Prestressed support friction damping assembled steel structure system and design method thereof

A design method and prestressing technology, which is applied in the direction of earthquake resistance, calculation, building components, etc., can solve the problems of many construction nodes, poor seismic resistance of frame structures, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

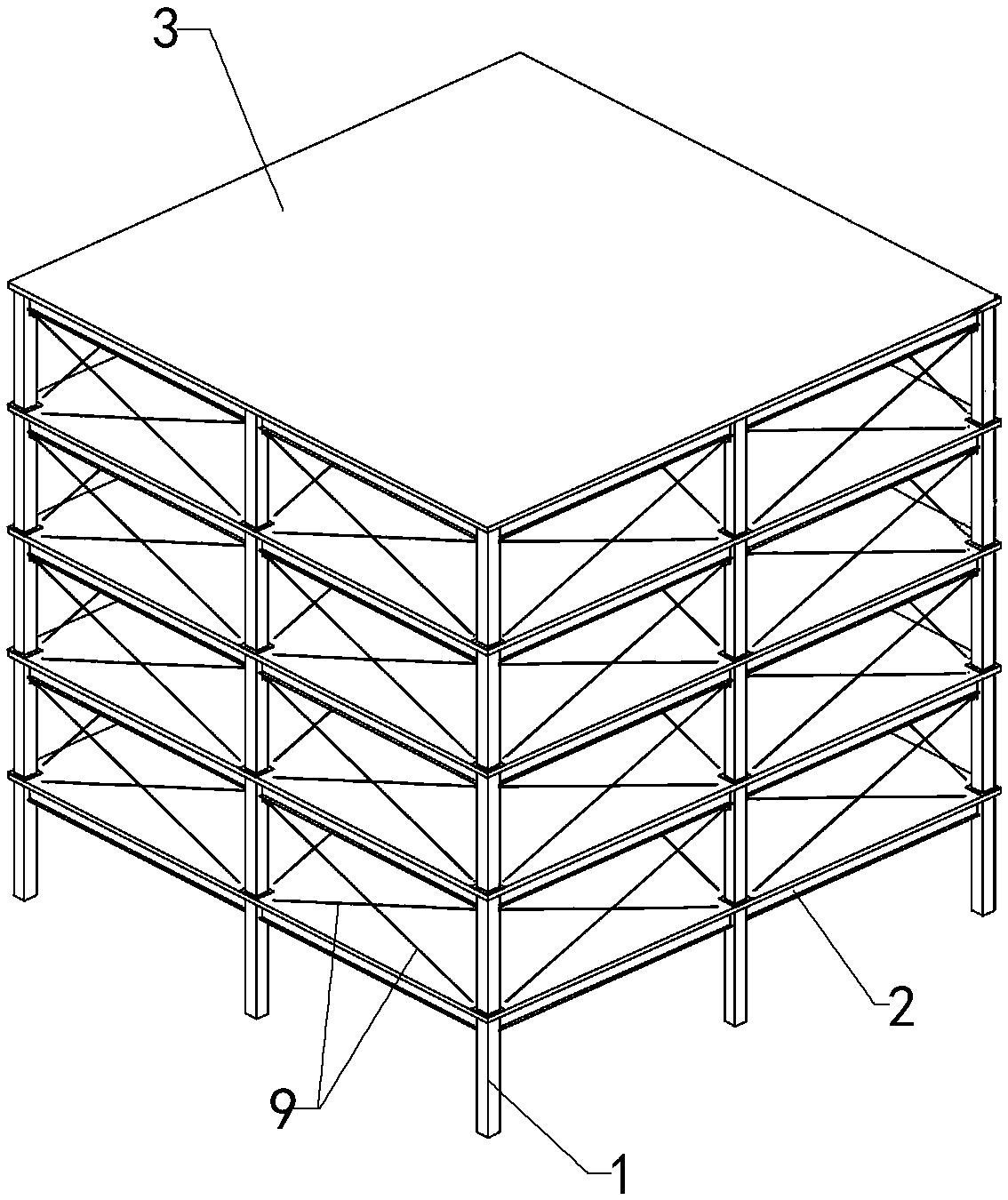

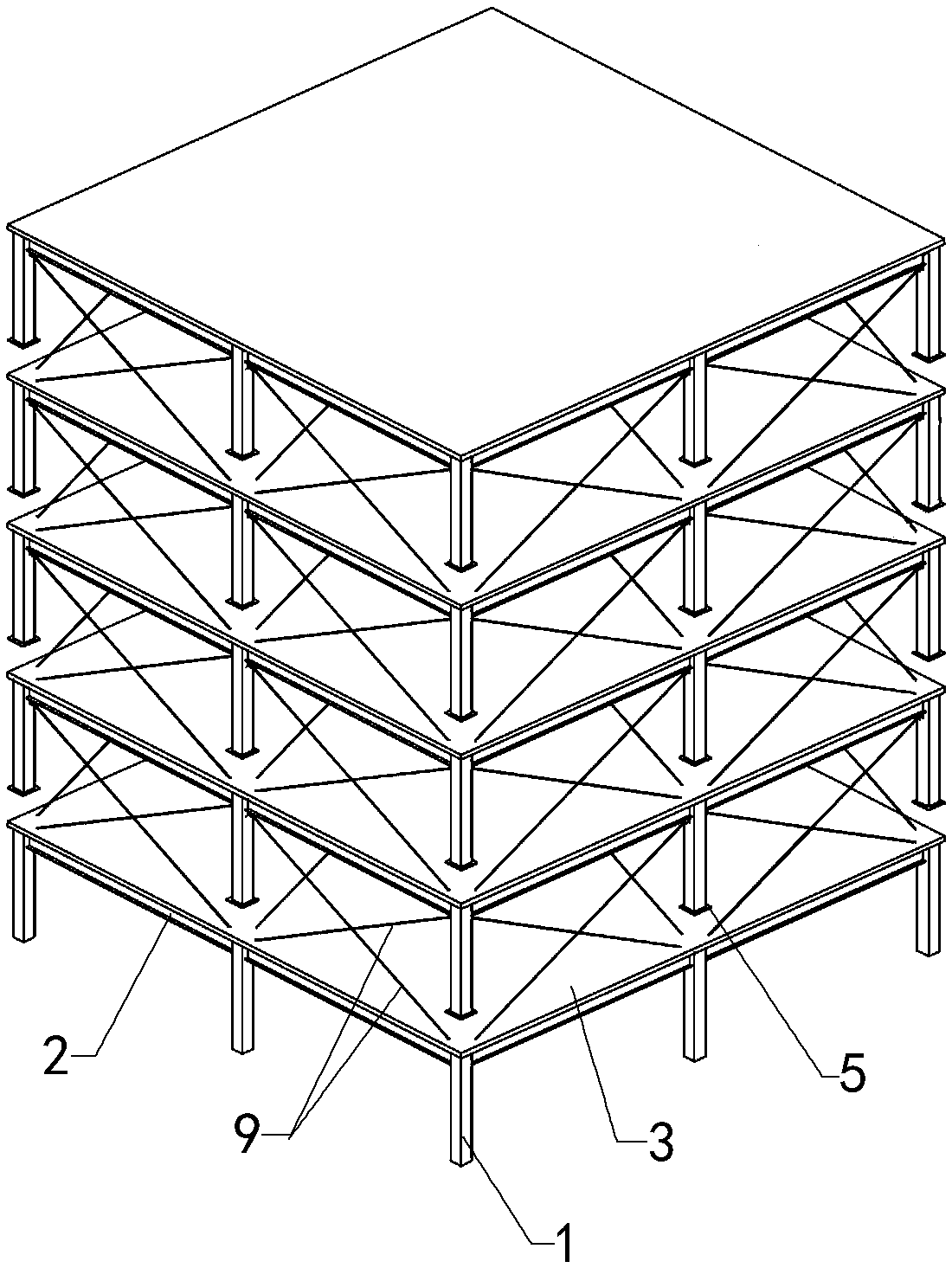

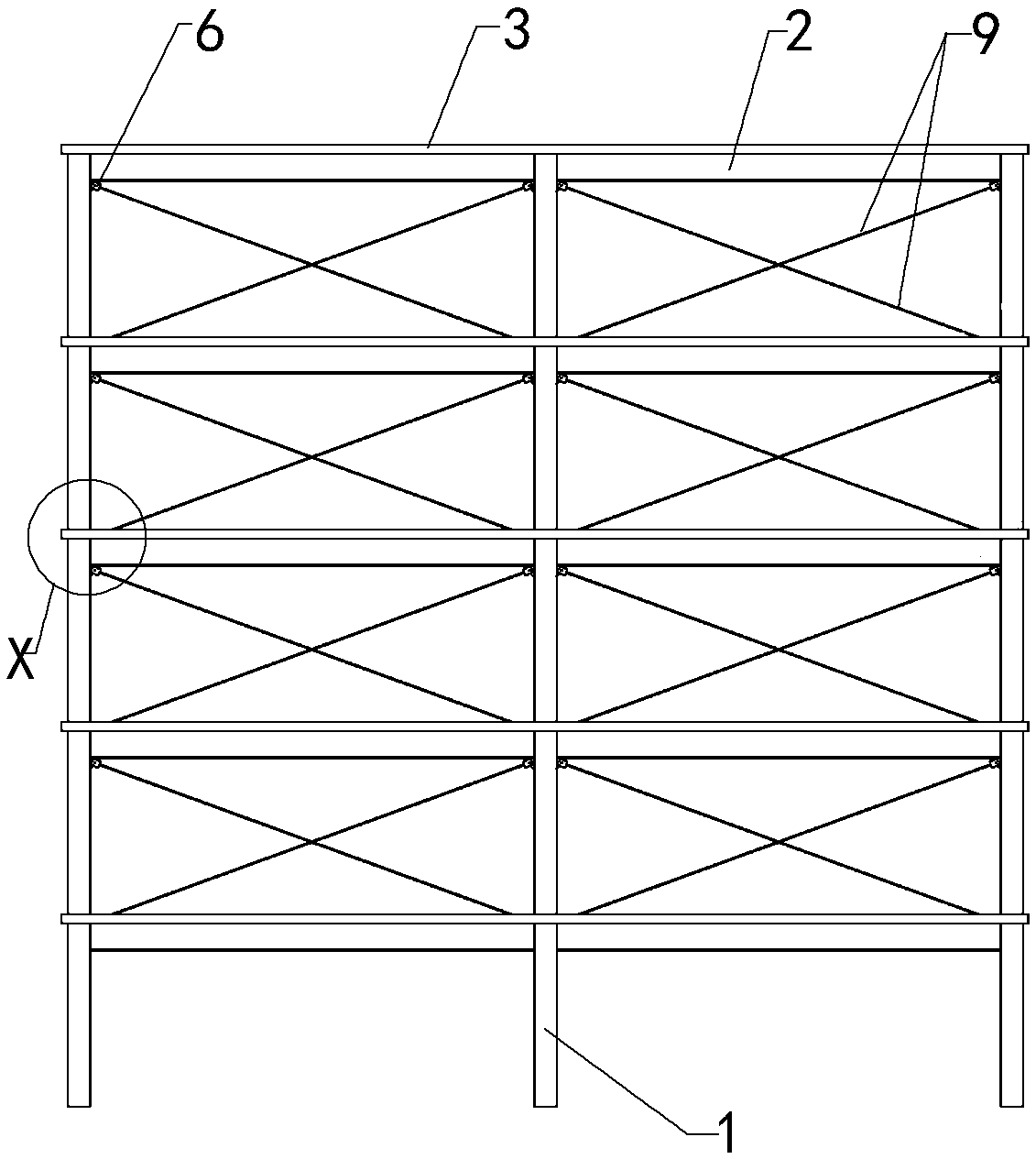

[0116] Such as Figure 1 to Figure 5 As shown, a prestressed support friction damping assembled steel structure system of the present invention is formed by stacking layer frame structures up and down, and adjacent layer frame structures are connected by high-strength cables 9; between the upper and lower adjacent layer frame structures The steel column 1 in between is disconnected at the connection with the lower floor 3, and is connected by self-friction.

[0117] Each floor frame structure includes steel columns 1, steel beams 2 and floor slabs 3. The steel columns 1 in each floor frame structure are arranged in a rectangular shape, the distance between adjacent steel columns 1 is 6-10m, and the steel beams 2 are arranged along the horizontal and longitudinally arranged, and the two ends are respectively fixedly connected with the tops of two adjacent steel columns 1 . The top of the steel column 1 is provided with an upper flange plate 4, which is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com