Preparing method of polysulfide rubber sealing ring

A technology of polysulfide rubber and liquid polysulfide rubber, which is applied in the field of sealing materials, can solve the problems of shortening the service life of sealing rings, low strength, and poor flame retardancy, so as to avoid flammability, good flame retardancy, and sealing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

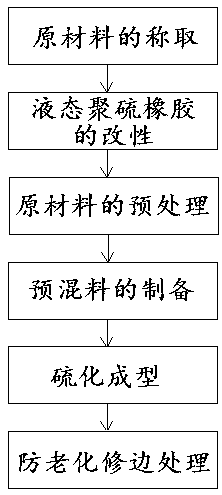

Image

Examples

Embodiment 1

[0038] A preparation method of polysulfide rubber sealing ring, comprising:

[0039] Step 1, weighing raw materials: weighing each raw material component according to the following parts by mass: 50 parts of liquid polysulfide rubber; 3 parts of propionate; 6 parts of epoxy group; 12 parts of bisphenol A epoxy resin; 15 parts of plasticizer; 2 parts of rosin resin; 2 parts of softener; 5 parts of carbon black; 10 parts of mixture of antimony trioxide and flame-retardant graphite; 1 part of manganese dioxide; 5 parts of filler; average particle size of flame-retardant graphite It is 1800 mesh, and the average particle size of antimony trioxide is 1 micron.

[0040] Step 2, modification of liquid polysulfide rubber: under inert gas (nitrogen) conditions, polysulfide rubber is capped and modified with propionate and epoxy groups, and then mixed with bisphenol A epoxy resin to obtain modified polysulfide rubber. sulfur rubber;

[0041] Step 3, pretreatment of raw materials: Afte...

Embodiment 2

[0046] A preparation method of polysulfide rubber sealing ring, comprising:

[0047] Step 1, weighing of raw materials: weighing of each raw material component according to the following parts by mass: 50 parts of liquid polysulfide rubber; 4 parts of propionate; 6 parts of epoxy group; 10 parts of bisphenol A epoxy resin; 15 parts of plasticizer; 10 parts of terpene resin; 10 parts of softener; 15 parts of carbon black; 10 parts of a mixture of antimony trioxide and flame-retardant graphite; 10 parts of lead dioxide; 20 parts of filler; The particle size is 3000 mesh, and the average particle size of antimony trioxide is 0.3 micron.

[0048] Step 2, modification of liquid polysulfide rubber: under inert gas (nitrogen) conditions, polysulfide rubber is capped and modified with propionate and epoxy groups, and then mixed with bisphenol A epoxy resin to obtain modified polysulfide rubber. sulfur rubber;

[0049] Step 3, pretreatment of raw materials: After adding a plasticizer...

Embodiment 3

[0054] A preparation method of polysulfide rubber sealing ring, comprising:

[0055]Step 1, weighing of raw materials: weighing of each raw material component according to the following parts by mass: 60 parts of liquid polysulfide rubber; 4 parts of propionate; 6 parts of epoxy group; 10 parts of bisphenol A epoxy resin; 5-15 parts of plasticizer; 7 parts of mixture of rosin resin and terpene resin; 8 parts of softener; 6 parts of carbon black; 8 parts of mixture of antimony trioxide and flame-retardant graphite; 8 parts of zinc peroxide; 17 parts of filler parts; the average particle size of flame-retardant graphite is 3000 mesh, and the average particle size of antimony trioxide is 0.7 microns.

[0056] Step 2, modification of liquid polysulfide rubber: under inert gas (nitrogen) conditions, polysulfide rubber is capped and modified with propionate and epoxy groups, and then mixed with bisphenol A epoxy resin to obtain modified polysulfide rubber. sulfur rubber;

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com