A method of moving and strengthening steel pipe joints on grooved ring mouth plate

A technology of ring plate and groove type, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of brittle cracking of reinforced joints, difficult plate reinforcement, damage, etc., so as to improve the seismic ductility performance, avoid brittle damage, The effect of improving the static strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

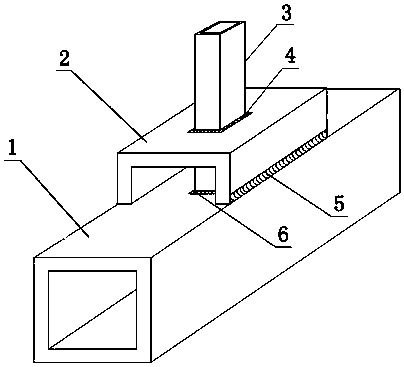

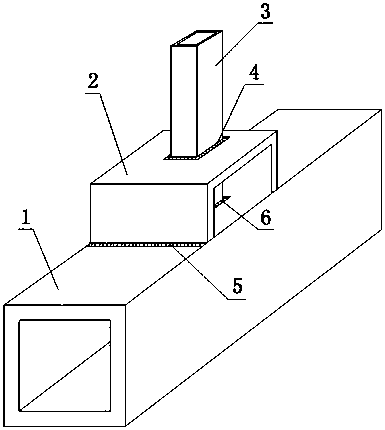

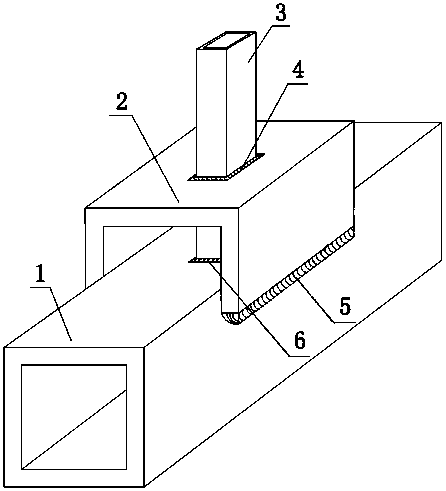

[0019] Option one: in figure 1 , 2 In 3, a method for moving a reinforced steel pipe node on a grooved ring plate, including: a reinforced node supervisor 1, a grooved ring plate 2, a branch pipe 3, a surrounding weld 4, a bilateral connection weld 5, and a central connection Weld seam 6; a branch pipe 3 is vertically welded in the middle of the top surface of the reinforced node main pipe 1; a grooved ring plate 2 is welded on the body of the branch pipe 3, and the grooved ring plate 2 is along the axis of the main pipe or perpendicular to Welding in the axial direction of the main pipe is on both sides of the main pipe 1 of the reinforced node or on the upper surface of the main pipe 1 of the reinforced node, thereby forming a surrounding weld 4, a central connection weld 6 and a bilateral connection weld 5; when the groove type When the annular plate 2 is arranged along the axial direction of the main tube 1 of the reinforced node, and the surface width of the main tube 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com