A kind of high-strength stress corrosion-resistant al-zn-mg-cu alloy and preparation method thereof

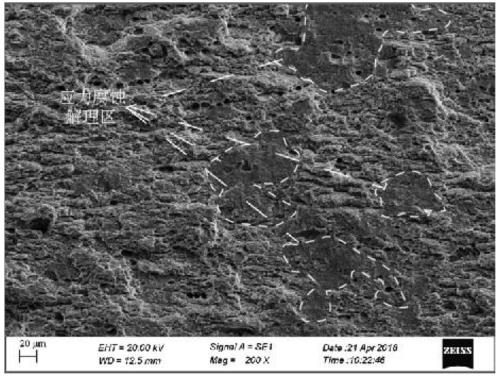

A technology of stress corrosion resistance and alloy is applied in the field of high-strength stress corrosion resistance Al-Zn-Mg-Cu alloy for rail transit and its preparation field, which can solve the problems of poor stress corrosion resistance and achieve improved service life, good mechanical properties and Stress corrosion resistance, effect of uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

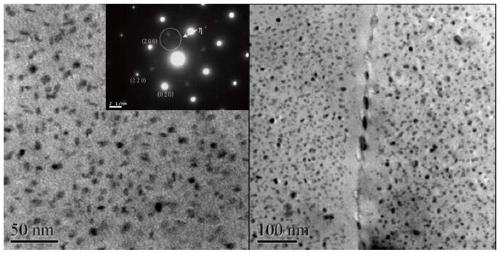

[0033] A certain alloy composition (mass percentage) is as follows: Zn content is 4.5%, Mg content is 1.5%, Mn content is 0.35%, Cu content is 0.12%, Cr content is 0.15%, Zr content is 0.2%, Ti content is 0.05%, The balance is aluminum and the alloy has a Zn / Mg ratio of 3. After the alloy is homogenized at 220°C / 5h, 330°C / 20h, and 450°C / 12h, the alloy is extruded and deformed. Before extrusion, the alloy is subjected to heat preservation treatment at 450°C. The ratio is 17%, the strain rate is 3.00s -1, after extrusion deformation, the alloy was subjected to two-stage solution treatment at 430°C / 0.5h and 475°C / 1.5h. After solid solution treatment, the alloy is quenched, the quenching medium is water, and the quenching temperature is 15°C, and then the alloy is quickly transferred to a constant temperature aging furnace for low-temperature pre-aging treatment at 60°C / 24h, 95°C / 24h and 150°C / 24h three-stage aging treatment. After treatment, the tensile strength of the alloy ...

Embodiment 2

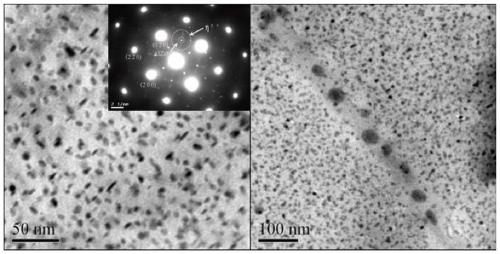

[0037] A certain alloy composition (mass percentage) is as follows: Zn content is 5%, Mg content is 2%, Mn content is 0.25%, Cu content is 0.2%, Cr content is 0.12%, Zr content is 0.18%, Ti content is 0.1%, The balance is aluminum and the alloy has a Zn / Mg ratio of 2.5. The alloy has been homogenized at 250°C / 5h, 360°C / 20h, and 475°C / 12h. After the homogenization treatment, the alloy is extruded and deformed. Before extrusion, the alloy is subjected to heat preservation treatment at 460°C. The extrusion temperature is 350°C, the extrusion ratio is 17%, and the strain rate is 4.00s. -1 , after extrusion deformation, the alloy was subjected to two-stage solution treatment at 430°C / 0.5h and 475°C / 1.5h. After solution treatment, the alloy is quenched, the quenching medium is water, and the quenching temperature is 20°C, and then the alloy is quickly transferred to a constant temperature aging furnace for low-temperature pre-aging treatment at 65°C / 24h, 100°C / 24h and 150°C / 24h t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com