A kind of edible flame-retardant polyester fiber and its preparation method

A technology of flame-retardant polyester and fiber, applied in the field of polyester fiber, to achieve the effect of increasing activation energy, increasing thermal degradation temperature, and reducing droplet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

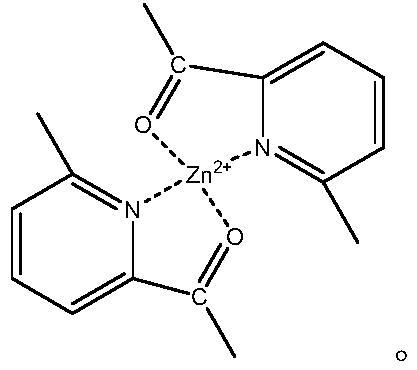

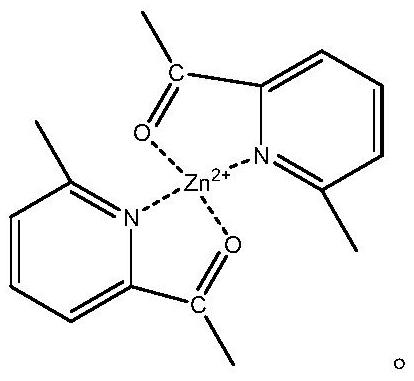

Image

Examples

Embodiment 1

[0053] A preparation method for taking flame-retardant polyester fiber, the specific steps are as follows:

[0054] (1) Preparation of modified polyester:

[0055] (1.1) Esterification reaction;

[0056] Terephthalic acid, ethylene glycol, 2,6-pyridinedicarboxylic acid and flame retardant 2-hydroxyethylphenylphosphorous acid with a molar ratio of 1:1.2:0.06:0.03 were made into a slurry, and the catalyst (three Antimony oxide), stabilizer (triphenyl phosphate) and zinc chloride are mixed evenly, the addition of catalyst and stabilizer is respectively 0.02wt% and 0.01wt% of terephthalic acid addition, the addition of zinc chloride It is 0.9mol% of the amount of terephthalic acid added; then pressurize in a nitrogen atmosphere to carry out the esterification reaction, the pressurized pressure is 0.2MPa, the temperature of the esterification reaction is 252 ° C, and the termination condition of the esterification reaction is: esterification The water distillation amount in the r...

Embodiment 2

[0072] A preparation method for taking flame-retardant polyester fiber, the specific steps are as follows:

[0073] (1) Preparation of modified polyester:

[0074] (1.1) Esterification reaction;

[0075] Terephthalic acid, ethylene glycol, 2,6-pyridinedicarboxylic acid and flame retardant 2-hydroxyethylphenylphosphorous acid with a molar ratio of 1:1.2:0.07:0.03 were made into slurry, and catalyst (three Antimony oxide), stabilizer (triphenyl phosphate) and zinc chloride are mixed uniformly, the addition of catalyst and stabilizer is respectively 0.01wt% and 0.02wt% of terephthalic acid addition, the addition of zinc chloride It is 1mol% of the amount of terephthalic acid added; then pressurize the esterification reaction in a nitrogen atmosphere, the pressurized pressure is 0.1MPa, the temperature of the esterification reaction is 250°C, and the termination condition of the esterification reaction is: esterification reaction The amount of water distilled in reaches 90% of t...

Embodiment 3

[0091] A preparation method for taking flame-retardant polyester fiber, the specific steps are as follows:

[0092] (1) Preparation of modified polyester:

[0093] (1.1) Esterification reaction;

[0094] Terephthalic acid, ethylene glycol, 2,6-pyridinedicarboxylic acid and flame retardant 2-hydroxyethylphenylphosphorous acid with a molar ratio of 1:1.2:0.08:0.03 were made into slurry, and catalyst (three Antimony oxide), stabilizer (trimethyl phosphate) and zinc chloride are mixed evenly, the addition of catalyst and stabilizer is respectively 0.03wt% and 0.02wt% of terephthalic acid addition, the addition of zinc chloride It is 1.1mol% of the amount of terephthalic acid added; then carry out the esterification reaction under pressure in a nitrogen atmosphere, the pressurized pressure is 0.2MPa, the temperature of the esterification reaction is 254°C, and the termination condition of the esterification reaction is: esterification The water distillation amount in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com