Structural steel two-stage heating hardening and tempering process method

A technology of two-stage heating and process method, which is applied in the field of structural steel quenching and tempering, and can solve the problems of undetected quenching and tempering process of structural steel workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

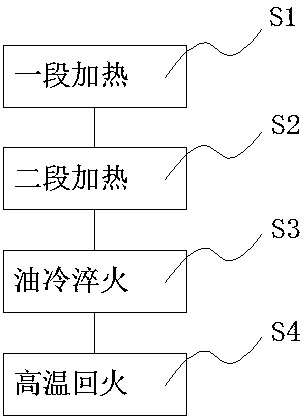

[0027] Embodiment one, with reference to figure 1 , a second-stage heating and tempering process method for structural steel, comprising the steps of:

[0028] S1, one-stage heating, heating the structural steel workpiece as a whole, and the first-stage heating temperature is controlled at the lower limit of the normal quenching temperature of the structural steel workpiece; it can refine the grain, reduce the internal stress, greatly reduce the probability of cracks, and reduce deformation and decarburization;

[0029] S2, two-stage heating, secondary heating of the structural steel workpiece as a whole, the second-stage heating temperature is controlled at the upper limit of the normal quenching temperature of the structural steel workpiece; the second stage selects the upper limit of the quenching temperature to ensure the hardening of the larger part of the cross-sectional size of the workpiece effect, and prevent the temperature from dropping too low during the transfer o...

Embodiment 2

[0039] Embodiment 2, this embodiment adds the following technical features on the basis of Embodiment 1:

[0040] Before the step S1, the structural steel workpiece is pretreated as a whole, and the pretreatment includes fillet transition treatment, and the section changes through the fillet transition.

[0041] Example results: appearance: crack rate ≤ 0.5%; hardness: in line with the pattern; depth of hardened layer: in line with the pattern and enterprise standard;

[0042] Metallographic structure: in accordance with GB / T13320, tempered sorbite (+ ferrite) 1-4 grade; deformation, decarburization: does not affect subsequent machining, conforms to the pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com