Honeycomb hollowed-out grating tubular double-steel-plate concrete composite shear wall and preparation method thereof

A combined shear wall and steel tube concrete technology, applied in the direction of walls, floors, building components, etc., can solve the problems of difficult connection construction, heavy hoisting weight, and narrow internal space, so as to improve the strength and ductility of concrete inside the tube and strengthen the outside of the plane. The ability to buckle and break, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

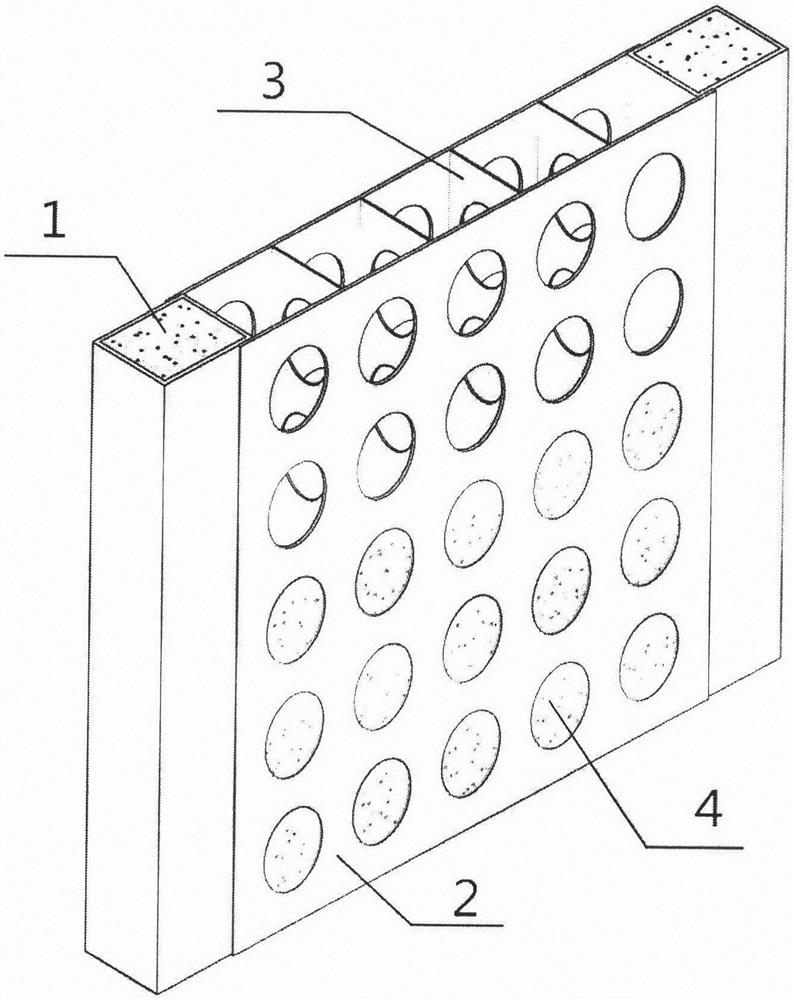

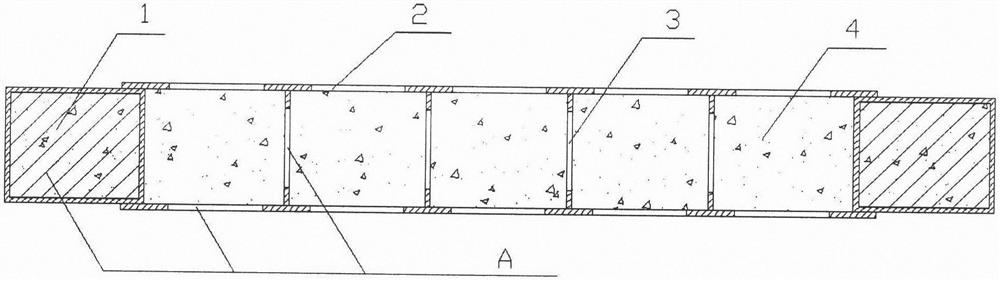

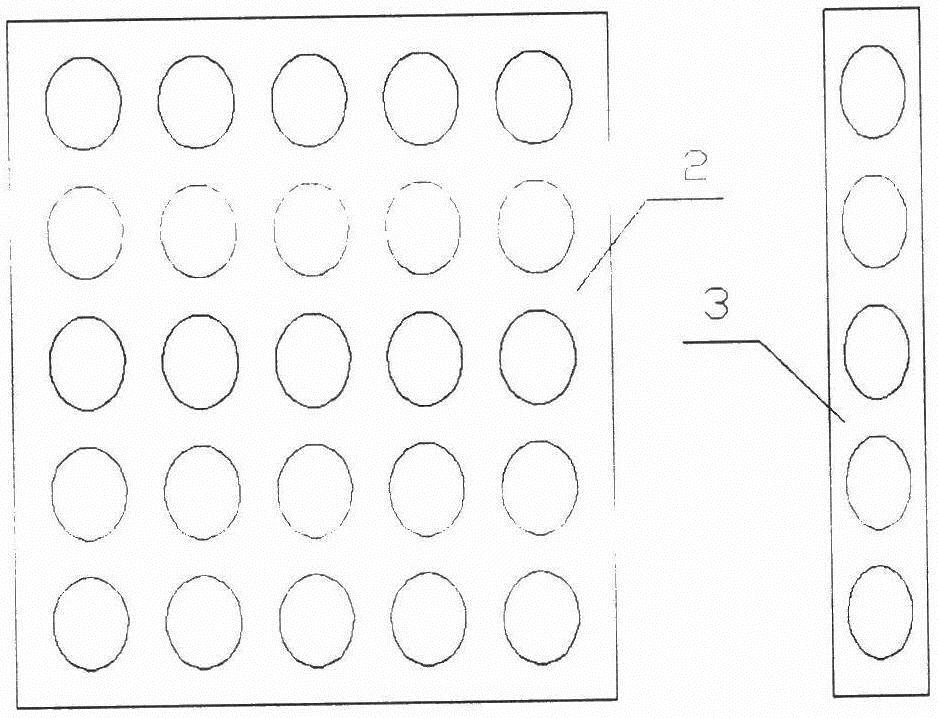

[0048] A honeycomb hollowed-out grid tubular double-steel plate concrete composite shear wall of the present invention comprises a steel pipe concrete end column 1, a honeycomb hollowed out steel plate 2, a honeycomb hole tie steel plate 3, concrete in the pipe 4, and a small wall sealing formwork 5 and reinforced concrete floor slab 6, which are characterized in that two rectangular steel pipe concrete end columns 1 are arranged in front and rear of two honeycomb hollow steel plates 2, and the honeycomb hollow steel plates 2 are thin steel plates with holes arranged in orthogonal arrays. Steel plate, a number of honeycomb hole tie steel plates 3 are evenly arranged between the front and rear two honeycomb hollow steel plates 2, and the steel pipe concrete end column 1, honeycomb hollow steel plate 2 and honeycomb hole tie steel plate 3 are welded and connected as a whole to form a honeycomb hollow grid tubular wall panel A, a plurality of wall sealing hole-to-draw small templa...

Embodiment 2

[0053] A method for preparing a honeycomb hollow-out grid tubular double-steel plate concrete composite shear wall, comprising the following steps:

[0054] Step 1: In the steel structure processing factory, according to the design requirements, the rectangular steel pipe of the steel pipe concrete end column 1 is cut, and the honeycomb hollow steel plate 2 and the honeycomb hole tie steel plate 3 are processed in the factory. Two rectangular steel tubes of steel tube concrete end columns 1, two front and rear honeycomb hollow steel plates 2 and several honeycomb hole tie steel plates 3 in the middle are firmly welded to form a honeycomb hollow grid tubular wall panel A;

[0055] Step 2: Transport the honeycomb hollow grid tubular wall panel A to the construction site of the super high-rise building, hoist it in place, and weld and assemble multiple honeycomb hollow grid tubular wall panels A to form L-shaped, T-shaped and cross-shaped shear walls. Install the wall sealing hol...

Embodiment 3

[0059] A 100-meter super high-rise residential building has a seismic intensity of 8 degrees. In order to speed up the construction and other reasons, a honeycomb hollowed-out grid tubular double-steel plate concrete composite shear wall system is adopted. The number of floors in the building is 33. The shear wall of the building The thickness is 360-180mm.

[0060] The honeycomb hollow grid tubular double steel plate concrete composite shear wall is composed of two rectangular steel tube concrete end columns, two front and rear honeycomb hollow steel plates and several internal honeycomb hole tie steel plates to form a steel structure honeycomb hollow grid Tubular wall panels, welded multi-piece grid steel structure grid tube wall panels to form L-shaped, T-shaped and cross-shaped shear walls, and high-performance concrete is poured into the honeycomb hollow grid tubular wall panels to form a honeycomb hollow grid tubular Double steel plate concrete composite shear wall syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com