Structure and construction method of cast-in-site style welded steel frame composite concrete shear wall

A concrete shear wall, cast-in-place technology, applied in building structures, walls, building components, etc., can solve problems such as costing a huge amount of money, a lot of construction waste, and difficulty in solving linear thermal bridges at the floor, to improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

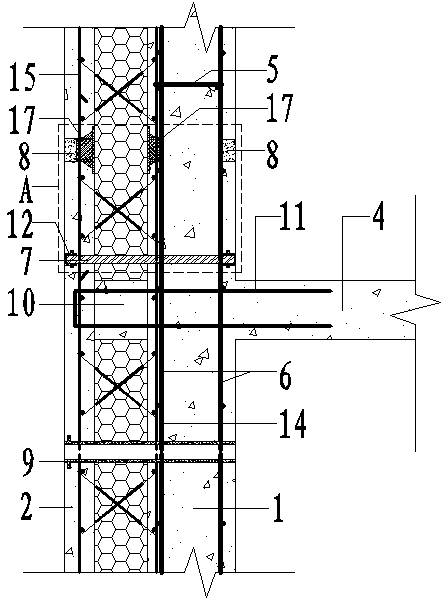

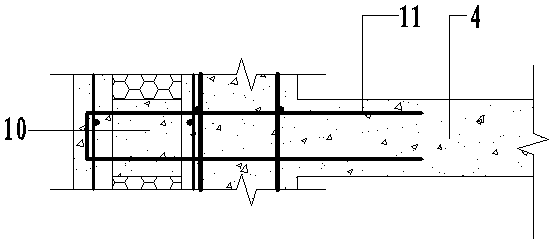

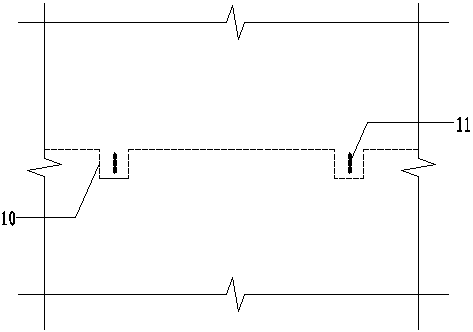

[0039] The present invention is a structure of a cast-in-place welded grid frame composite concrete shear wall, and plastic pads are arranged between the welded steel grids on both sides and the insulation board to control the position of the insulation layer well; The cross-sectional size of the composite wall; the method of setting cantilevered holes and cantilevered steel bars at the floor slab solves the problem of linear thermal bridges at the floor slab; the non-combustible pipe with a water-stop ring on the outside is used for the wall-through casing to avoid the phenomenon of water seepage ;By controlling the diameter, slenderness ratio, angle, etc. of the obliquely inserted steel bar, the stability of the obliquely inserted steel bar is improved, so that it can transmit the external forces of different directions borne by the thinner side concrete layer to the thicker side concrete layer; strict Control the thickness of the concrete on both sides and the material and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com