Low-dielectric laser direct structuring composite material suitable for 5G communication and preparation method thereof

A composite material, low-dielectric technology, applied in the field of 5G communication low-dielectric laser direct structuring composite materials and their preparation, can solve the problem that the use of modifiers affects the performance of laser-sensitive additives of LDS materials, affects the LDS performance of composite materials, impact resistance The strength needs to be improved and other problems to achieve the effect of reducing the defects of the finished coating, eliminating the adverse effects and improving the metal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

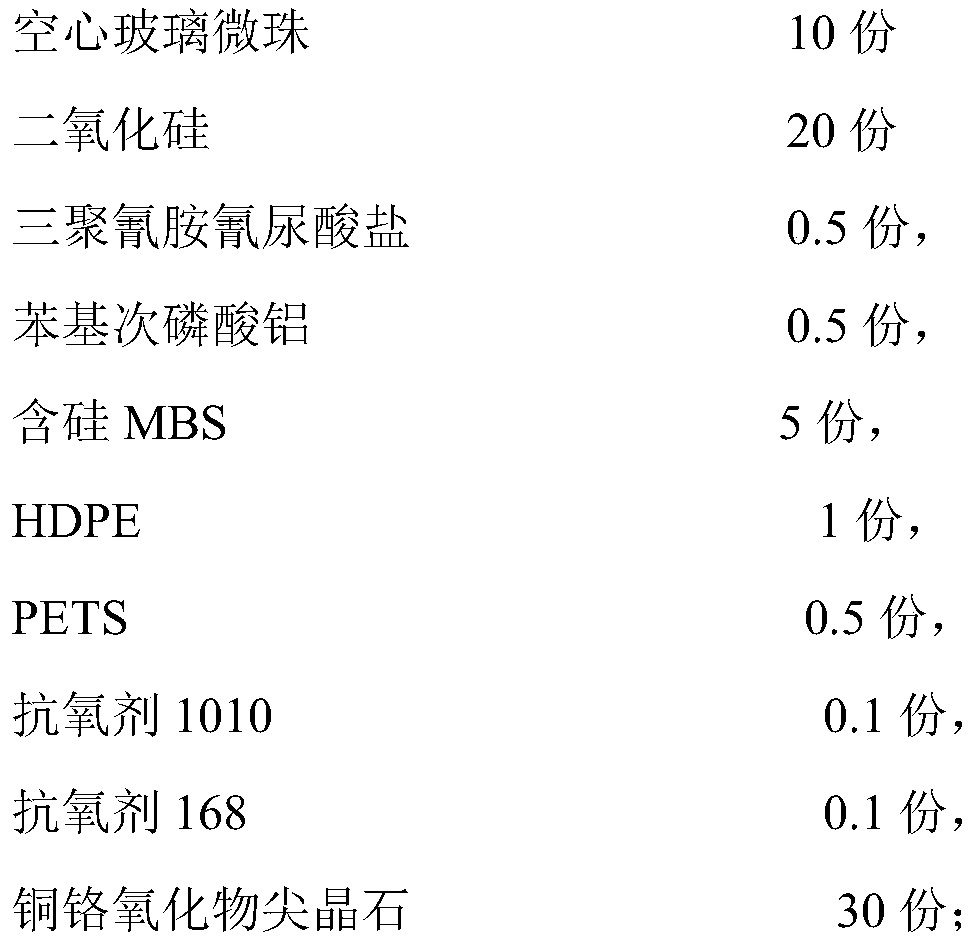

[0048] A low-dielectric laser direct structuring LDS composite material suitable for 5G communication, the LDS composite material consists of the following components by weight:

[0049]

[0050]

[0051] Weigh 63 parts of polyimide, 10 parts of hollow glass microspheres, 20 parts of silicon dioxide, 0.5 part of melamine cyanurate, 0.5 part of aluminum phenyl hypophosphite, 5 parts of silicon-containing MBS, 1 part of HDPE, 0.5 part of PETS, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 30 parts of copper chromium oxide spinel, mix evenly to obtain a mixture, and add the mixture to the main feed of the twin-screw extruder In the process, after melt extrusion, it is drawn from the outlet of the die head, and after water cooling, it is pelletized to obtain LDS composite material particles suitable for 5G communication low dielectric laser direct molding.

[0052] The melt extrusion temperature of the above-mentioned twin-screw extruder is 280-360° C., and the ...

Embodiment 2

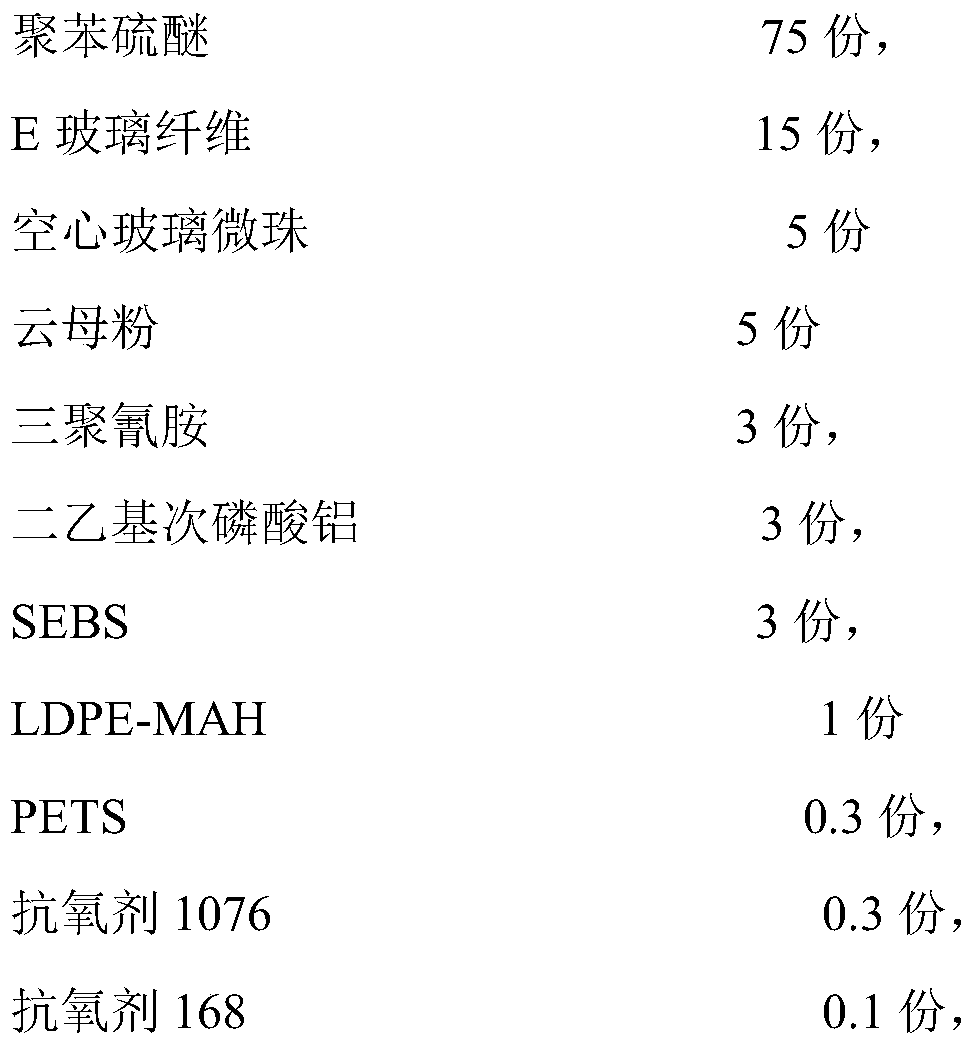

[0054] A low-dielectric laser direct structuring LDS composite material suitable for 5G communication, the LDS composite material consists of the following components by weight:

[0055]

[0056]

[0057] Weigh 75 parts of polyphenylene sulfide, 5 parts of hollow glass microspheres, 5 parts of mica powder, 3 parts of melamine, 3 parts of diethylaluminum hypophosphite, 3 parts of SEBS, 1 part of LDPE-MAH, 0.3 parts of PETS according to parts by weight After 0.3 part, 1076 parts of antioxidant, 1680.1 part of antioxidant, 15 parts of stannous thiocyanate, mix uniformly to obtain compound, add compound in the main feed of twin-screw extruder, add E glass fiber 15 One part is added to the side feed of the twin-screw extruder, and it is drawn out from the outlet of the die after being melted and extruded. After water cooling, it is pelletized to obtain LDS composite material particles suitable for 5G communication low dielectric laser direct molding.

[0058] The melt extrusi...

Embodiment 3

[0060] A low-dielectric laser direct structuring LDS composite material suitable for 5G communication, the LDS composite material consists of the following components by weight:

[0061]

[0062] Weigh 86 parts of polyphenylene ether, 5 parts of hydrotalcite, 5 parts of mica powder, 3 parts of dicyandiamide, 4 parts of aluminum phenyl hypophosphite, 5 parts of POE, 10 parts of HIPS, 0.1 part of PETS, antioxidant After 0.5 parts of 1098, 0.5 parts of antioxidant P-EPQ, and 20 parts of cobalt-nickel arene complex, mix evenly to obtain a mixture, add the mixture to the main feed of the twin-screw extruder, and add 5 parts of hollow E glass fiber , 5 parts of D glass fiber are added to the side feed of the twin-screw extruder, melted and extruded, drawn from the outlet of the die head, water-cooled and pelletized to obtain LDS composite material particles suitable for 5G communication low-dielectric laser direct molding.

[0063] The melt extrusion temperature of the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com