Self-healing ionic gel with high ionic conductivity and preparation and application thereof

An ion gel and ionic liquid technology, applied in the field of self-healing ion gel and its preparation, can solve the problems of environmental pollution, difficult degradation of fluorine-containing materials, poor mechanical properties and thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

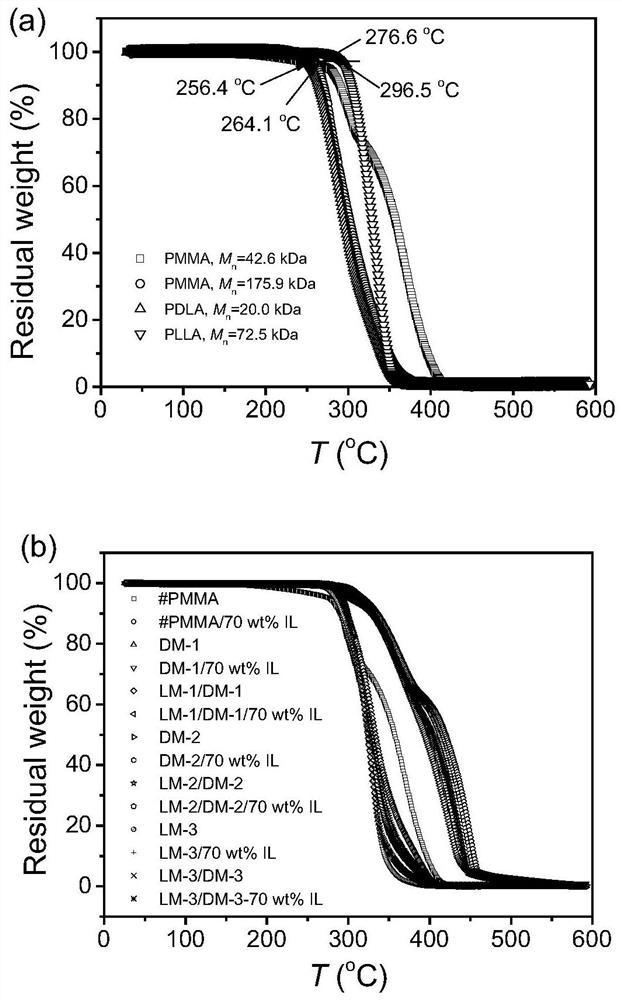

[0026] A method for preparing a self-healing ion gel with high ion conductivity, thermal stability and mechanical strength by blending PLA-b-PMMA diblock copolymers and ionic liquids, the specific steps are as follows:

[0027] 1. Synthesis of diblock copolymers PLLA-b-PMMA and PDLA-b-PMMA

[0028] 1) Add 0.149g of 2,2,2-trichloroethanol, 10g of L-lactide (D-lactide) and 8 μL of stannous isooctanoate into a self-made glass tube in an argon-protected glove box, vacuum After evacuating for 1 minute, seal the nozzle, polymerize at 130°C for 5 hours, then perform three cycles of chloroform dissolution-ethanol precipitation-suction filtration, and dry at 60°C for 3 days to obtain the prepolymer PLLA (PDLA). They are respectively recorded as PLLA-1 and PDLA-1, and the number 1 refers to the sample number;

[0029] 2) Take 2g of prepolymer PLA-1, 10g of methyl methacrylate, 5mg of cuprous chloride, 63μL of N,N,N',N",N"-pentamethyldiethylenetriamine and 10mL of Add dimethyl sulfoxid...

Embodiment 2

[0055] A kind of method utilizing PLA-b-PMMA diblock copolymer and ionic liquid blending to prepare high-performance ion gel, concrete steps are as follows:

[0056] 1. Synthesis of high molecular weight diblock copolymers PLLA-b-PMMA and PDLA-b-PMMA

[0057] 1) Add 0.025g of 2,2,2-trichloroethanol, 10g of L-lactide (D-lactide) and 8 μL of stannous isooctanoate into a self-made glass tube in an argon-protected glove box, vacuum After evacuating for 1 minute, seal the nozzle, polymerize at 130°C for 5 hours, then perform three cycles of chloroform dissolution-ethanol precipitation-suction filtration, and dry at 60°C for 3 days to obtain the prepolymer PLLA (PDLA). Denoted as PLLA-2 and PDLA-2, respectively;

[0058] 2) Take 1g of prepolymer PLA-2, 10g of methyl methacrylate, 1.7mg of cuprous chloride, 22μL of N,N,N',N",N"-pentamethyldiethylenetriamine and Add 10mL dimethyl sulfoxide into a 50mL Schlenk reaction flask, freeze-pump-thaw three times, react in a 90°C oil bath for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com