Continuous degassing device for fluidic, highly-viscosity or cream-like polyester

一种高粘性、设备的技术,应用在反应器领域,能够解决没有找到转子操作的过程参数过程调节、转子构造昂贵、驱动装置不令人满意等问题,达到改进操作安全性、提高强度、减小质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

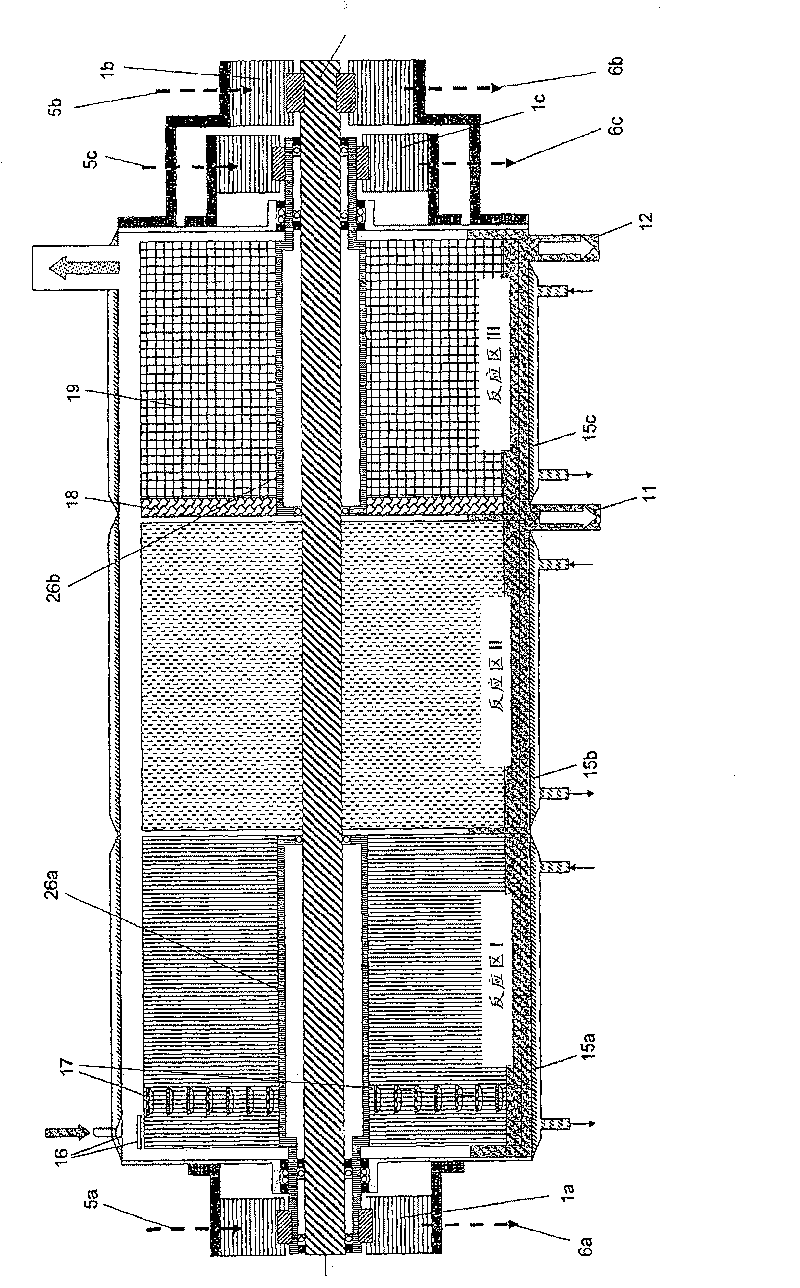

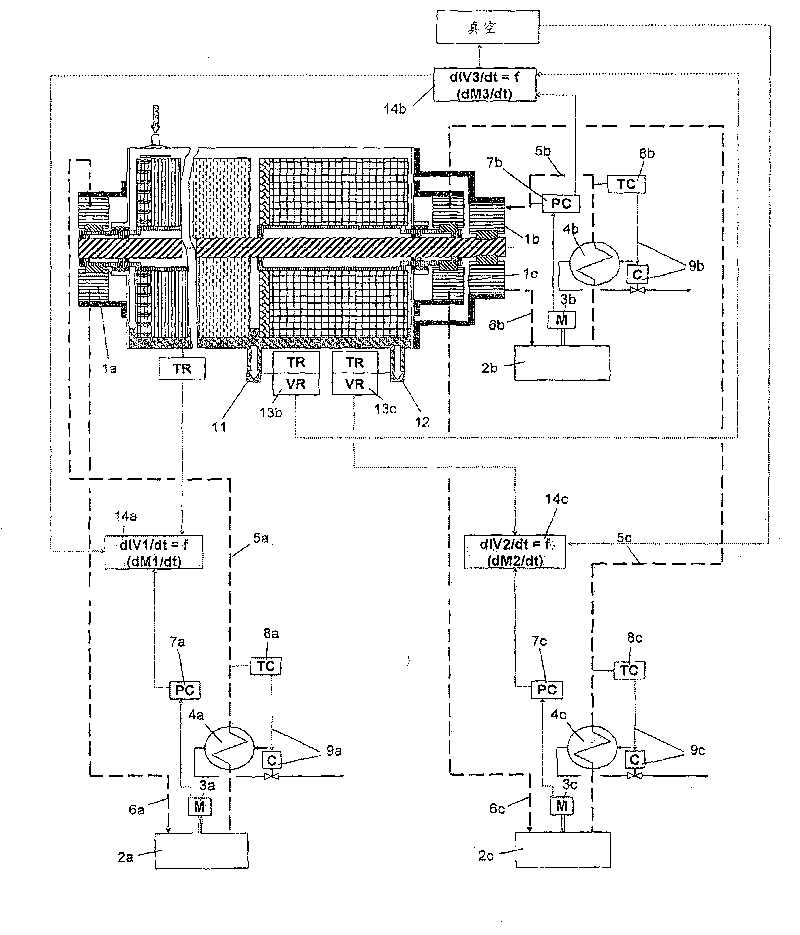

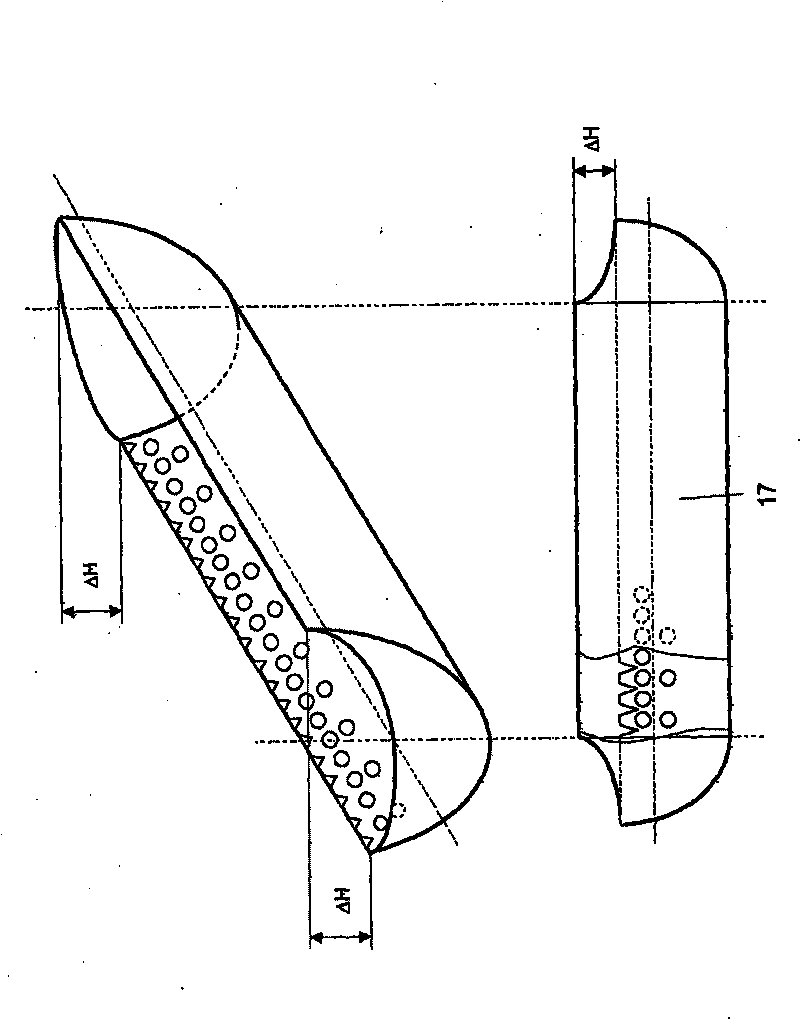

[0047] figure 1 shows a reactor with three reaction zones for continuous degassing of reaction products made from carboxylic acids of a multifunctional alcohol. The reactor has three hydraulic drives 1a, 1b and 1c for the three rotors of reaction zones I, II and III. The drive means for each rotor are respectively connected to the hydraulic system via a feed line 5 and a return line 6 . The hydraulic drive is characterized by a low mass, a controllably low rotational speed, an adjustable reaction using the operating parameters of the drive. The rotor of reaction zone II is fastened on a straight main shaft 25 which is supported on the left in the inner bearing of the hollow shaft of the rotor of reaction zone I and on the right in the inner bearing of the rotor of reaction zone III. The rotor of reaction zone I is fastened on a hollow shaft 26a which is supported on the left side on the end face of the reactor and on the right side on the main shaft. The rotor of reaction z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com