Light aviation bearing rod piece and producing method thereof

A technology of load-bearing rods and load-bearing components, applied in the direction of slender elements, building elements, etc., can solve the problems of insufficient rigidity, heavy weight of components, high cost, etc., and achieve low transverse shear stress, super rigidity and Strength, the effect that the manufacturing method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

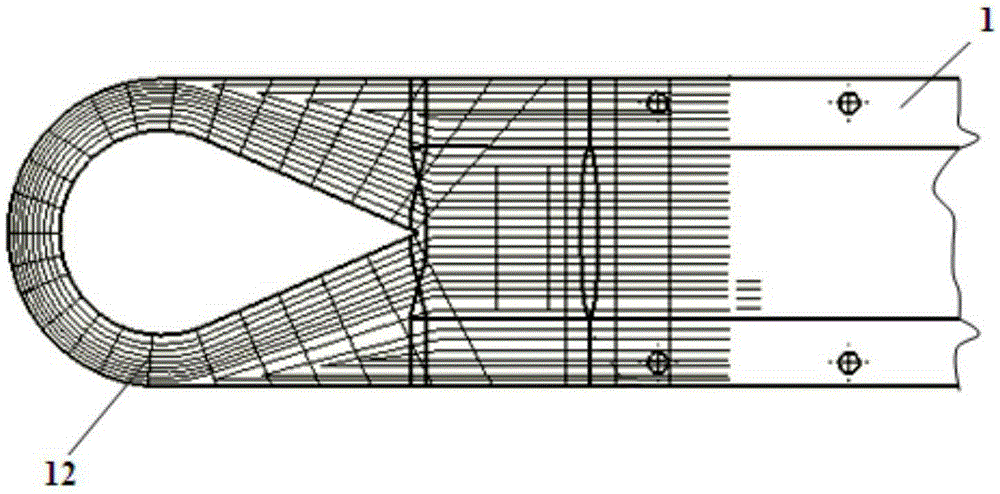

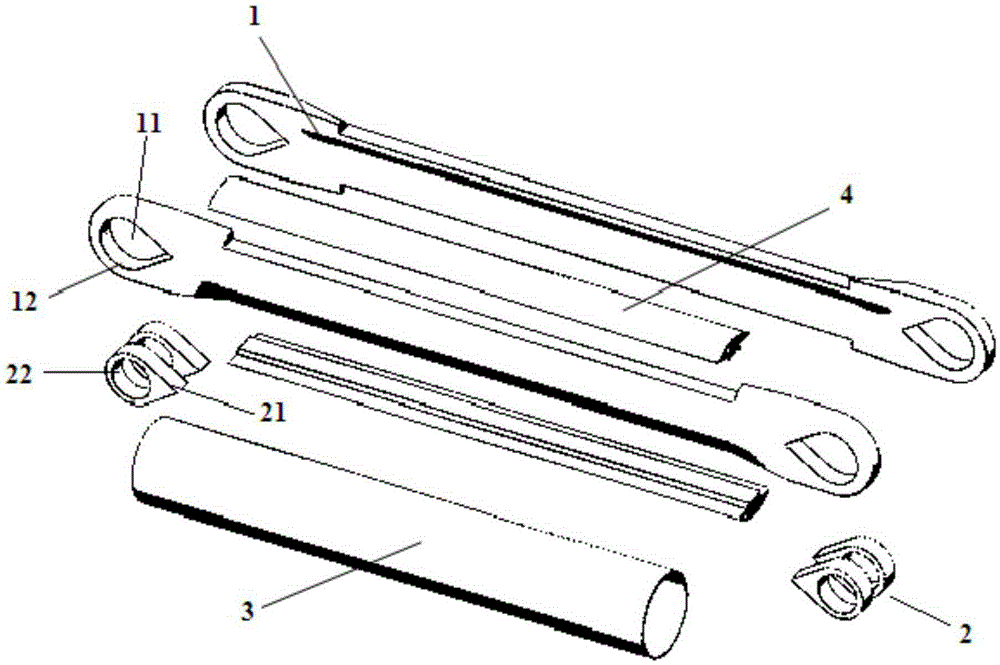

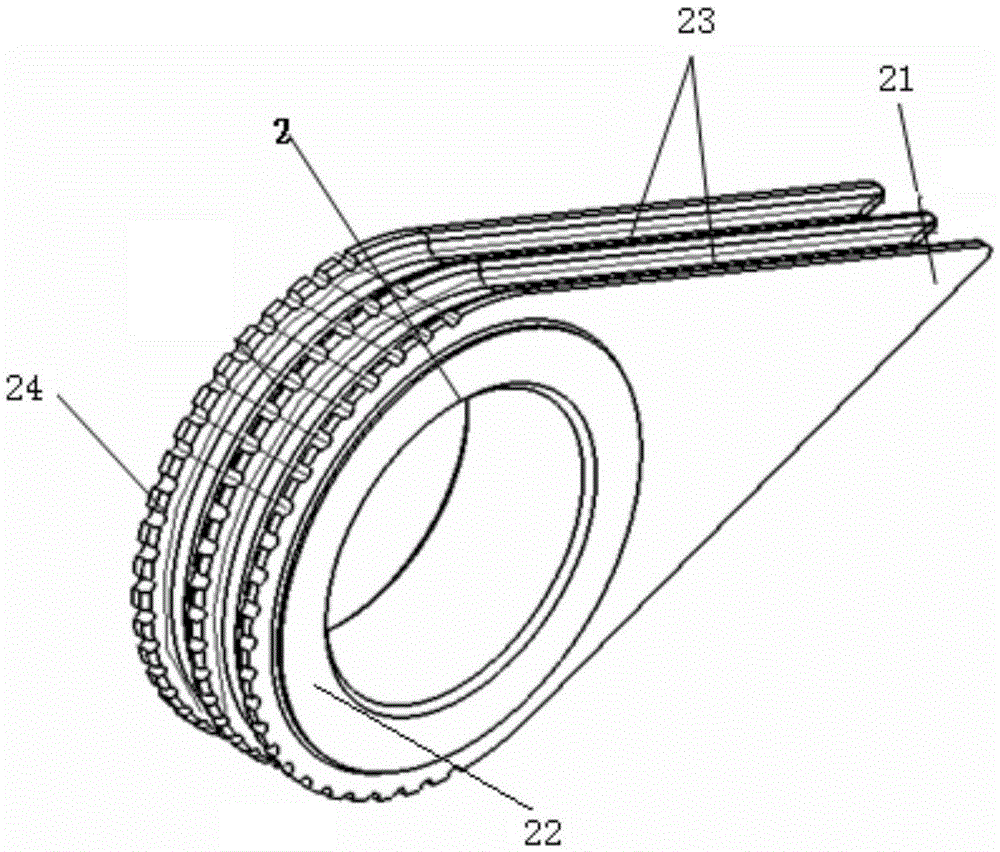

[0039] Such as Figure 1-2 As shown, an aviation light-weight load-bearing rod, including two load-bearing members 1, two inner liners 4, metal bushings 2 and tubular covering layers 3, the two sides of the load-bearing member 1 are respectively embedded in two oppositely arranged In the inner liner 4 of the inner liner 4, a circular tubular tie rod structure is formed, and the tubular covering layer 3 is wrapped on the outside of the load-bearing member 1 and the inner liner 4, and the two ends of the load-bearing member 1 are respectively provided with ear parts 12, and the ear parts 12 A drop-shaped through-hole 11 is provided on the top, and the metal bushing 2 is arranged in the through-hole 11. The outer surface of the metal bushing 2 is provided with a plurality of annular longitudinal grooves 23 longitudinally, and a plurality of ring-shaped longitudinal grooves 23 are arranged horizontally along the circumference of the circular through-hole. Transverse grooves 24 equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com