A kind of ultra-thin ultra-mirror polypropylene aluminized substrate film preparation method

A technology for film preparation and polypropylene materials, which is applied in the field of film packaging, can solve the problems of low surface brightness, poor effect of aluminized film, and low production efficiency, and achieve the effects of improved optical performance, high production efficiency, and excellent thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment adopts a single-layer material structure, and 100% Nordic chemical copolymerized polypropylene resin RB707CF is selected as the high melt strength polypropylene material, wherein the Vicat softening point of RB707CF is 125°C.

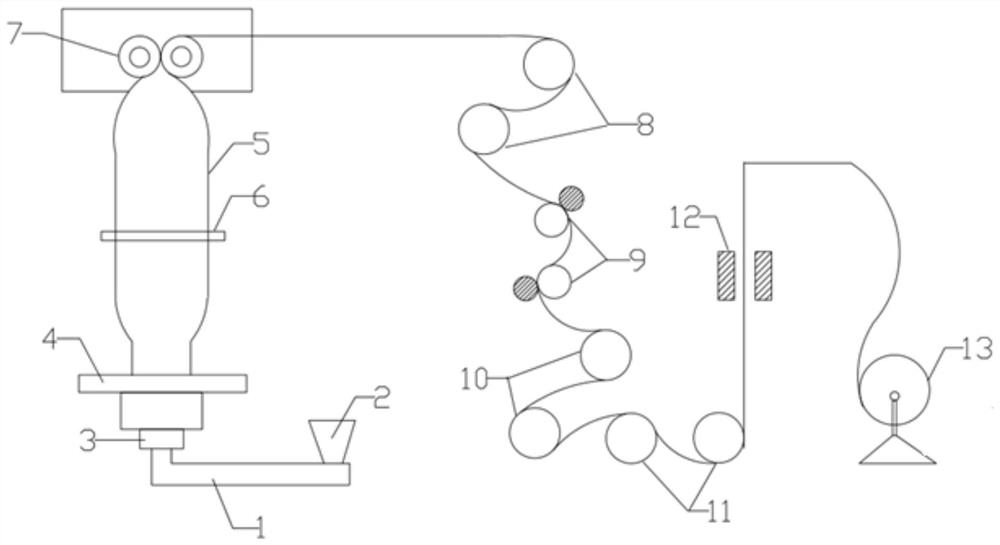

[0032] like figure 1 As shown, the specific preparation method is: add RB707CF into the silo 1, heat and melt it through the extruder 2, and then extrude it from the die head 3. The blow-up ratio is 2.3, and the temperature of the molten material is adjusted and controlled between 210°C and 230°C. , the initial thickness of the film is set to 48 microns, and the film bubble 5 is blown into the film bubble 5 by the automatic wind ring 4 and the thickness is adjusted. The thickness measurement module 6 performs a thickness measurement once, and then the traction roller mechanism 7 performs clamping and traction, and the traction speed is 50 m / min. Use the stretching roller 9 to carry out online longitudinal stretching at a temperatu...

Embodiment 2

[0034]This embodiment adopts a three-layer material structure, and the structural composition is A / B / C, wherein the thickness ratio of the three layers of A, B, and C is 1:2:1, A and B are the surface layers, and the selected materials are all 100% High melt strength Borealis polypropylene copolymer RB707CF, its Vicat softening point is 125°C; C is the heat-sealing layer, the choice of material for this layer is: 80% Borealis copolymerized polypropylene RB707CF, 19% Exxon Mobil's elastomer Vistamaxx 6102FL and 1% Schulman opening slip masterbatch FSU105E.

[0035] like figure 1 As shown, the specific preparation process is as follows: the above-mentioned A, B, and C three-layer materials are added to the silo 1, heated and melted by the extruder 2, and then extruded from the die head 3. The blow-up ratio is 2.3, and the temperature of the molten material is adjusted. Controlled between 210°C and 230°C, the initial thickness of the film is set to 60 microns, and the film bubbl...

Embodiment 3

[0037] This embodiment adopts a five-layer material structure, and the structure is composed of A / B / C / D / E (the thickness ratio of each layer is 20%), A and E are surface layers, and the selected materials are all 100% high melt strength The Nordic chemical copolymerized polypropylene RB707CF, the Vicat softening point is 125 °C; the materials of the B and D layers are: 50% of the Nordic chemical copolymerized polypropylene RB707CF and 50% of the Dow chemical metallocene material DOW INNATE ST50; the material of the C layer For: 100% DOW INNATE ST50 metallocene material from Dow Chemical.

[0038] like figure 1 As shown, the specific preparation process is as follows: Add the materials of the above five layers of A, B, C, D, and E into the silo 1, heat and melt them through the extruder 2, and then extrude them from the die head 3 with a blow-up ratio of 2.3, and melt The temperature of the material is adjusted and controlled between 210°C and 230°C, the initial thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com