Film forming equipment

A film-forming equipment and film-forming chamber technology, which is applied in ion implantation plating, coating, metal material coating process, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

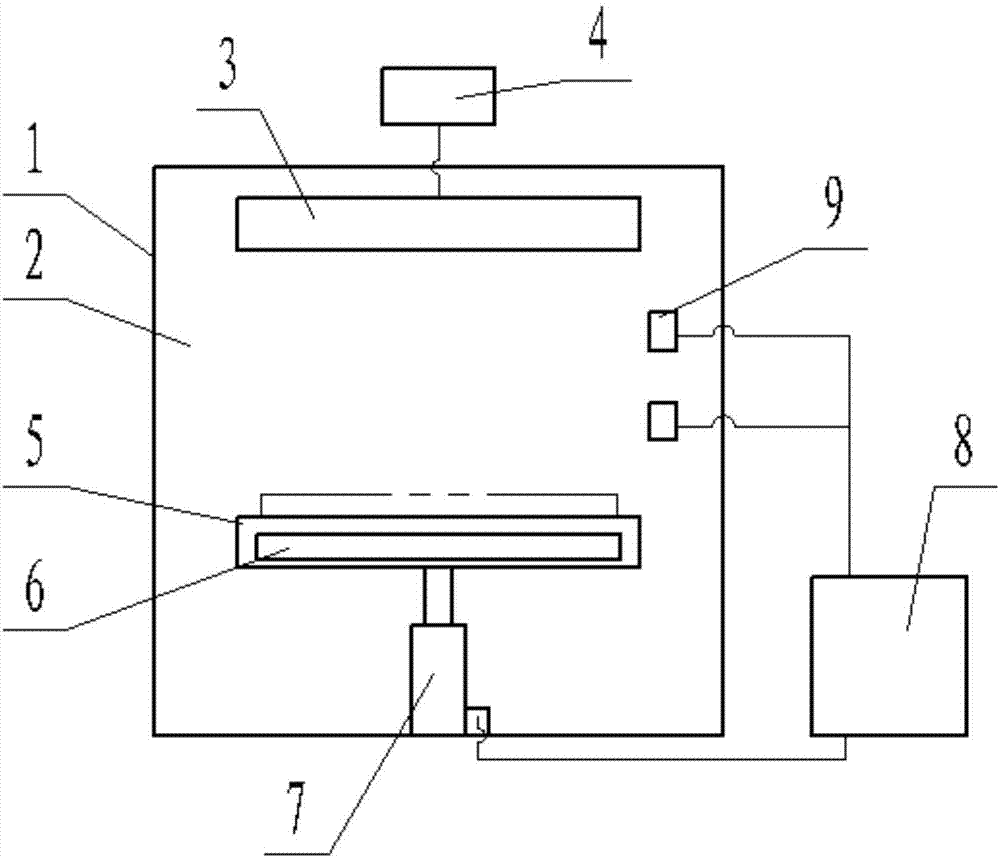

[0024] Embodiment 1: as figure 1 As shown, the present embodiment provides a film forming device, which includes a housing 1 , and the inside of the housing 1 is a film forming chamber 2 . The upper part of the film forming chamber 2 is provided with a target material 3 , the cross section of the target material 3 is preferably larger than the cross section of the workpiece, so as to improve the uniformity of the film layer. The target 3 is connected with a sputtering source 4, and the sputtering source 4 can be selected as a microwave generator, a radio frequency generator or a DC power supply, and different types of sputtering sources 4 need to be selected according to different film-forming methods. The lower part of the film forming chamber 2 is provided with a workbench 5 for placing workpieces, and inside the workbench 5 is provided with a heating device 6, which is preferably a resistance heater. The workbench 5 is driven to move up and down by an electric push rod 7 ,...

Embodiment 2

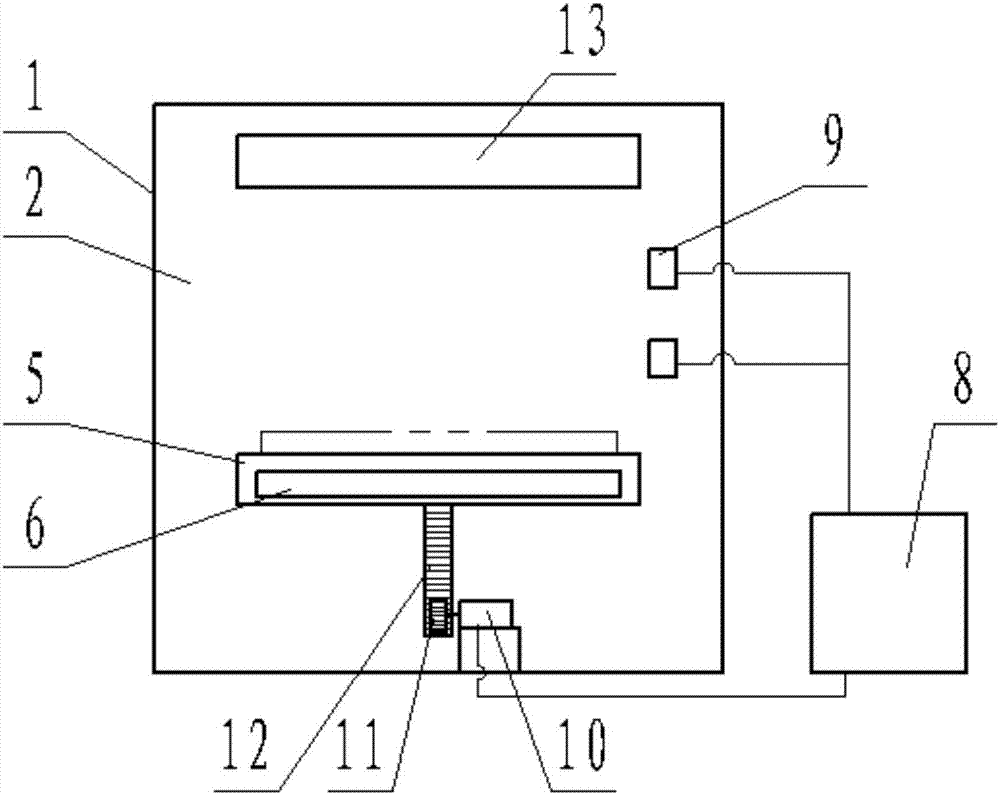

[0028] Embodiment 2: as figure 2 As shown, the working process and technical effect of this embodiment and embodiment 1 are the same, the difference between this embodiment and embodiment 1 is: the top of the film forming chamber is provided with an evaporation source 13, and the evaporation source 13 adopts thermal evaporation or electron beam evaporation The workbench 5 is driven to move up and down by a linear motion mechanism, the linear motion mechanism includes a servo motor 10, a drive gear 11 and a rack 12, the servo motor 10 is arranged on the housing 1, and the drive gear 11 is arranged on the drive shaft of the servo motor 10 Above, the rack 12 is arranged on the workbench 5, and the driving gear 11 is meshed with the rack 12.

[0029] It should be noted that conventional film forming equipment only controls the thickness and uniformity of the film deposited on the workpiece by controlling the pressure, gas, temperature and time in the film forming chamber 2 . How...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com