Electrodeless composite microporous membrane for polymer diaphragm

A microporous membrane and polymer technology, applied in the field of non-polar composite microporous membranes, can solve the problems of inability to meet application requirements and poor tensile strength of microporous membranes, achieve good electrophilic liquid and heat dissipation performance, wide application, process The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

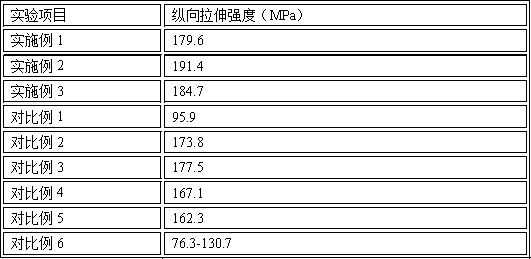

Examples

preparation example Construction

[0025] In an embodiment, the non-polar composite microporous membrane used for the polymer diaphragm includes the following raw materials in parts by mass: 120-160 parts of polypropylene, 1.5-2.6 parts of nucleating agent, 7-11 parts of three Trimethylol propyl methacrylate, 0.5-1.2 parts of styrene phenol polyoxyethylene ether ammonium sulfate, 5-8 parts of sodium trimethylsiliconate, and 2-4 parts of magnesium ethylate, the preparation method thereof comprises the following steps:

[0026] (1) 120-160 parts by mass of polypropylene, 1.5-2.6 parts of nucleating agent, 7-11 parts of trimethylolpropyl trimethacrylate, 0.5-1.2 parts of styrene phenol polyoxyethylene ether After mixing ammonium sulfate, 5-8 parts of sodium trimethylsiliconate, and 2-4 parts of magnesium ethoxide, stir for 18-25 minutes at a microwave power of 100-200W, a temperature of 45-52°C, and a speed of 200-300r / min , to obtain a mixed material; the nucleating agent includes one or more of a compound of a m...

Embodiment 1

[0031] A kind of electrodeless composite microporous membrane that is used for macromolecular diaphragm, with mass part as unit, comprises following raw material: 123 parts of polypropylene (the product of F401 type that Sinopec Yangzi Petrochemical Co., Ltd. provides, isotacticity is 98%) , 1.7 parts of nucleating agent (DX-Z3C model product provided by Dongguan Dingxin Plastic Raw Material Co., Ltd.), 7 parts of trimethylolpropyl trimethacrylate, 0.6 part of styrene phenol polyoxyethylene ether ammonium sulfate, 5 parts of sodium trimethylsiliconate, 2 parts of magnesium ethylate, and their preparation method comprises the following steps:

[0032] (1) 123 parts by mass of polypropylene (F401 type product provided by Sinopec Yangzi Petrochemical Co., Ltd., with an isotacticity of 98%), 1.7 parts of nucleating agent (Dongguan Dingxin Plastic Raw Materials Co., Ltd. DX-Z3C model product), 7 parts of trimethylolpropyl trimethacrylate, 0.6 parts of styrene phenol polyoxyethylene...

Embodiment 2

[0036] A kind of electrodeless composite microporous membrane that is used for macromolecular diaphragm, in mass part, comprises following raw material: 142 parts of polypropylene (the product of F401 type that Sinopec Yangzi Petrochemical Co., Ltd. provides, isotacticity is 98%) , 2 parts of nucleating agent (DX-Z3C model product provided by Dongguan Dingxin Plastic Raw Material Co., Ltd.), 10 parts of trimethylolpropyl trimethacrylate, 1 part of styrene phenol polyoxyethylene ether ammonium sulfate, 7 parts of sodium trimethylsilanolate, 3 parts of magnesium ethylate, and their preparation method comprises the following steps:

[0037] (1) 142 parts by mass of polypropylene (F401 type product provided by Sinopec Yangzi Petrochemical Co., Ltd., with an isotacticity of 98%), 2 parts of nucleating agent (Dongguan Dingxin Plastic Raw Materials Co., Ltd. Provided DX-Z3C model), 10 parts of trimethylolpropyl trimethacrylate, 1 part of styrene phenol polyoxyethylene ether ammonium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com