A kind of anti-yellowing thermoplastic polyurethane foam material and preparation method thereof

A thermoplastic polyurethane and foam material technology, applied in plastic recycling, recycling technology and other directions, can solve the problem of anti-UV additives affecting the stability of thermoplastic polyurethane foam particle performance, anti-UV additives TPU yellowing, anti-UV additives The effect of reducing the effect is reduced, and the effect of good yellowing resistance, controllable foaming density and improving yellowing resistance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

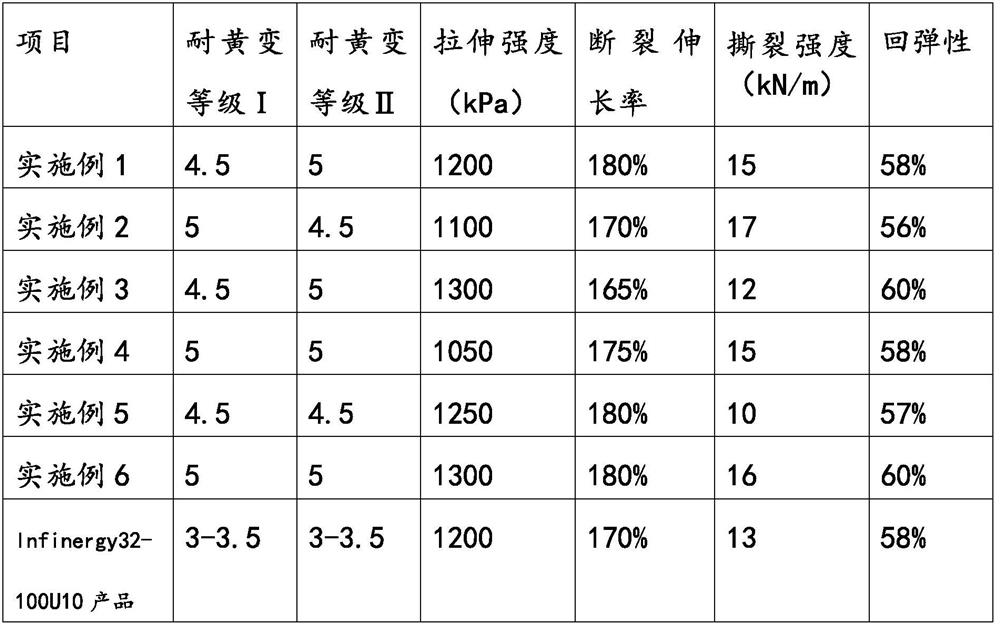

Examples

Embodiment 1

[0043] Preparation of thermoplastic polyurethane foamed material which is resistant to yellowing, comprises hexamethylene diisocyanate 30kg, and 11kg of 1,4-butanediol, 100kg of polybutylene adipate diol and polytetrahydrofuran polyhydric alcohol in a mass ratio of the mixture consisting of a mixture ratio of 1, hindered phenolic antioxidant, benzotriazole ultraviolet absorber and a hindered amine light stabilizer into a twin screw reactive extruder at 150-180 deg.] C prepared by the reaction of the thermoplastic polyurethane elastomer, benzotriazole-based ultraviolet absorbers particularly designations TinuvinP, the specific amount of 0.5% of its total, a hindered amine light stabilizer in an amount of 0.5% of its total amount, specific grades of Tinuvin571, a softening point of the thermoplastic polyurethane elastomer particle was 90 ℃, Shore hardness of 40A, a melt index of 250g / 10min;

[0044] 100 parts by weight of the thermoplastic polyurethane elastomer, 30 parts by weigh...

Embodiment 2

[0047] Preparation of thermoplastic polyurethane foamed material which is resistant to yellowing, comprising a 70kg isophorone diisocyanate, 15kg of 1,4-butanediol, 100kg of polytetrahydrofuran polyol, a hindered phenolic antioxidant, benzo triazole-based ultraviolet absorber and a hindered amine light stabilizer into a twin-screw extruder prepared by reacting a hindered phenolic antioxidant of particular grades of Irganox 1010 antioxidant, specific dosage at 150-200 deg.] C of its total 0.05%, benzotriazole-based ultraviolet absorbers particularly designations Tinuvin 327, specifically the amount of 0.8% of its total, a hindered amine light stabilizer in an amount of 1% of its total specific designation Tinuvin 770 , thermoplastic polyurethane elastomer particle softening point of 160. deg.] C, a Shore hardness of 98A, a melt index of 5g / 10min;

[0048] 100 parts by weight of the thermoplastic polyurethane elastomer, 60 parts by weight of carbon dioxide and 500 parts by weight ...

Embodiment 3

[0051] Preparation of thermoplastic polyurethane foamed material which is resistant to yellowing, comprising a thermoplastic polyurethane elastomer from the hydrogenation of benzene 51kg dimethylene diisocyanate, 1,4-butanediol 12kg, 100kg of polybutylene adipate diol, a hindered phenolic antioxidant, benzotriazole ultraviolet absorber and a hindered amine light stabilizer into a twin-screw extruder prepared by reacting at 150-200 deg.] C, particularly hindered phenolic antioxidant is an anti grades oxygen agent of Irganox 1076, accounting for 0.1% of the total amount of concrete, the benzotriazole-based ultraviolet absorbers particularly designations Tinuvin312, specific dosage 1% of its total, a hindered amine light stabilizer is used in an amount of its total 2%, particularly under the designation Tinuvin 622, a softening point of the thermoplastic polyurethane elastomer particle was 125 deg.] C, a Shore hardness of 85A, a melt index of 100g / 10min;

[0052] 100 parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com