Device capable of increasing laying quality of external wall insulation boards and construction method

An external wall thermal insulation board, thermal insulation board technology, applied in thermal insulation, walls, building components and other directions, can solve the problems of damage to the decorative layer, long prefabrication period, and high requirements for lifting and hoisting, and achieves the guarantee of cross-sectional size and improved operation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below:

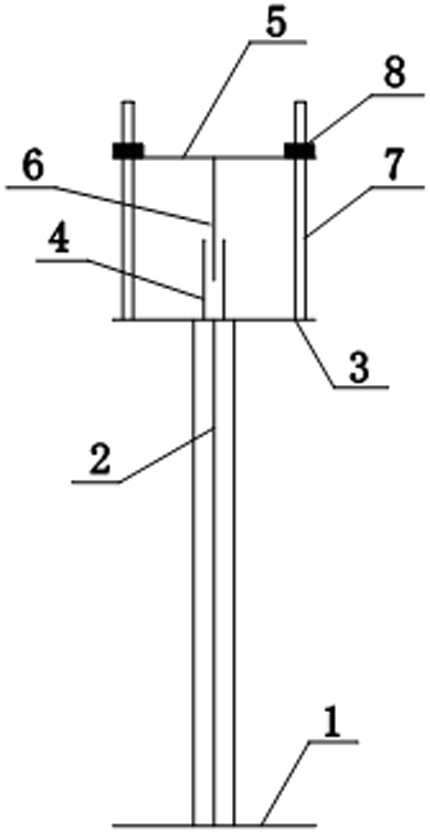

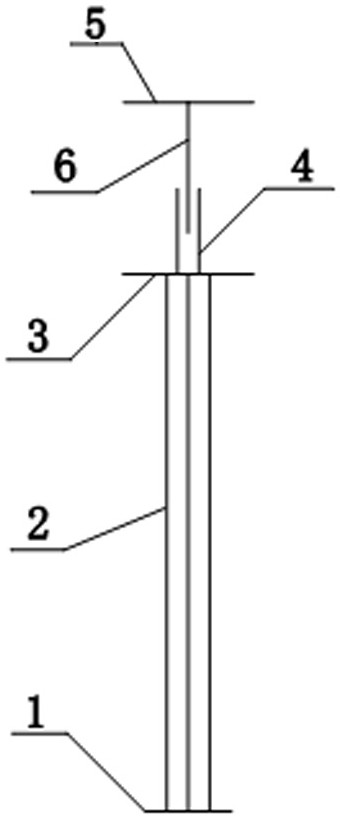

[0033] A device that can improve the laying quality of external wall insulation boards, which uses welding or integral processing to connect the cross-shaped stiffeners 2 on the inner wall support board 1, and connects the cross-shaped stiffeners 2 to the inner baffle of the insulation board by welding 3. The connecting rod conduit 4 is connected by welding on the inner baffle 3 of the insulation board, and the connecting rod 6 welded to the outer baffle 5 of the insulation board is inserted into the connecting rod conduit 4; the connecting rod conduit 4 or connecting rod 6 is used as the In the center, the two sides of the inner baffle plate 3 of the insulation board are welded or threaded to connect the adjustment screw 7, and the adjustment screw 7 is threaded to connect the outer baffle plate 5 of the insulation board. Nuts 8 are installed; the distance between the inner baffle 3 of the insulation board and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com