Polypropylene foam product with low molding pressure and its preparation method

A technology for forming pressure and foamed products, applied in the field of foamed products, can solve the problems of uneven cell structure of polypropylene foamed products, affecting the particle properties of polypropylene foamed products, surface adhesion and other problems, and achieve excellent mechanical properties, The effect of high cell uniformity and uniform cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

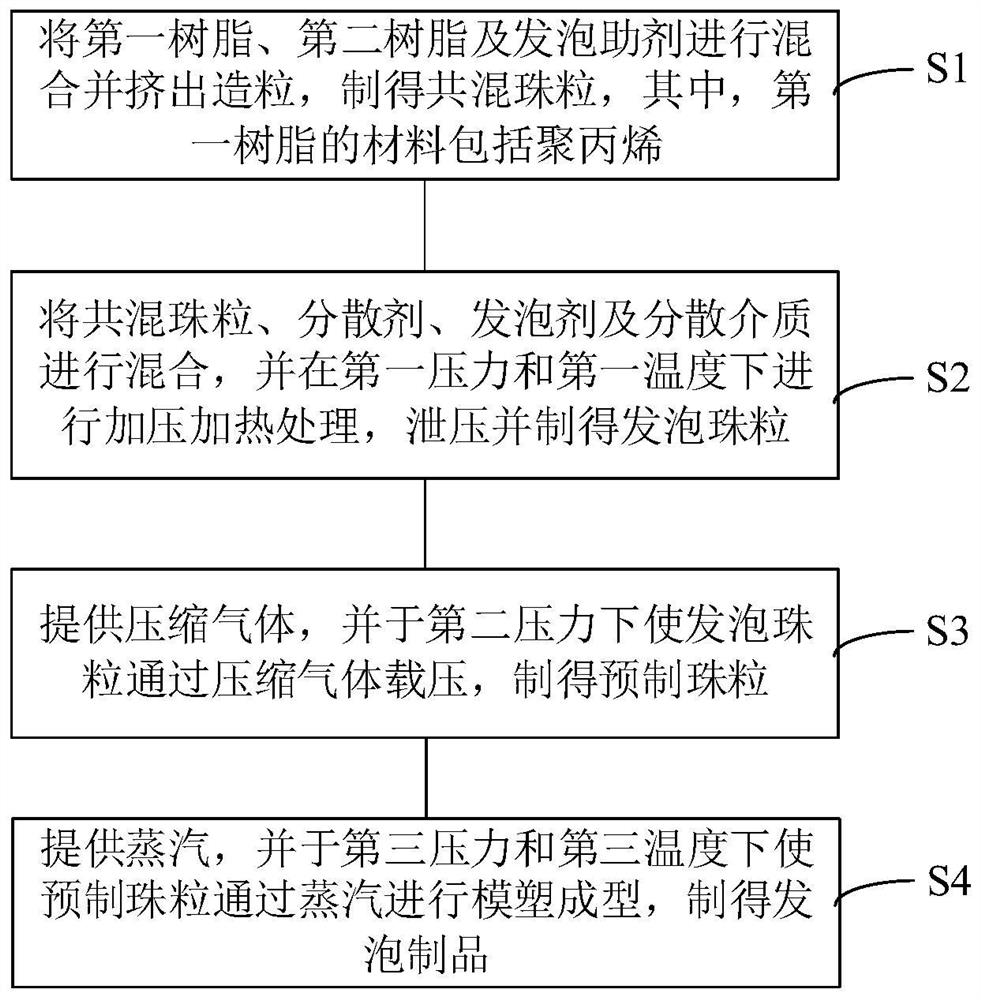

[0035] In order to be able to use lower molding pressure to prepare polypropylene foam products with uniform cell structure and excellent mechanical properties, please refer to figure 1 , The invention provides a polypropylene foam product with low molding pressure and a preparation method thereof.

[0036] Specifically, the preparation method comprises the following steps:

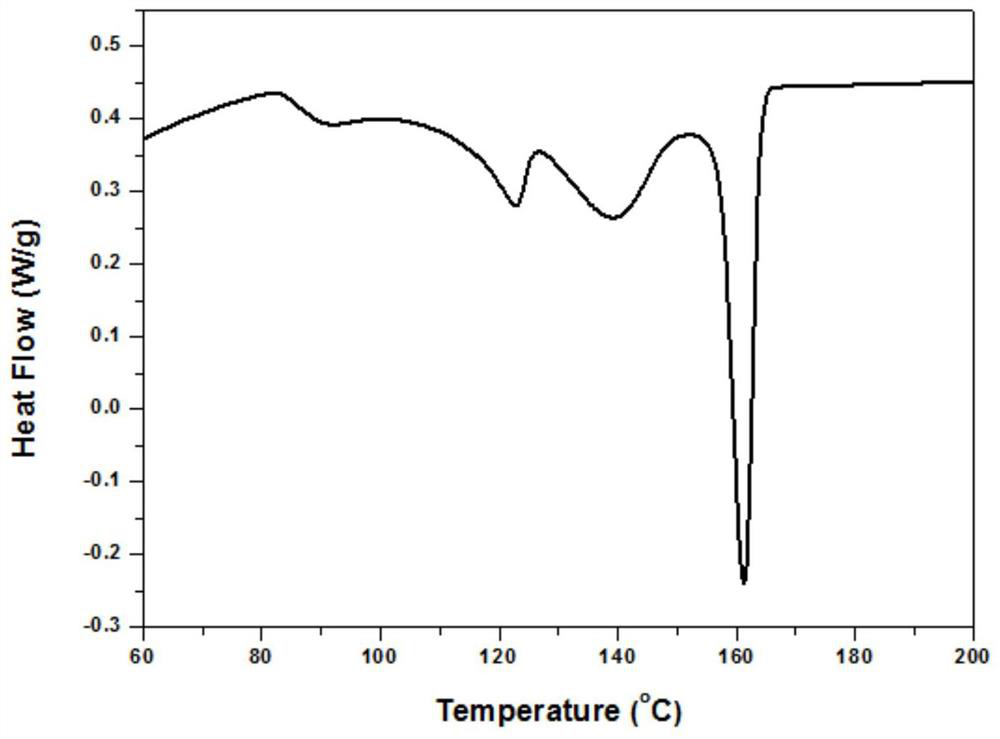

[0037] Step S1: Mix the first resin, the second resin and the foaming aid, extrude and granulate to obtain blended beads, wherein the material of the first resin includes polypropylene resin, and the melting point of the first resin is 140°C to 165°C, and the melting point of the second resin is 15°C to 45°C lower than the melting point of the first resin;

[0038] Step S2: mixing the blended beads, dispersant, foaming agent, and dispersion medium, performing pressurized heat treatment at a first pressure and a first temperature, and then releasing the pressure to obtain foamed beads;

[0039] Step S3: ...

Embodiment approach 1

[0069] Extrusion granulation: 100 parts by weight of polypropylene resin with a melting point of 148°C, 60 parts by weight of LDPE resin with a melting point of 118°C and 5 parts by weight of foaming aid are placed in an extruder and mixed, Extruding, cooling, drawing, and pelletizing to form blended beads, the obtained blended beads have a diameter of 2 mm and an aspect ratio of 2:1.

[0070] Heat and pressure foaming: put the blended beads, dispersant and deionized water in a high-pressure reactor, and fill with 15 parts by weight of CO 2 , pressurized and heated to 2.3 MPa and 149° C., and released the pressure in an instant to release the pressure in the autoclave to atmospheric pressure to obtain foamed beads.

[0071] Loading pressure: place the foamed beads in a pressure tank after drying, fill with compressed air, pressurize under the second pressure and let it stand for a certain period of time to obtain prefabricated beads.

[0072] Molding: Put the pressure-loaded ...

Embodiment approach 2

[0075] This embodiment is basically the same as Embodiment 1, the only difference is:

[0076] Extrusion granulation: Add 100 parts by weight of polypropylene resin with a melting point of 150° C., 50 parts by weight of LDPE resin with a melting point of 118° C. and 10 parts by weight of foaming aid.

[0077] Heating and pressurizing foaming: put the blended beads, dispersant and deionized water in a high-pressure reactor, and fill with 10 parts by weight of CO 2 , pressurized and heated to 2.2MPa and 151°C.

[0078] Loading pressure: place the foamed beads in a pressure tank after drying, fill with compressed air, pressurize under the second pressure and let it stand for a certain period of time to obtain prefabricated beads.

[0079] Molding: Put the pressure-loaded prefabricated beads in a molding machine, and mold them by steam. The pressure of the steam is 0.23MPa, and the temperature of the steam is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com