Quick construction method for high-rise buildings

A fast technology for high-rise buildings, applied in the processing of building materials, construction, and on-site preparation of building components. The effect of large and many safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is further described in conjunction with the following examples.

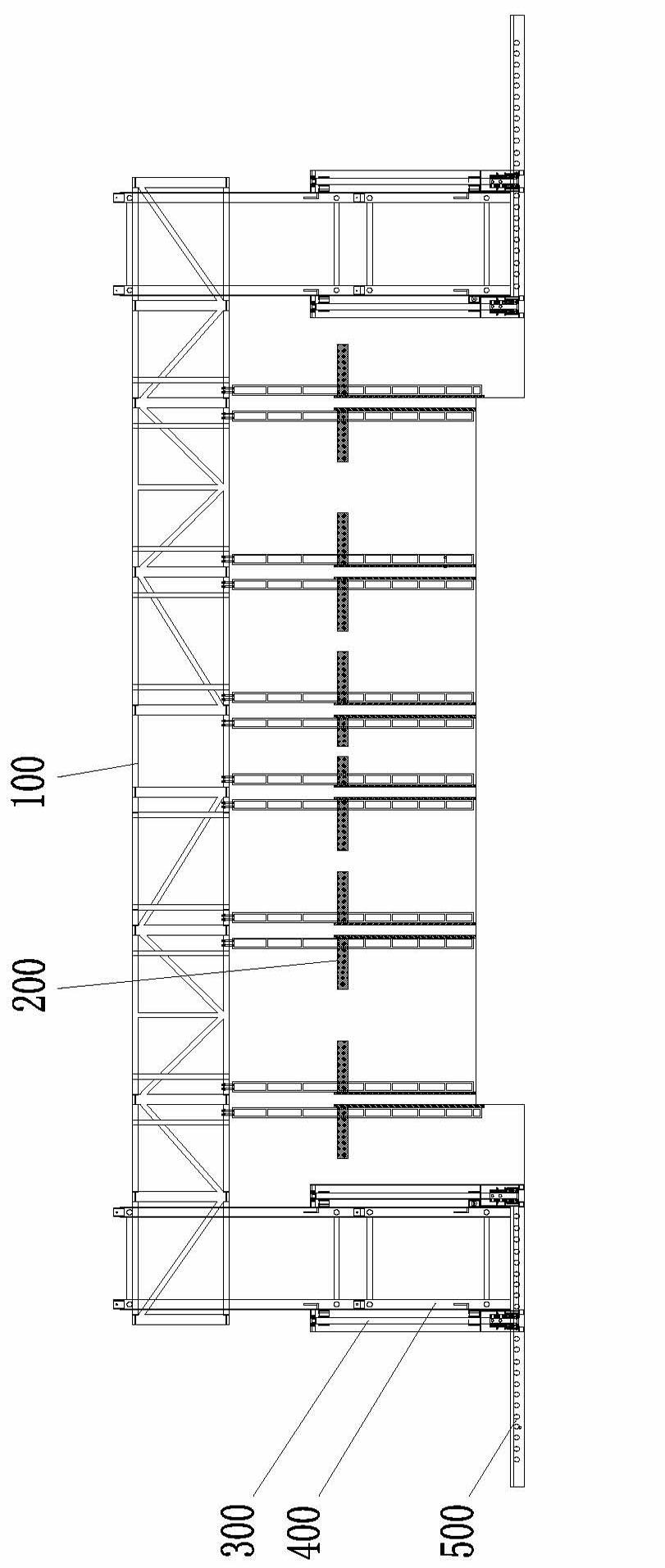

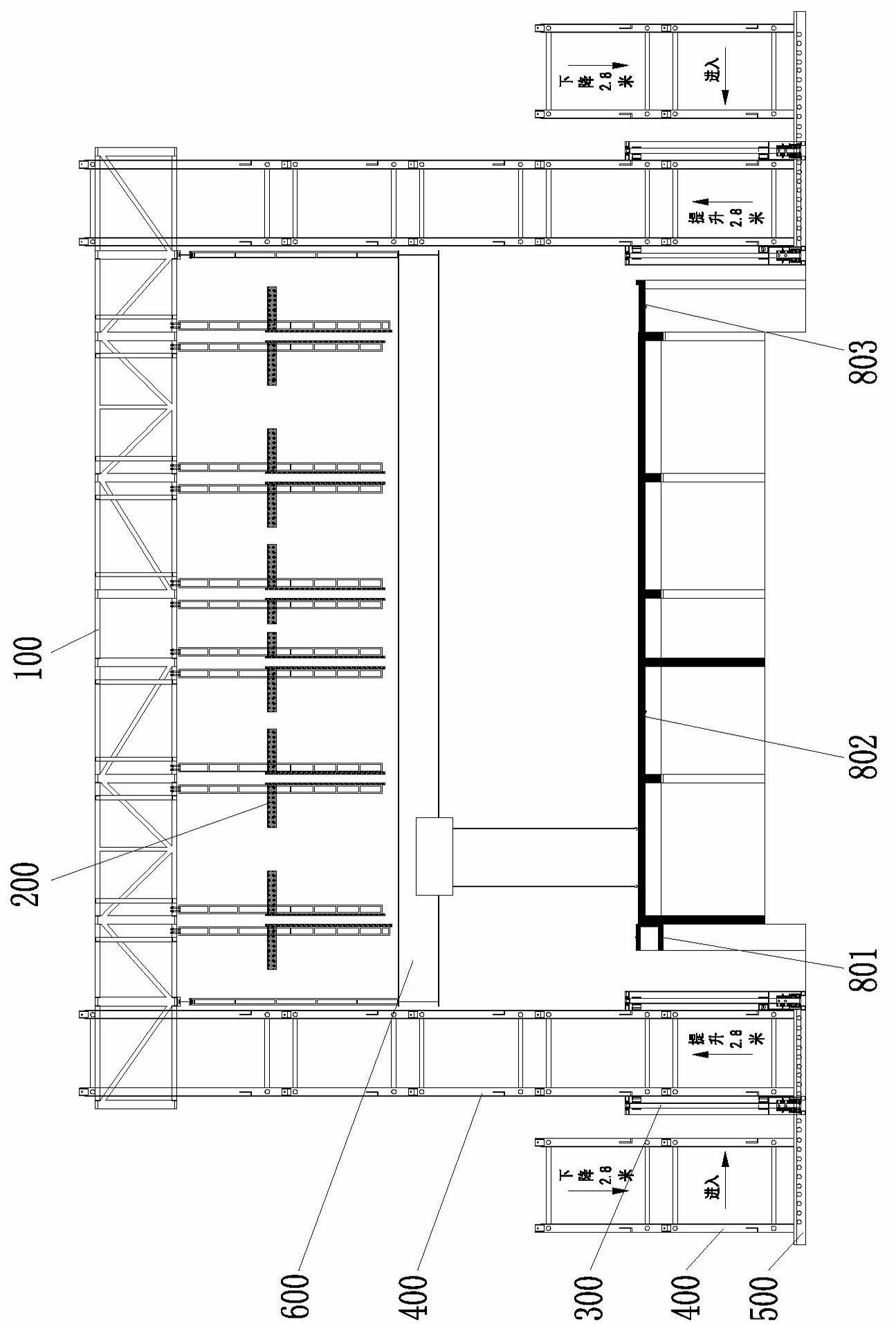

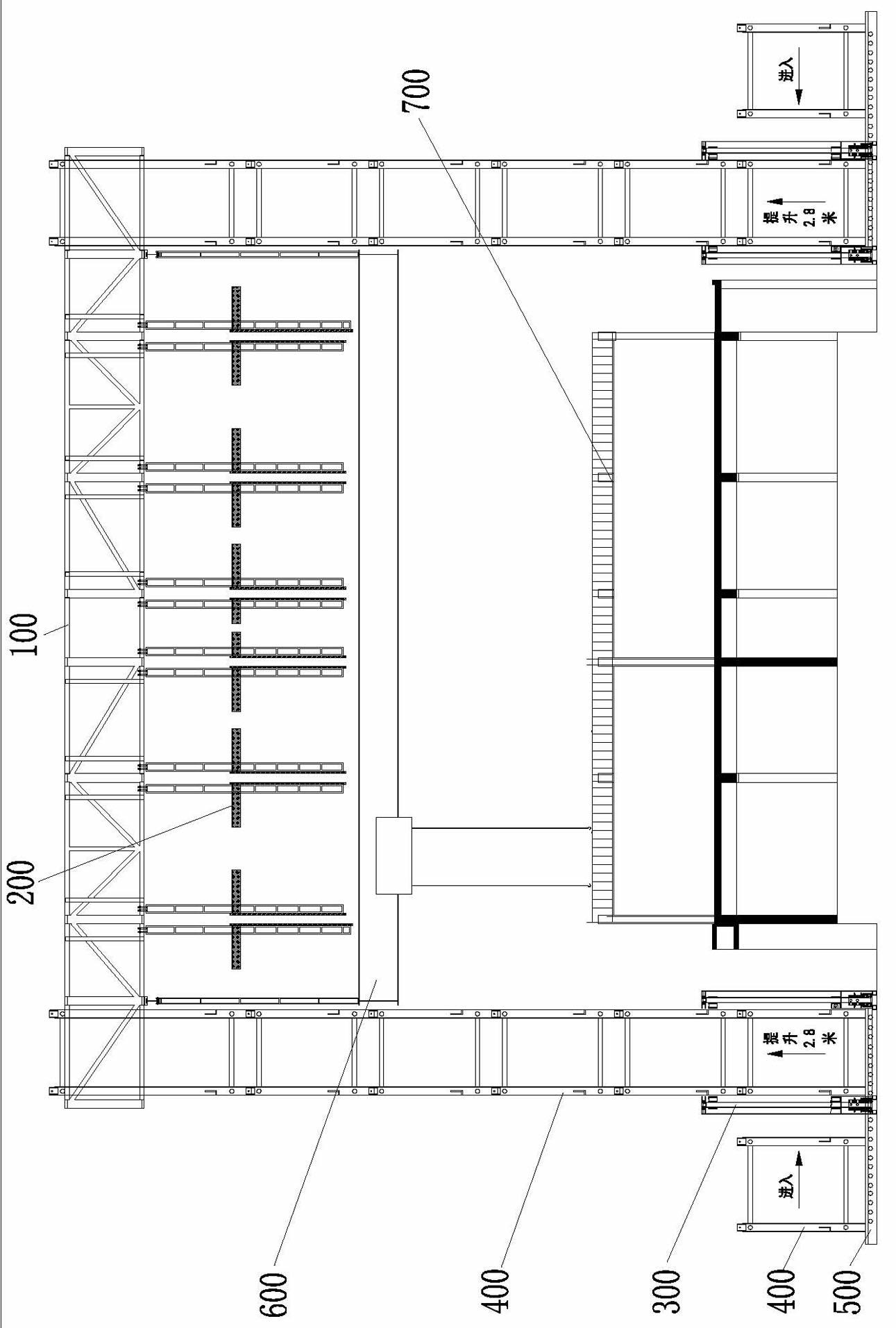

[0053] The specific embodiment of the method for fast construction of high-rise building of the present invention, as Figure 1 to Figure 8 shown, including the following steps:

[0054] Step 1, hoisting the overall lifting device to the construction site where the building ground has been prepared according to the architectural design drawing, and lifting and assembling the lifting bracket 400; wherein the overall lifting device is a four-screw lifting device 300; specifically, the steps One side of the four-screw lifting device 300 is provided with a storage lifting device, and a lifting support conveying device 500 used in conjunction with the four-screw lifting device 300 and the storage lifting device, the lifting support 400 It is hoisted by the hoisting equipment 600 into the storage lifting device, and then transported into the four-screw lifting device 300 by the lifting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com