Chassis of automatic container guiding vehicle

A technology of automatic guided vehicles and containers, which is applied in the direction of motor vehicles, power plants, vehicle parts, etc., can solve the problems of large structural size, high cost of structural size, complex structure, etc., and achieve coordinated steering, improved mobility, and reduced Effect of small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

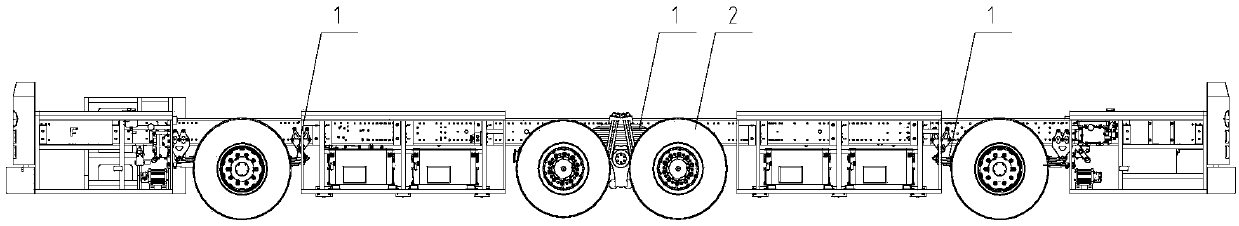

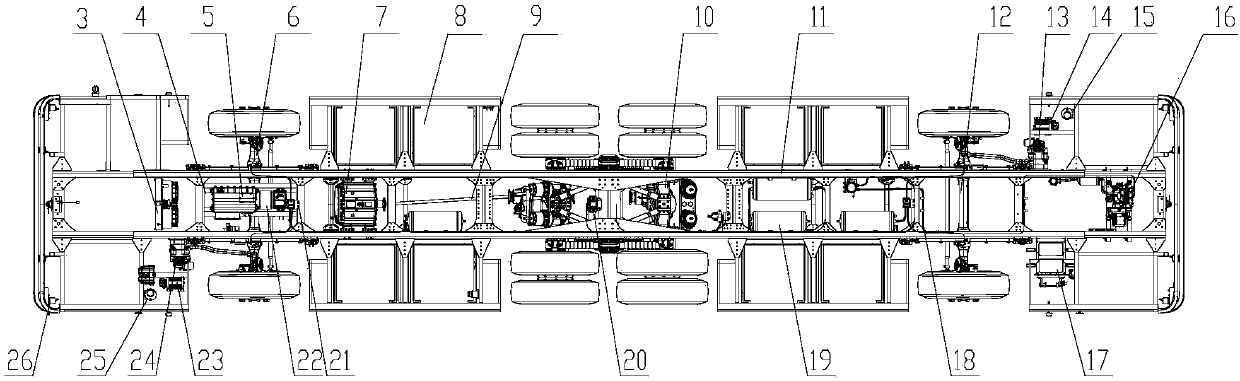

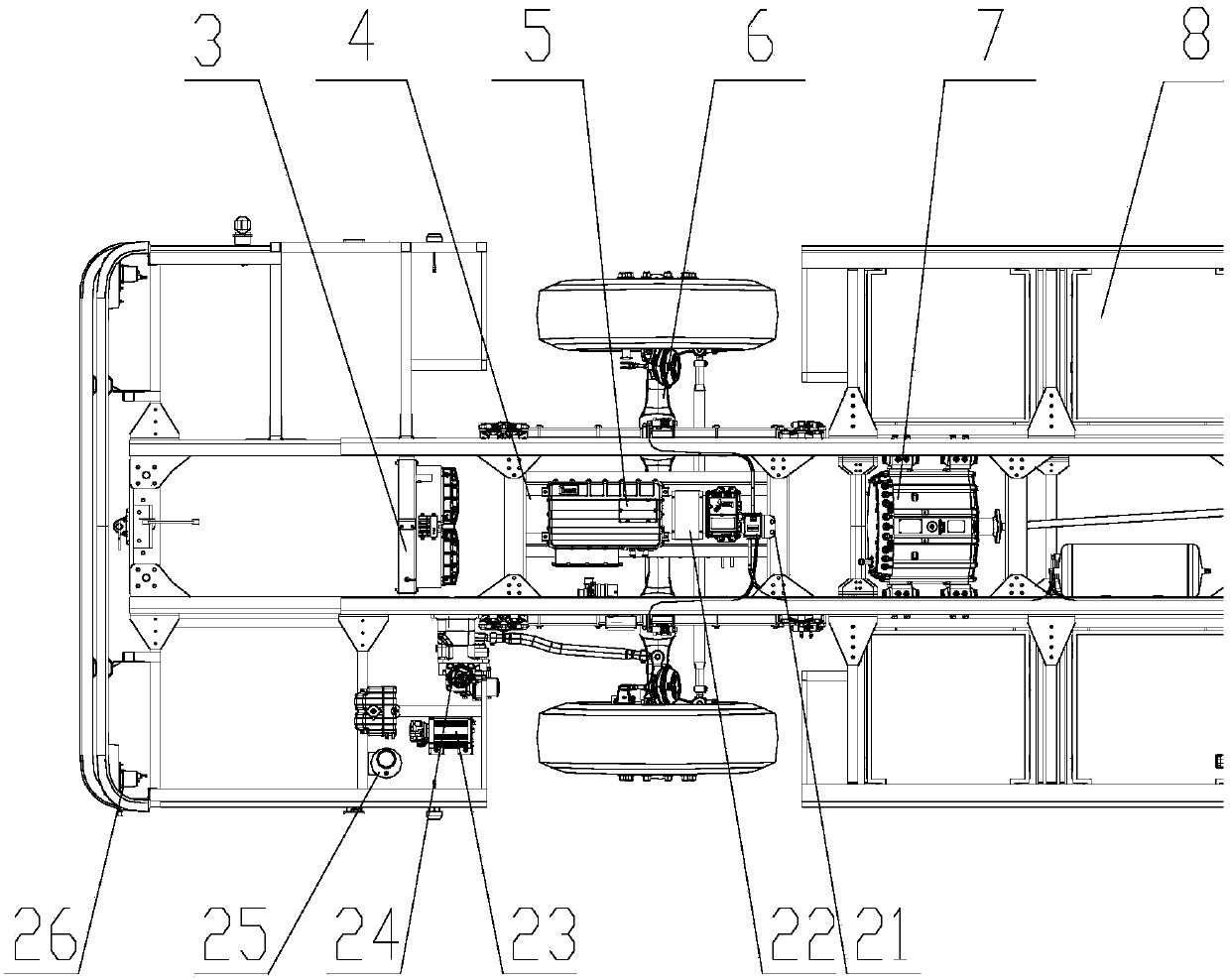

[0038] Such as figure 1 and figure 2 As shown, the present invention provides a container automatic guided vehicle chassis. The chassis of the present invention adopts an 8×4 chassis drive form, that is, the chassis includes four shafts in total, two of which are drive shafts, and the other two are drive shafts. The root is a steering shaft; the two steering shafts in the chassis are respectively a front steering shaft 6 and a rear steering shaft 12, and the front steering shaft 6 and the rear steering shaft 12 are symmetrically arranged front and rear relative to the center of the vehicle; The two drive shafts are two parallel drive axles arranged in the middle of the vehicle, and the two drive axles form the drive axle group 10 .

[0039] Such as Figure 3a As shown, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com