Assembling functional restorable steel skeleton concrete combined column and installation method

A steel skeleton and assembled technology, applied in the direction of columns, pillars, pier columns, etc., can solve the problems of low degree of assembly, insufficient integrity, difficult to repair, etc., to achieve improved seismic performance, excellent energy absorption capacity, and convenient repair and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

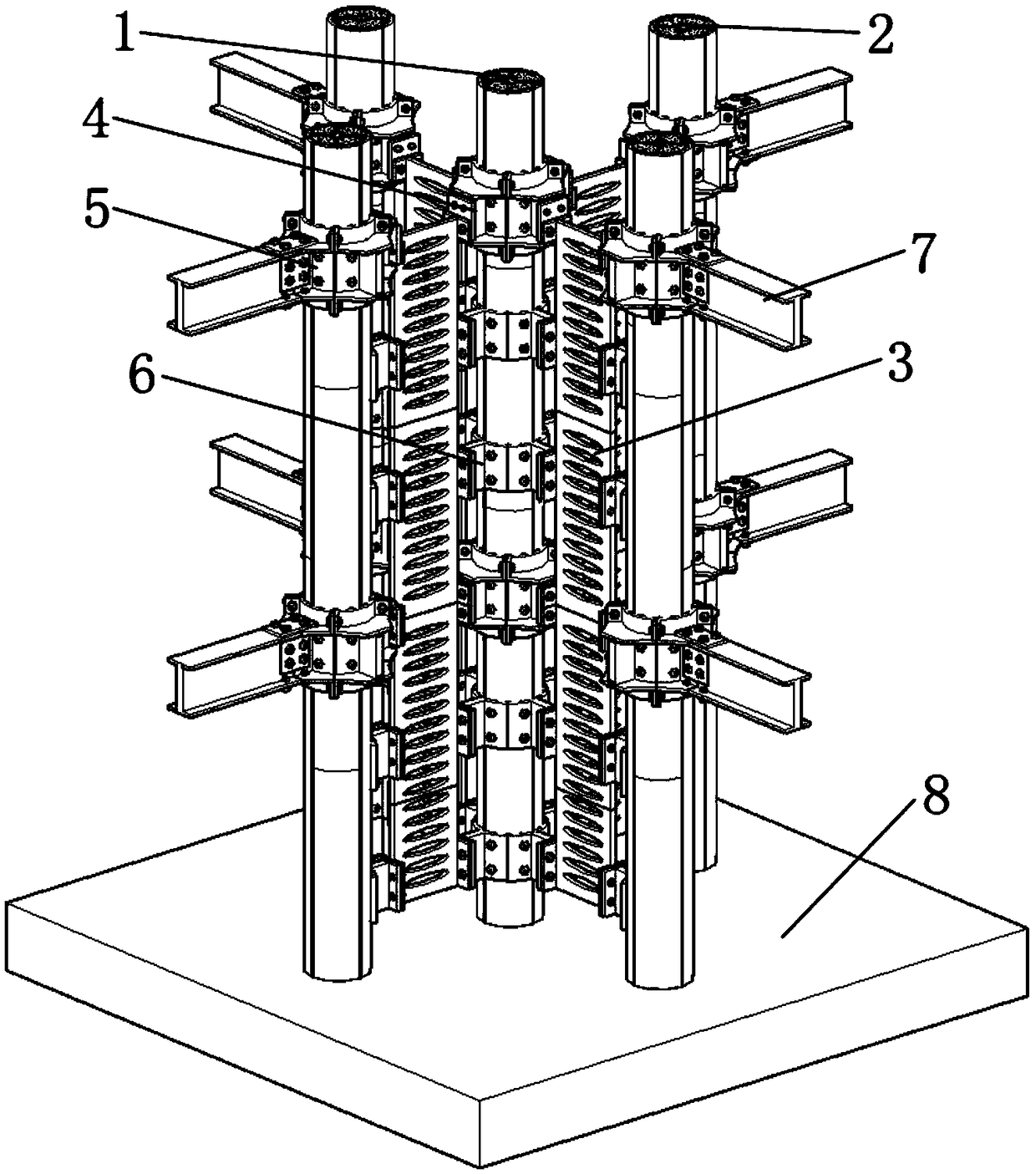

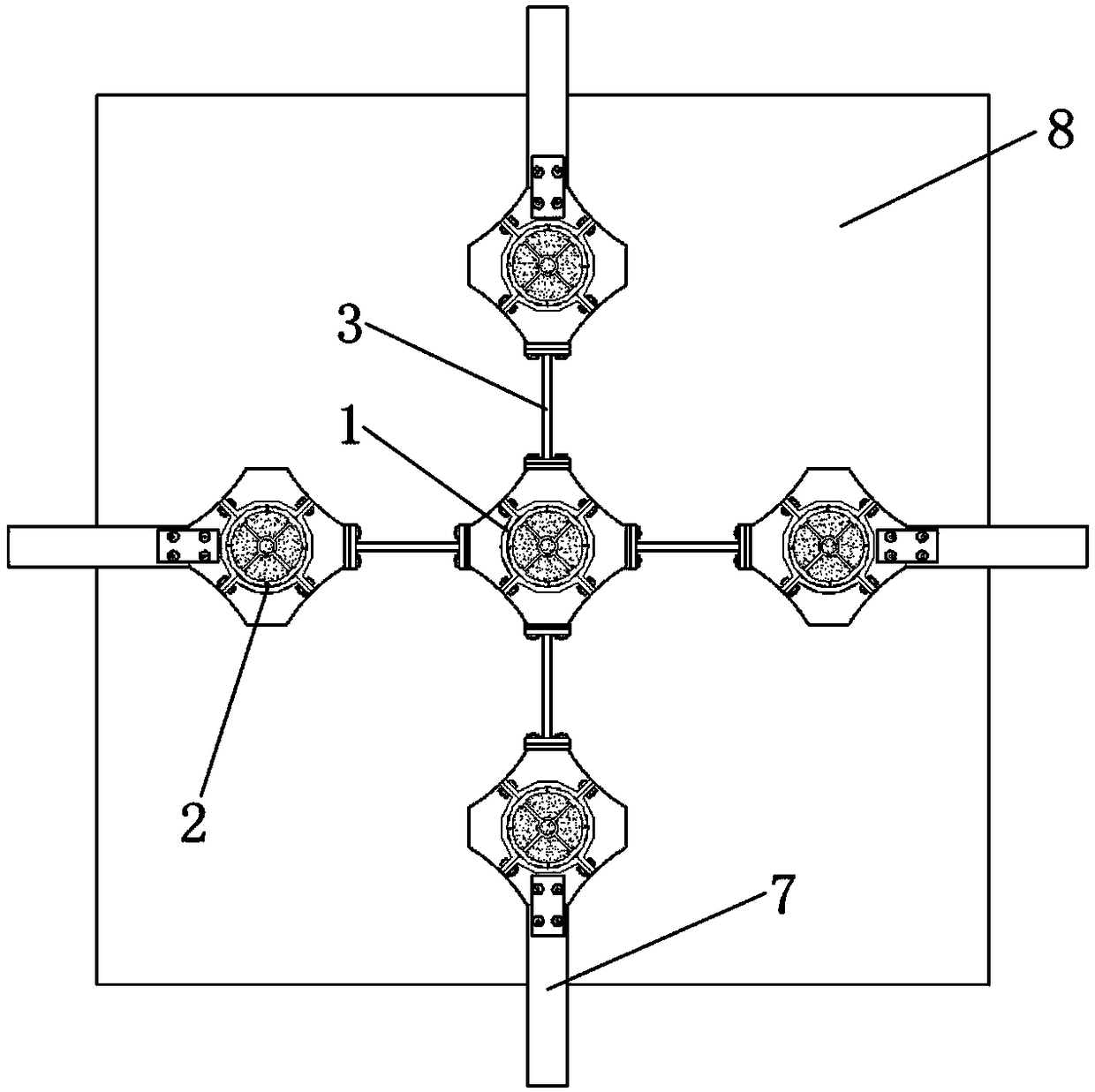

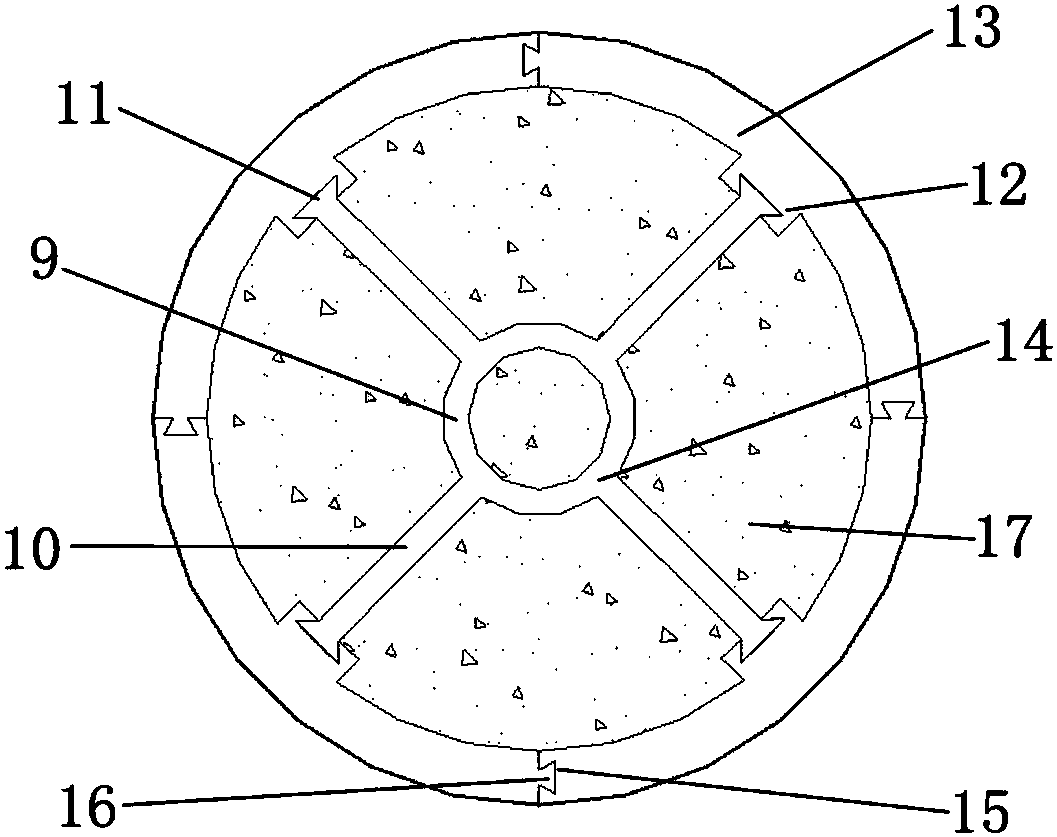

[0060] like Figure 1-11 As shown, a prefabricated function recoverable steel frame concrete composite column is located on the foundation 8, including 1 set of steel pipe main columns 1, 4 sets of steel pipe subordinate columns 2, 16 main and slave columns energy-dissipating connecting bridges 3 and 10 full Assembled connection assembly; the fully assembled multifunctional connection assembly can be used to connect columns and bridge frames, and can also be used to connect columns and H-shaped steel beams 7 . The fully assembled connection assembly includes 4 arc-shaped foot connectors and 4 external reinforcing ring tiles 26, and the central angles are all 90 degrees. The seams between the arc-shaped foot connectors and the seams between the column sheets are staggered from each other. The outer reinforcement ring tiles are assembled into a circular outer reinforcement ring, and the steel pipe column is tightly hooped; the arc-shaped foot connectors include A-shaped arc-sha...

Embodiment 2

[0065] The rectangular connecting feet 18 of the main-slave column energy-dissipating connecting bridge are divided into upper rectangular connecting feet, middle rectangular connecting feet and lower rectangular connecting feet. The middle rectangular connecting feet are located on both sides of the middle part of the energy-dissipating steel plate, and are provided with 4 bolt holes; the lower rectangular connecting feet are located on both sides of the lowermost part of the energy-dissipating steel plate, and are provided with two horizontal bolt holes; the rectangular connection of the arc-shaped foot connecting piece The foot 23 is provided with a bolt hole matching the rectangular connecting foot of the master-slave column energy dissipation connecting bridge.

[0066] The longitudinal lengths of the steel pipe columns are 500mm, 750mm, 1000mm and 1500mm respectively. The purpose is to stagger the four column pieces at different positions in the length direction, on the ...

Embodiment 3

[0069] like Figure 12 As shown, the difference between this embodiment and embodiment 2 is that there is 1 group of main columns forming the combined column, and 2 groups of subordinate columns, and the interval angle between the energy dissipation connecting bridge between the main column and the subordinate column is 60 degrees, there are 2 outrigger beams. All the other are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com