Preparation method of water-resistant, oil-resistant and anti-falling bamboo fiber environment-friendly meal box

A technology of anti-dropping and bamboo fiber, which is applied in the field of bamboo processing, can solve the problems of fiber agglomeration, unstable physical properties, poor temperature and oil resistance, etc., and achieve the effects of excellent flexibility, alleviating environmental pressure, and rich resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

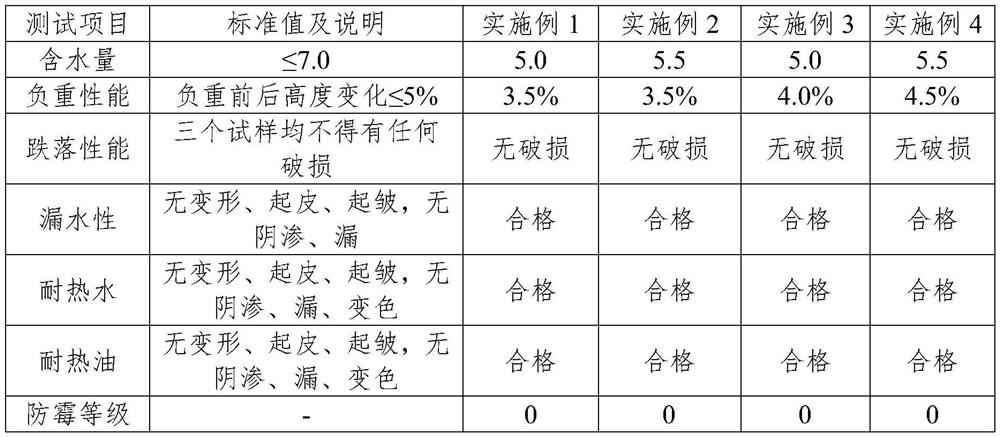

Examples

Embodiment 1

[0035] The preparation method of the water-resistant, oil-resistant and drop-resistant bamboo fiber environmental protection lunch box of the present embodiment, the method is:

[0036] S1, the preparation of thin bamboo veneer: with the 4-year-old round bamboo, be cut into the bamboo tube section that length is 2m, after described bamboo tube section is processed into bamboo bundle fiber, process again, obtain thickness after final drying be 0.10mm, water content ≤8% thin bamboo veneer; the round bamboo is Moso bamboo;

[0037] The specific process of processing the bamboo tube section into thin bamboo veneers after being processed into bamboo bundle fibers is as follows:

[0038]S101, the bamboo tube sections are sequentially split into bamboo pieces, and the bamboo joints are removed to form bamboo strips. After scraping off the bamboo green and bamboo yellow, use 6 sets of symmetrical pressing rollers to mechanically roll and broom to form bamboo bundle fibers. The bundle...

Embodiment 2

[0051] The preparation method of the water-resistant, oil-resistant and drop-resistant bamboo fiber environmental protection lunch box of the present embodiment, the method is:

[0052] S1, the preparation of thin bamboo veneer: the 3-year-old round bamboo is cut into a bamboo tube section with a length of 1m, and the bamboo tube section is processed into bamboo bundle fibers before processing or the bamboo tube section is rotary cut, and finally dried A thin bamboo veneer with a thickness of 0.30 mm and a moisture content of ≤ 8% is obtained; the round bamboo is Cizhu;

[0053] The specific process of processing the bamboo tube section into thin bamboo veneers after being processed into bamboo bundle fibers is as follows:

[0054] S101. Sequentially split the bamboo tube section into pieces, remove the bamboo joints to form bamboo strips, scrape off the bamboo green and bamboo yellow, and use 5 sets of symmetrical pressing rollers to mechanically roll and broom to form bamboo...

Embodiment 3

[0066] The preparation method of the water-resistant, oil-resistant and drop-resistant bamboo fiber environmental protection lunch box of the present embodiment, the method is:

[0067] S1, preparation of thin bamboo veneer: 4-year-old round bamboo is cut into a bamboo tube section with a length of 1.5m, and the bamboo tube section is processed into bamboo bundle fibers and then processed and finally dried to obtain a thickness of 0.2mm and a moisture content of 0.2mm. ≤8% thin bamboo veneer; the round bamboo is green bamboo;

[0068] The specific process of processing the bamboo tube section into thin bamboo veneers after being processed into bamboo bundle fibers is as follows:

[0069] S101, the bamboo tube sections are sequentially split into bamboo pieces, and the bamboo joints are removed to form bamboo strips. After scraping off the bamboo green and bamboo yellow, use 3 sets of symmetrical pressing rollers to mechanically roll and broom to form bamboo bundle fibers, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com