A processing technology of internal combustion engine radiator

A processing technology and radiator technology, applied in the direction of machine/engine, engine cooling, metal processing equipment, etc., can solve the problems of radiator finished product output restriction, suppressing pass rate limitation, affecting appearance, etc., to achieve weld seam smoothness and The appearance is improved, the welding quality is stable and reliable, and the effect of improving the automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 A kind of processing technology of internal combustion engine radiator

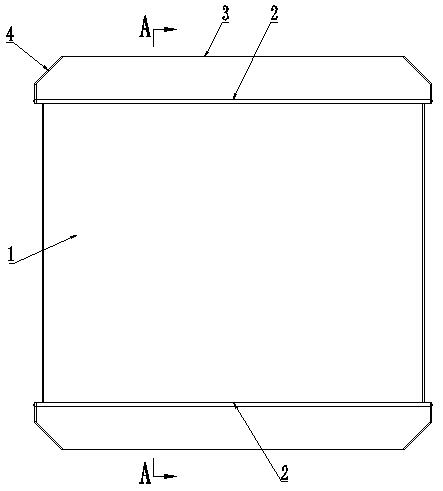

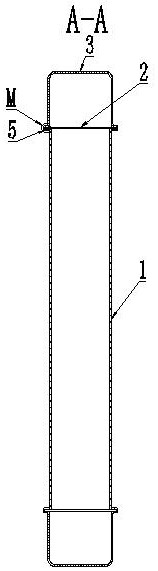

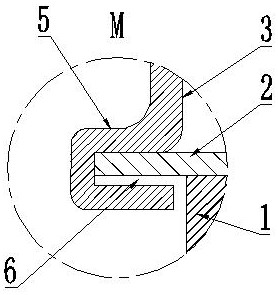

[0043] Such as figure 1 , 2 , 3, 4, 5 and 6 show together, the present invention provides a kind of processing technology of internal combustion engine radiator, comprises the following steps:

[0044] S1. Material selection: the main piece 2, the end plate of the water chamber 4 and the heat dissipation belt are all made of double-sided composite aluminum material. The matrix in the middle of the aluminum material is a 3003 aluminum alloy layer, and the upper and lower layers of the aluminum material are 4045 or 4343 brazing layers. , the tensile strength of the composite aluminum plate is 170Mpa ~ 210Mpa, and the elongation after breaking is 8% ~ 10%; the water chamber 3, heat pipe and reinforcement plate are all made of 3003 aluminum alloy;

[0045] S2, blanking: the main piece 2 is stamped and formed, and a long hole is opened on the main piece 2, and the gap between the opening ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com