Assembly structure of prefabricated concrete beam and concrete-filled steel tube column

A technology of concrete-filled steel tube columns and prefabricated concrete, which is applied in building construction and construction, and can solve the problems of steel beams that are prone to buckling, fire performance, large cross-sectional size of joint joints, and complicated binding and connection of steel bars, so as to improve the energy of joints Dissipative capacity, convenient and fast construction, reliable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

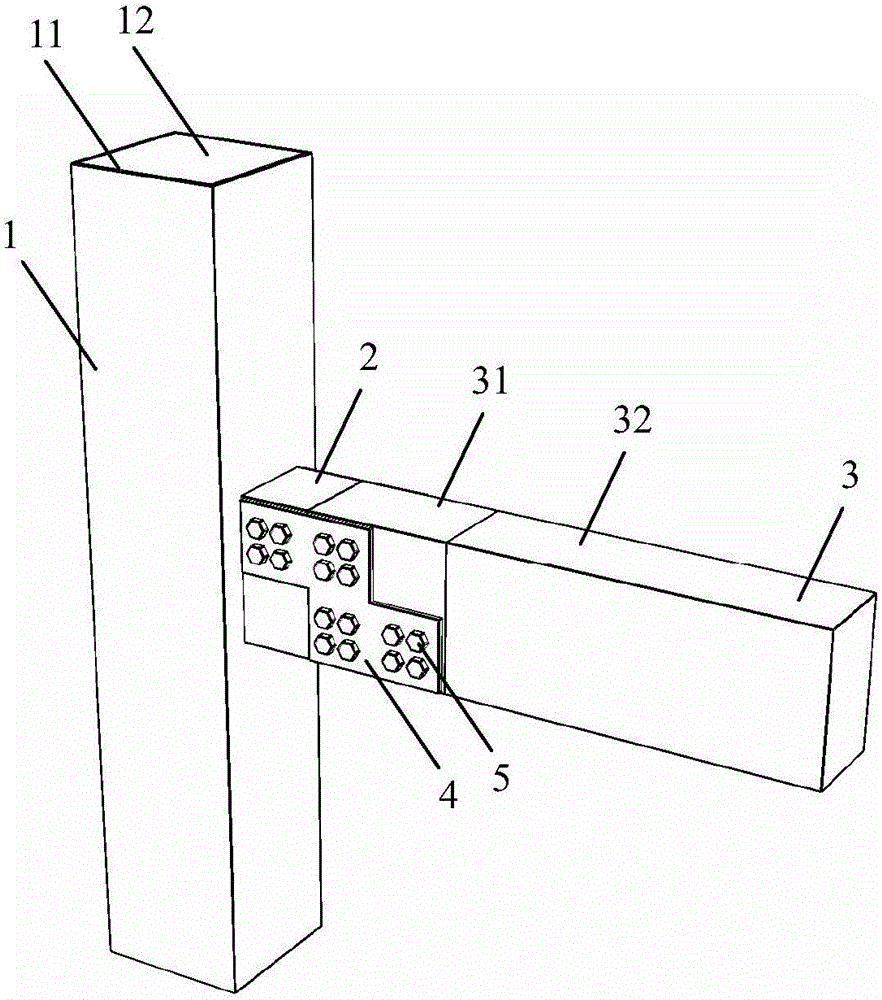

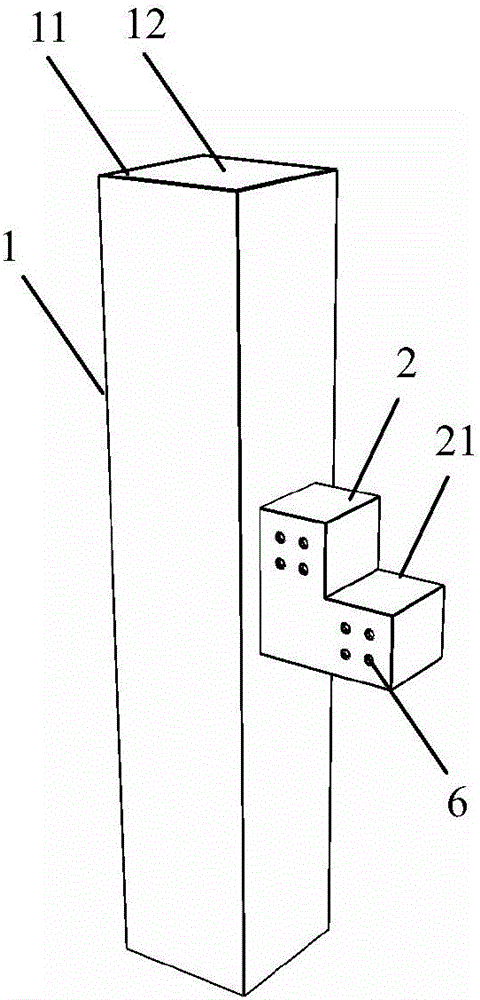

[0031] see Figure 1 to Figure 9 As shown, an assembly structure of precast concrete beams and steel tube concrete columns, including steel tube concrete columns 1, steel tube concrete corbels 2, precast concrete beams 3, and connecting plates 4;

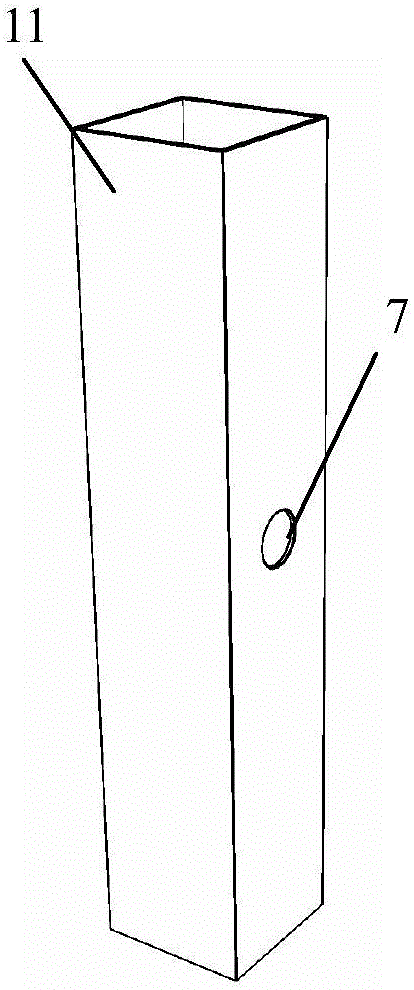

[0032] The steel pipe concrete column 1 is composed of a steel pipe column 11 and a concrete column 12 filled into the steel pipe column 11;

[0033] The side of the concrete-filled steel pipe column 1 is welded with a concrete-filled steel pipe corbel 2, and the concrete-filled steel pipe corbel 2 is stepped; the concrete-filled steel pipe corbel 2 includes corbel steel 21 and corbel concrete 22 filled inside the corbel steel 21; the corbel A plurality of tension bolt holes 6 are arranged on the side of the section steel 21;

[0034] The precast concrete beam 3 includes pre-embedded section steel 31 at the beam end and prefabricated reinforced concrete 32. The pre-embedded section steel 31 at the beam end is in the shape of an inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com