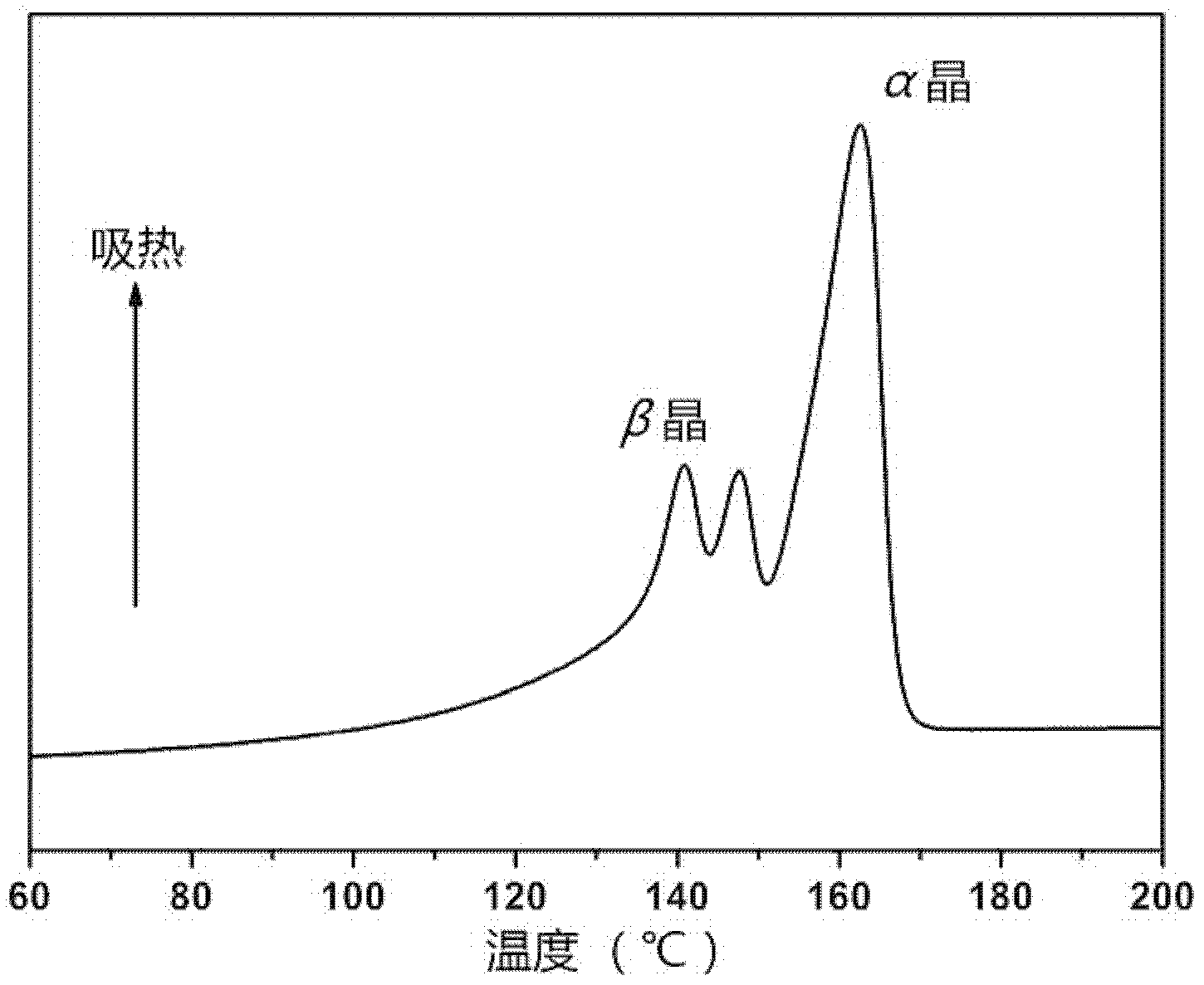

[0047] With 6 kilograms of β-nucleating agent masterbatch, 94.6 kilograms of high melt strength polypropylene (RS1684, Basell Company), 0.1 kilogram of antioxidant 168, 0.2 kilogram of antioxidant 1010, 0.5 kilogram of paraffin, put into extrusion after mixing uniformly Extrusion and foaming in the machine can continuously add materials according to the ratio of the above raw materials for continuous production. The extrusion speed of the materials is controlled at 40 kg per hour, and the injection speed of supercritical carbon dioxide is controlled at 2.8 kg per hour. The pressure is 15MPa, the head temperature is 170°C, and the water temperature of the underwater pelletizer is controlled at 40°C to obtain expanded polypropylene beads with an expansion ratio of 27 times. The DSC curve of the expanded polypropylene beads is shown in image 3 .

[0048] The obtained foamed polypropylene beads are put into a thermoforming machine for molding, the steam pressure is 0.45 MPa (wel...

Embodiment 3

[0050] 4 kg of β-nucleating agent masterbatch, 96.4 kg of high melt strength polypropylene (RS1684, Basell), 0.1 kg of antioxidant 168, 0.2 kg of antioxidant 1010, and 1 kg of black masterbatch were mixed evenly and put into the extruder Extrude and foam in the extruder, the materials can be continuously added according to the ratio of the above raw materials for continuous production, the extrusion speed of the materials is controlled at 40 kg per hour, and the injection speed of supercritical carbon dioxide is controlled at 2.8 kg per hour. The head pressure is 16MPa, the head temperature is 160°C, and the water temperature of the underwater pelletizer is controlled at 60°C to obtain black expanded polypropylene beads with an expansion ratio of 29 times.

[0051] Put the obtained black foamed polypropylene beads into a thermoforming machine for molding, the steam pressure is 0.41MPa (welding temperature: 145°C), the surface of the obtained product is smooth, and the foamed be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com