Making method for metal zipper teeth

The technology of a metal zipper and a manufacturing method, which is applied to clothing, fasteners, sliding fastener components, etc., can solve the problems of easy oxidation and corrosion of materials, short service life of zippers, rough appearance, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

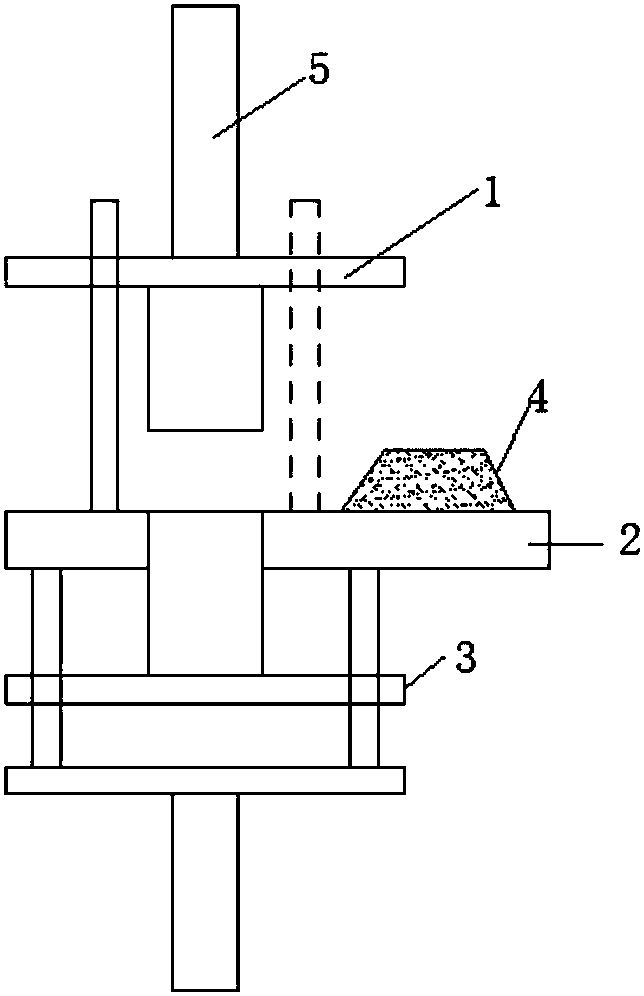

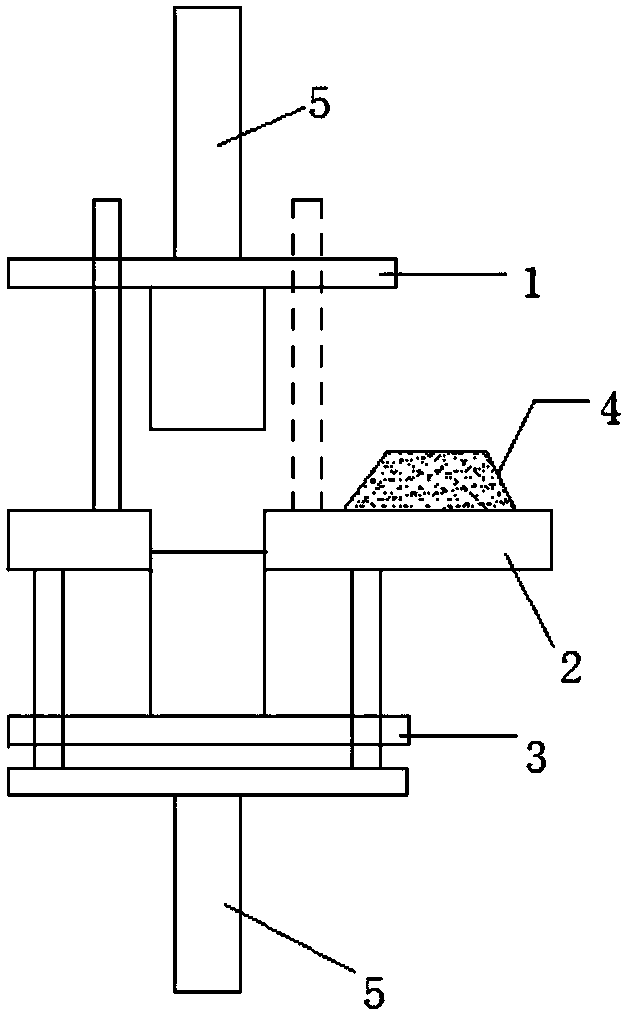

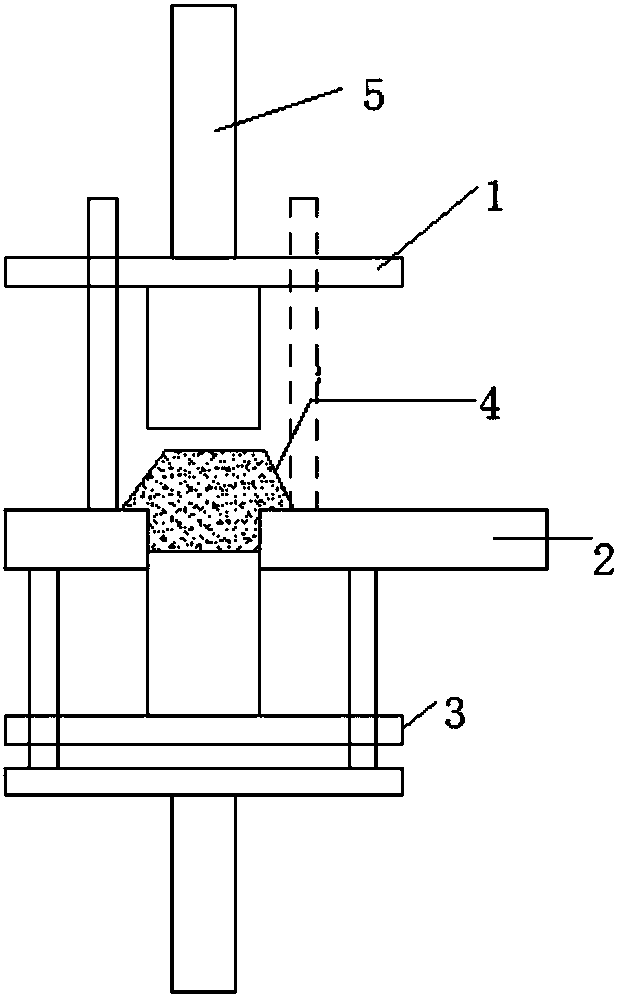

Image

Examples

specific Embodiment 1

[0045] A method for making metal zipper elements includes: S1, selecting copper alloy metal powder as the basic raw material; S2, calculating the required density and pressure, the density calculation formula is density=volume*unit weight; pressure=15t / cm 2 ; Calculate the shrinkage ratio 1:1.06 with reference to the size and raw material characteristics of copper alloy powder, and design the mold of the required chain element shape; S3, press the metal powder through the mold; S4, use the sintering furnace protected by gas or vacuum to The copper metal zipper elements obtained in step S3 are sintered, the sintering temperature ranges from 650°C to 750°C, and the sintering time is 1 to 4 hours; S5, according to the physical characteristics of the copper alloy powder material, select the corresponding grinding equipment and grinding materials for sintering. Polished, S6, gets copper alloy zipper elements.

specific Embodiment 2

[0047] A method for making metal zipper elements includes: S1, selecting stainless steel metal powder as the basic raw material; S2, calculating the required density and pressure, the density calculation formula is density = volume * unit weight; pressure = 15t / cm 2; Calculate the shrinkage ratio 1:1.07 with reference to the size and the characteristics of the stainless steel powder raw material, and design the mold of the required chain element shape; S3, press the metal powder through the mold; S4, use the sintering furnace protected by gas or vacuum to S3 The copper metal zipper elements obtained in the step are sintered, the sintering temperature ranges from 1100°C to 1400°C, and the sintering time is 1 to 4 hours; S5, according to the physical properties of the stainless steel powder material, select the corresponding grinding equipment and grinding materials for polishing, S6, get stainless steel zipper elements.

specific Embodiment 3

[0049] A method for making metal zipper elements includes: S1, selecting titanium alloy metal powder as the basic raw material; S2, calculating the required density and pressure, the density calculation formula is density=volume*unit weight; pressure=15t / cm 2 ; Calculate the shrinkage ratio of 1:1.06 with reference to the size and raw material characteristics of titanium alloy powder, and design the mold of the required chain element shape; S3, press the metal powder through the mold; S4, use the sintering furnace protected by gas or vacuum Sinter the copper metal zipper elements obtained in step S3, the sintering temperature ranges from 1000°C to 1400°C, and the sintering time is 1 to 4 hours; S5, according to the physical properties of the titanium alloy powder material, select the corresponding grinding equipment and grinding materials Carry out polishing, S6, to get titanium alloy zipper elements.

[0050] The present invention also discloses a metal zipper element, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com