Lattice type single-row reinforcement crisscross-section concrete column and manufacture method thereof

A concrete column and cross-shaped technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of poor integrity of village houses, weak seismic capacity, poor thermal insulation performance, etc. Low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

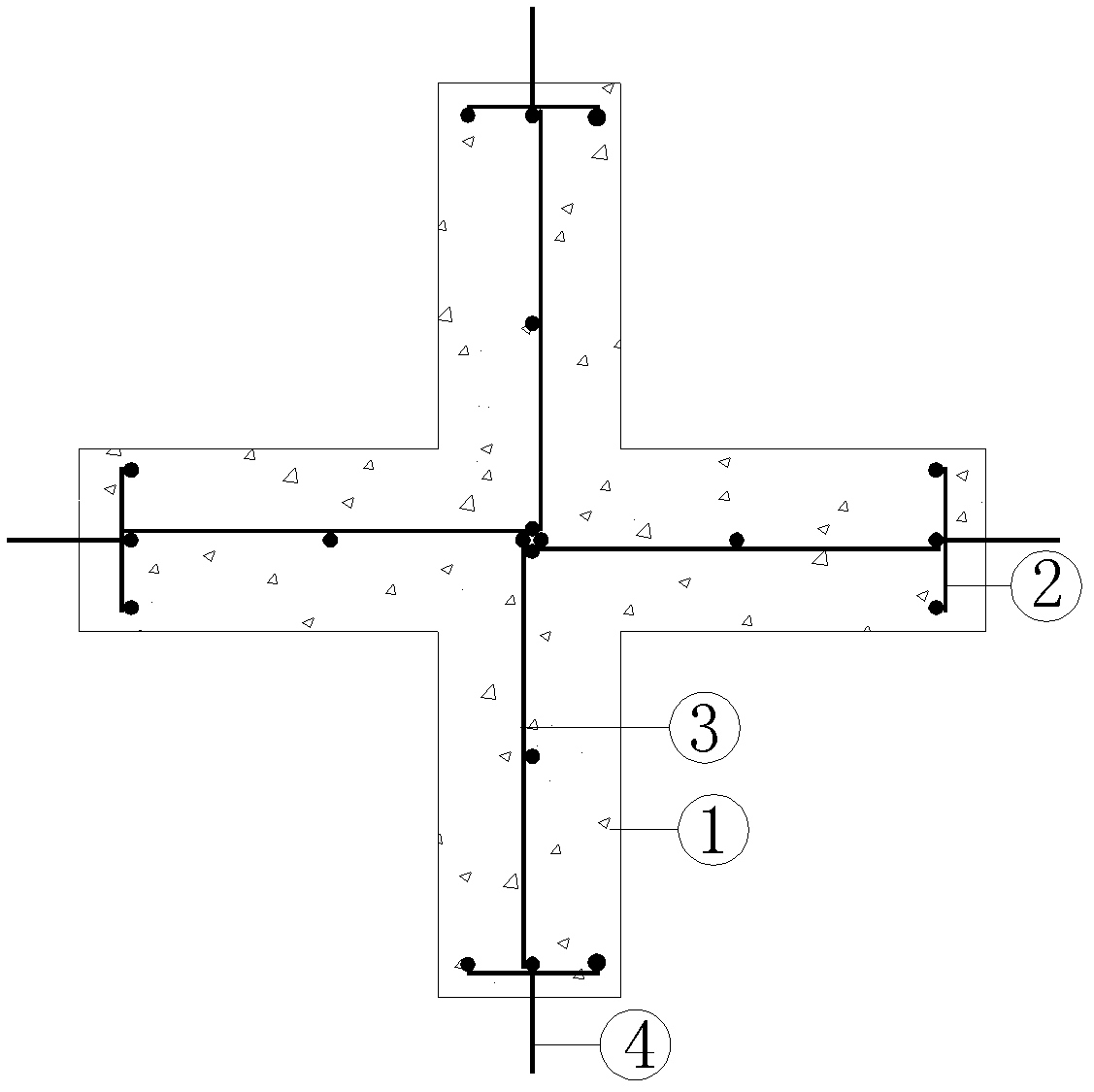

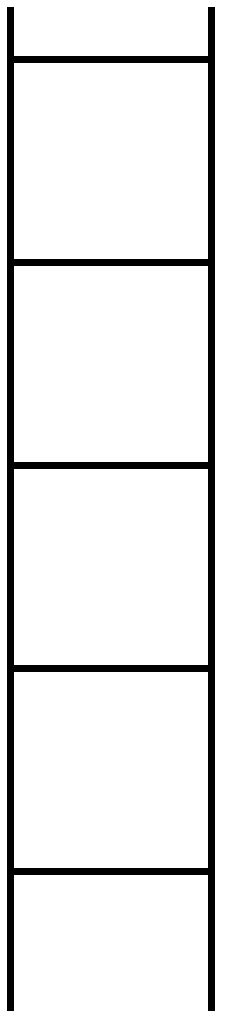

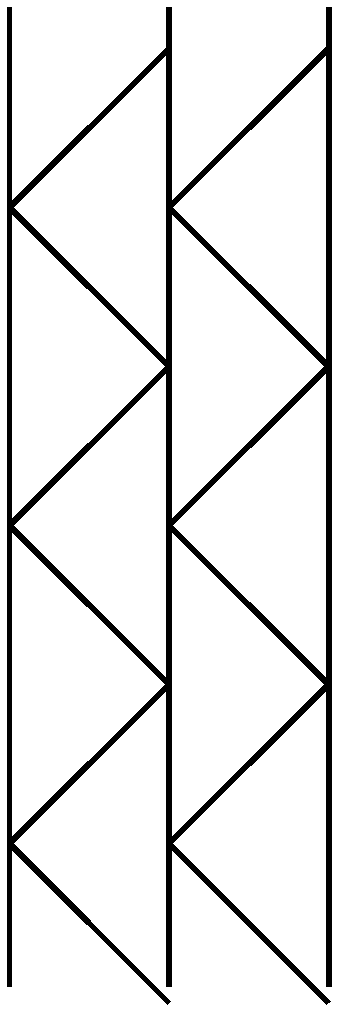

[0030] like Figure 1 to Figure 5 The lattice-type single-row reinforcement cross-section concrete column is composed of concrete 1, ladder grid reinforcement mesh 2, lattice single-row reinforcement mesh 3, and tie reinforcement 4. The reinforcement skeleton of the cross-shaped column is ten Four pieces of lattice single-row reinforcement mesh 3 are welded into cross-shaped limbs; trapezoidal reinforcement mesh 2 is welded at the ends of cross-shaped lattice single-row reinforcement mesh limbs, and the lattice single-row reinforcement mesh 3 The plane passes through the central axis of the ladder-like steel mesh 2; the ladder-like steel mesh 2 is welded into a ladder-like shape by two vertical steel bars and several horizontal steel bars; the lattice single-row reinforcement mesh 3 is located On the center line of the section, it is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com