Patents

Literature

58results about How to "Increase mechanical tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

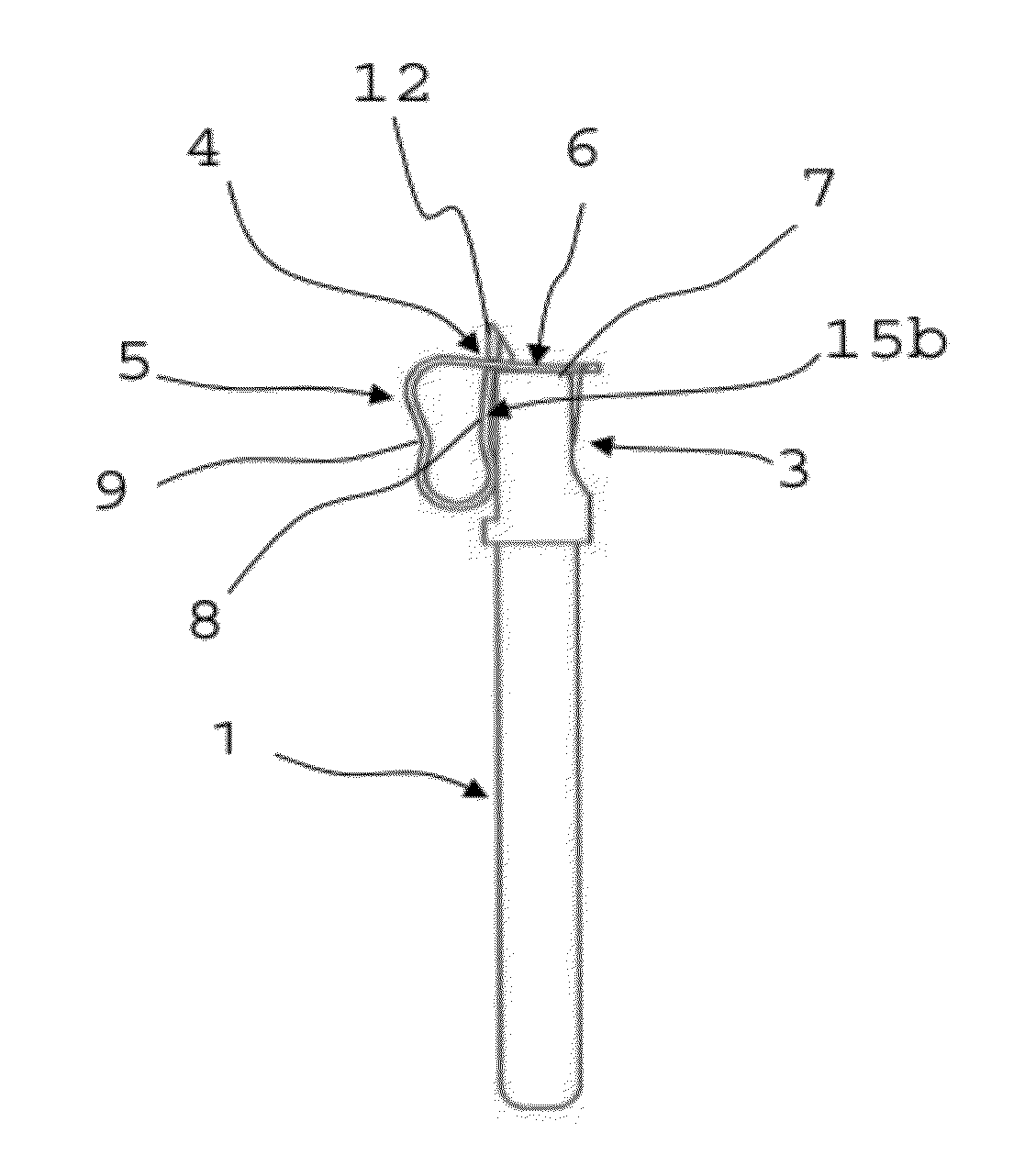

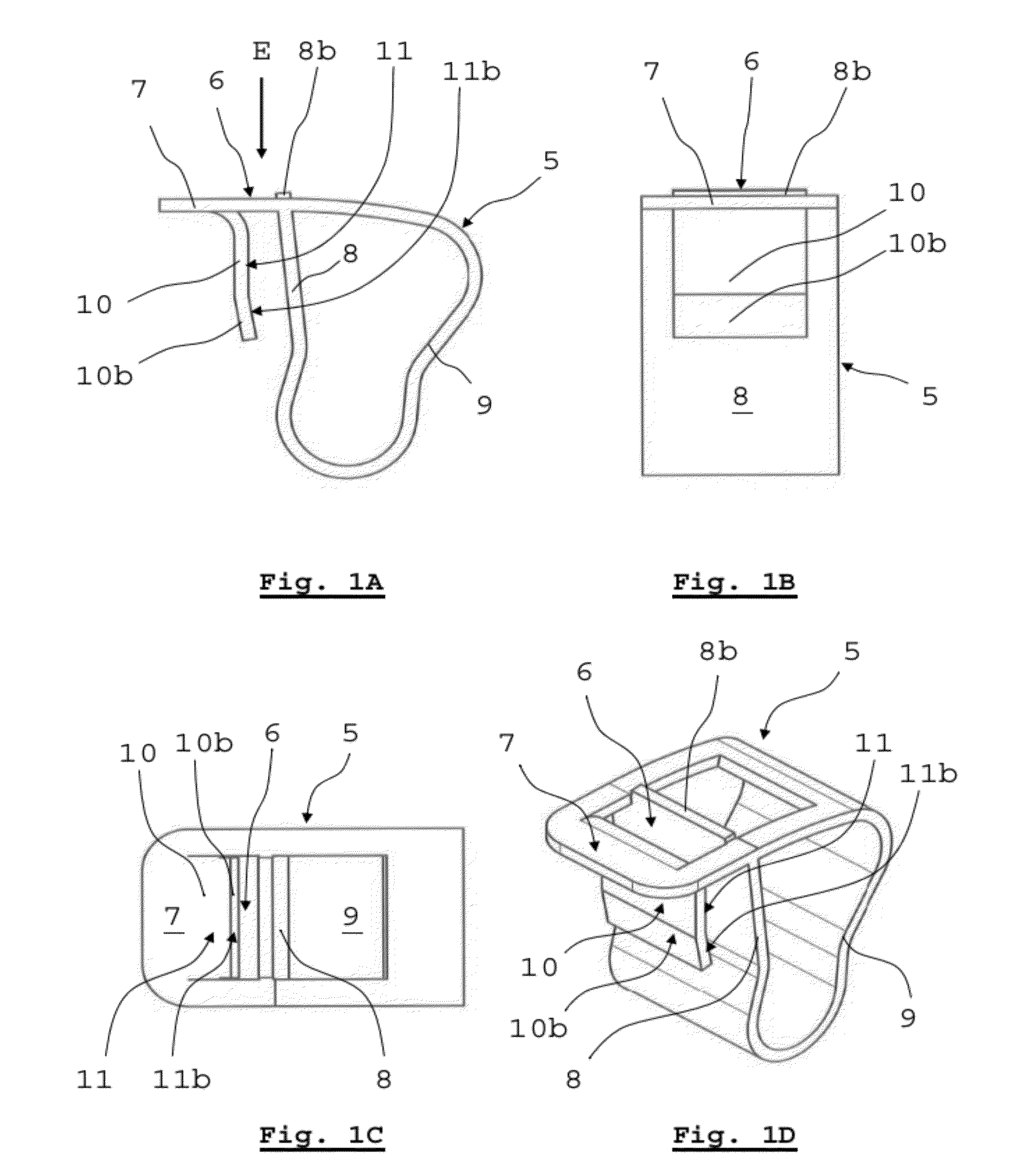

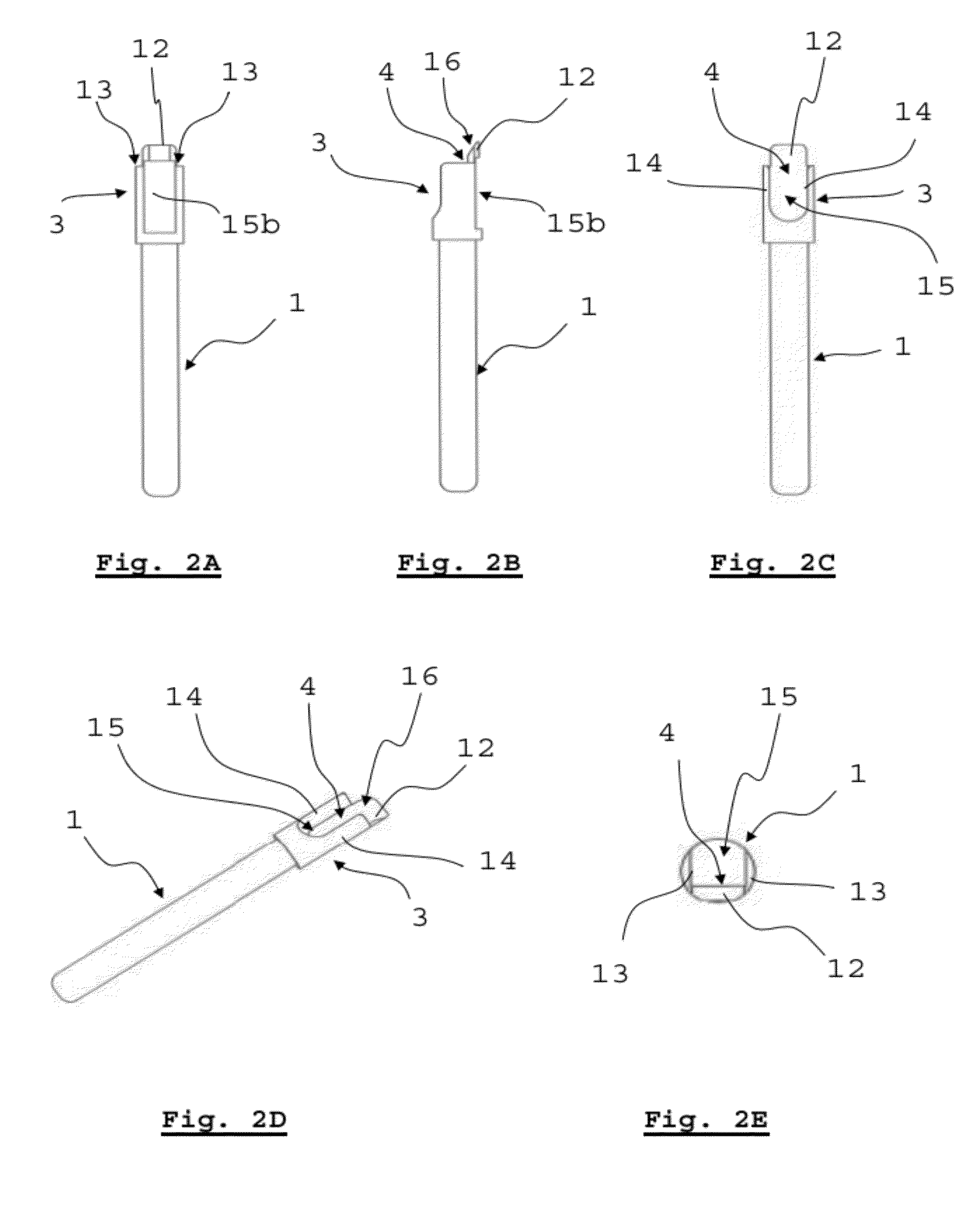

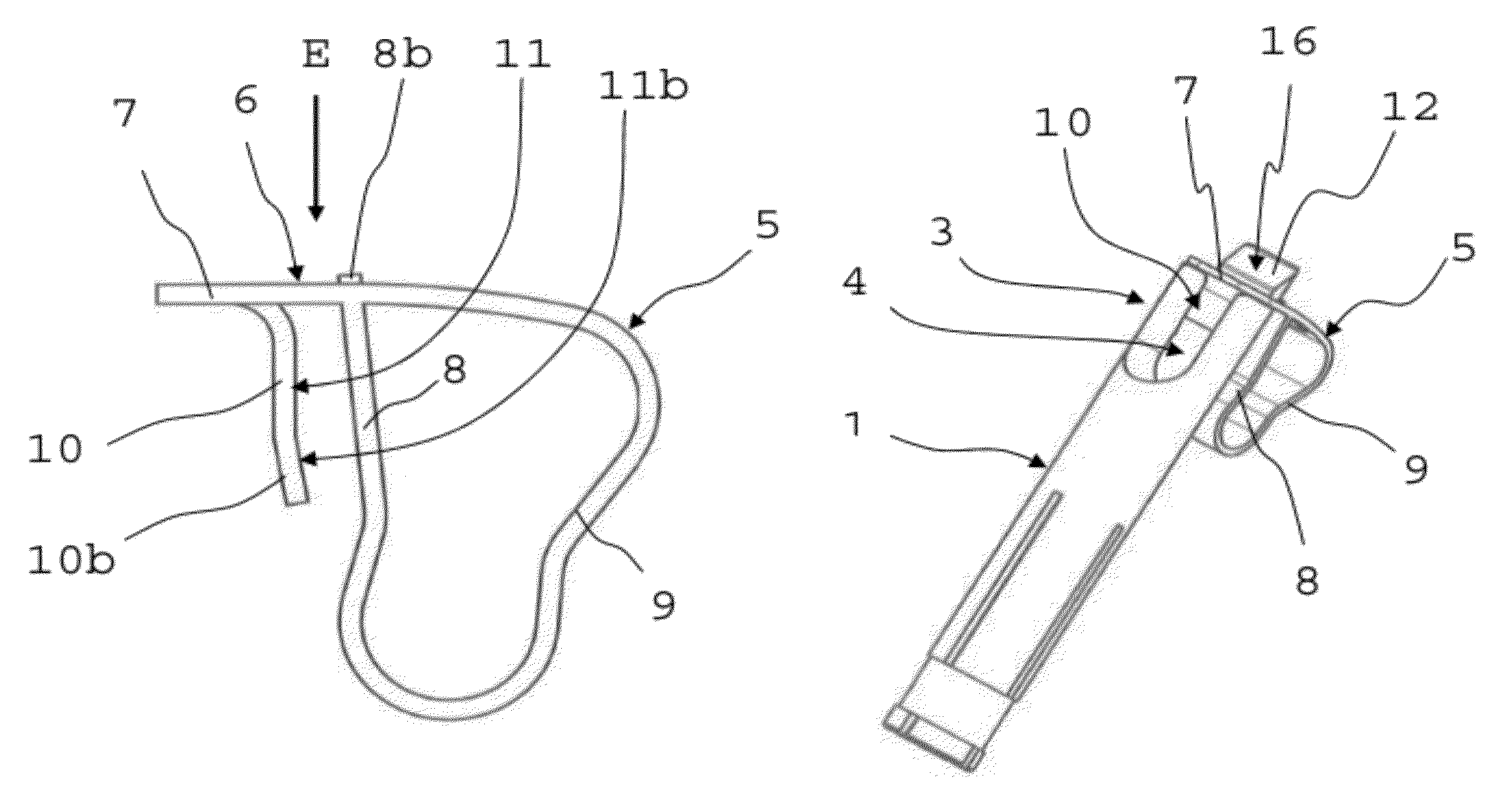

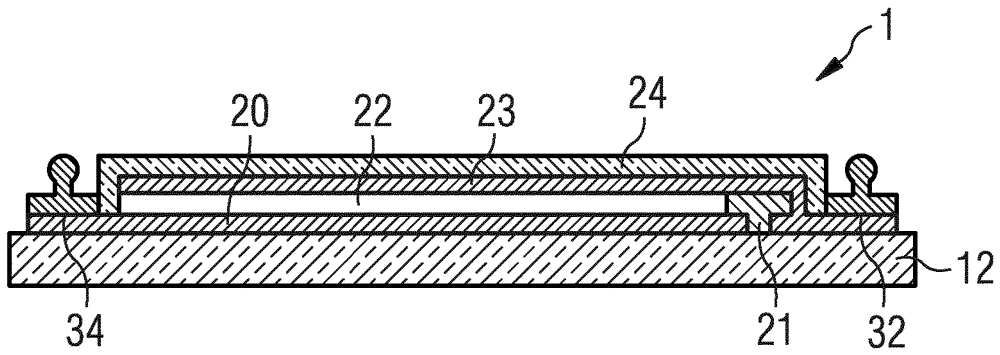

Screwless connection terminal

ActiveUS20120088415A1Low heat generationFirmly connectedLine/current collector detailsCoupling device detailsElectrical conductorElectrical connection

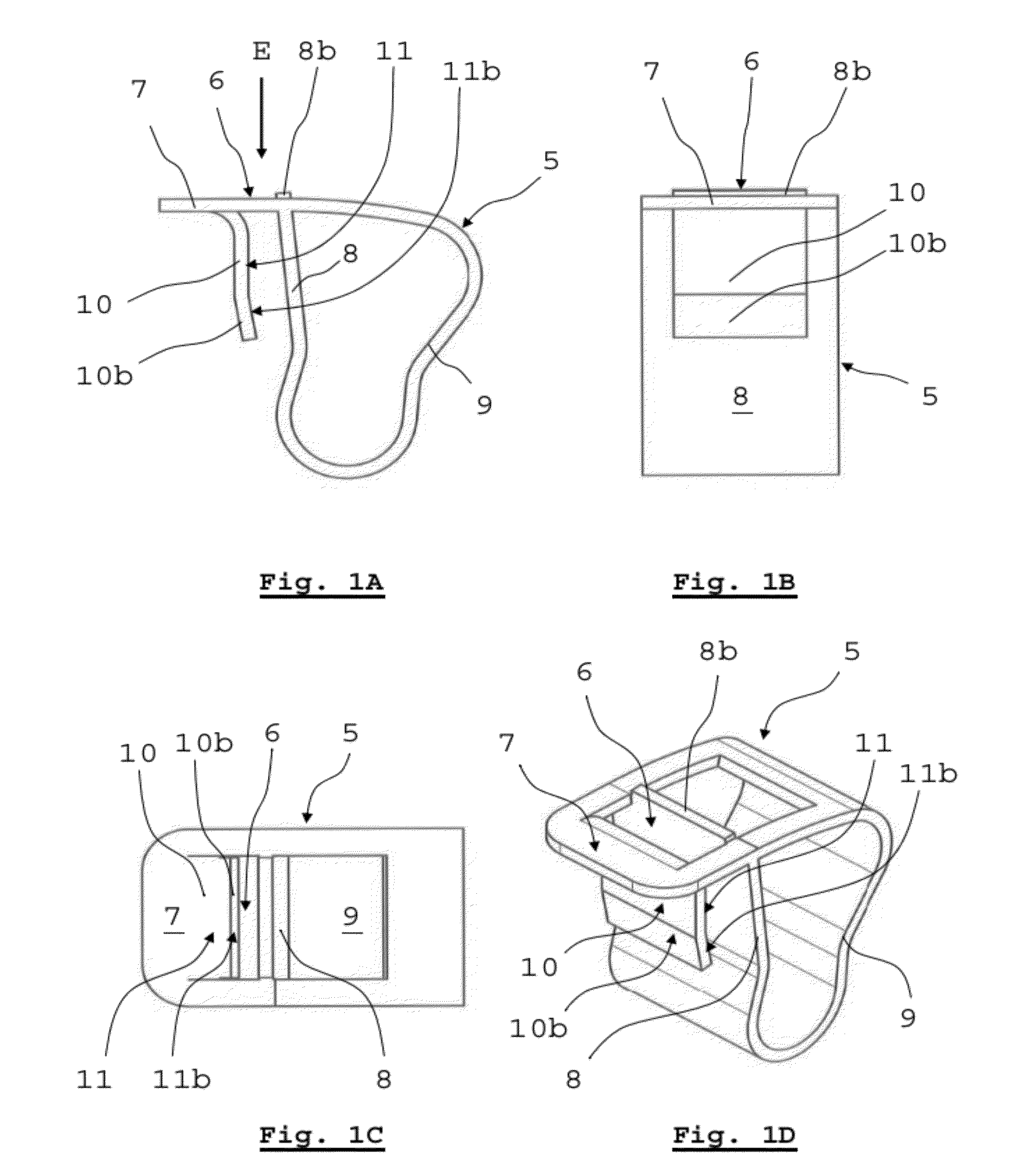

A screwless connection terminal with a contact element to which a conductor is to be electrically connected, the contact element comprising a connecting section and a contact surface, with a clamp spring by means of which the conductor is to be clamped to the contact surface of the contact element, wherein the clamp spring has a clamping leg, an abutting leg and a tensioning leg, wherein a clamp opening is formed in the clamping leg, through which clamp opening, the conductor is to be led, wherein the abutting leg of the clamp spring abuts on the contact element, and the tensioning leg of the clamp spring connects the abutting leg to the clamping leg, wherein the clamping leg further comprises a conductor clamp extension with a clamping face which is aligned substantially parallel to the contact surface of the contact element.

Owner:BALS ELEKTROTECHN

Preparation method of degradable polyglycolic acid

The present invention relates to a preparation method of degradable polyglycolic acid. The preparation method comprises the steps of 1) adopting glycolic acid as a raw material, subjecting glycolic acid to dehydrating and refining under the vacuum condition to obtain a glycolic acid oligomer; 2) mixing the obtained glycolic acid oligomer with a catalyst, adding mixed materials into a reaction vessel, and subjecting the materials to heating reaction under the vacuum condition to obtain a polyglycolic acid intermediate; 3) adding a chain extender MDI into the reaction vessel of the step 2), and subjecting materials in the reaction vessel to heating reaction under the vacuum condition to obtain the high-molecular weight polyglycolic acid.

Owner:桂林市福泰建材有限责任公司

Screwless connection terminal

ActiveUS8328588B2Low heat generationFirmly connectedCoupling device detailsClamped/spring connectionsElectrical conductorEngineering

A screwless connection terminal with a contact element to which a conductor is to be electrically connected, the contact element comprising a connecting section and a contact surface, with a clamp spring by means of which the conductor is to be clamped to the contact surface of the contact element, wherein the clamp spring has a clamping leg, an abutting leg and a tensioning leg, wherein a clamp opening is formed in the clamping leg, through which clamp opening, the conductor is to be led, wherein the abutting leg of the clamp spring abuts on the contact element, and the tensioning leg of the clamp spring connects the abutting leg to the clamping leg, wherein the clamping leg further comprises a conductor clamp extension with a clamping face which is aligned substantially parallel to the contact surface of the contact element.

Owner:BALS ELEKTROTECHN

Preparation method of polylactic acid with high molecular weight

The invention relates to a preparation method of polylactic acid with high molecular weight. The method comprises the preparation steps that 1, lactic acid is used as a raw material and dewatered and refined under a vacuum condition, and a lactic acid oligomer is obtained; 2, the lactic acid oligomer obtained in step 1 is mixed with a catalyst, the mixture is added into a reaction vessel, heating is carried out for a reaction under the vacuum condition, and a polylactic acid intermediate product is obtained; 3, a chain extender HDI is added into the reaction vessel in step 2, heating is carried out for a reaction under the vacuum condition, and the polylactic acid with high molecular weight is obtained.

Owner:桂林市福泰建材有限责任公司

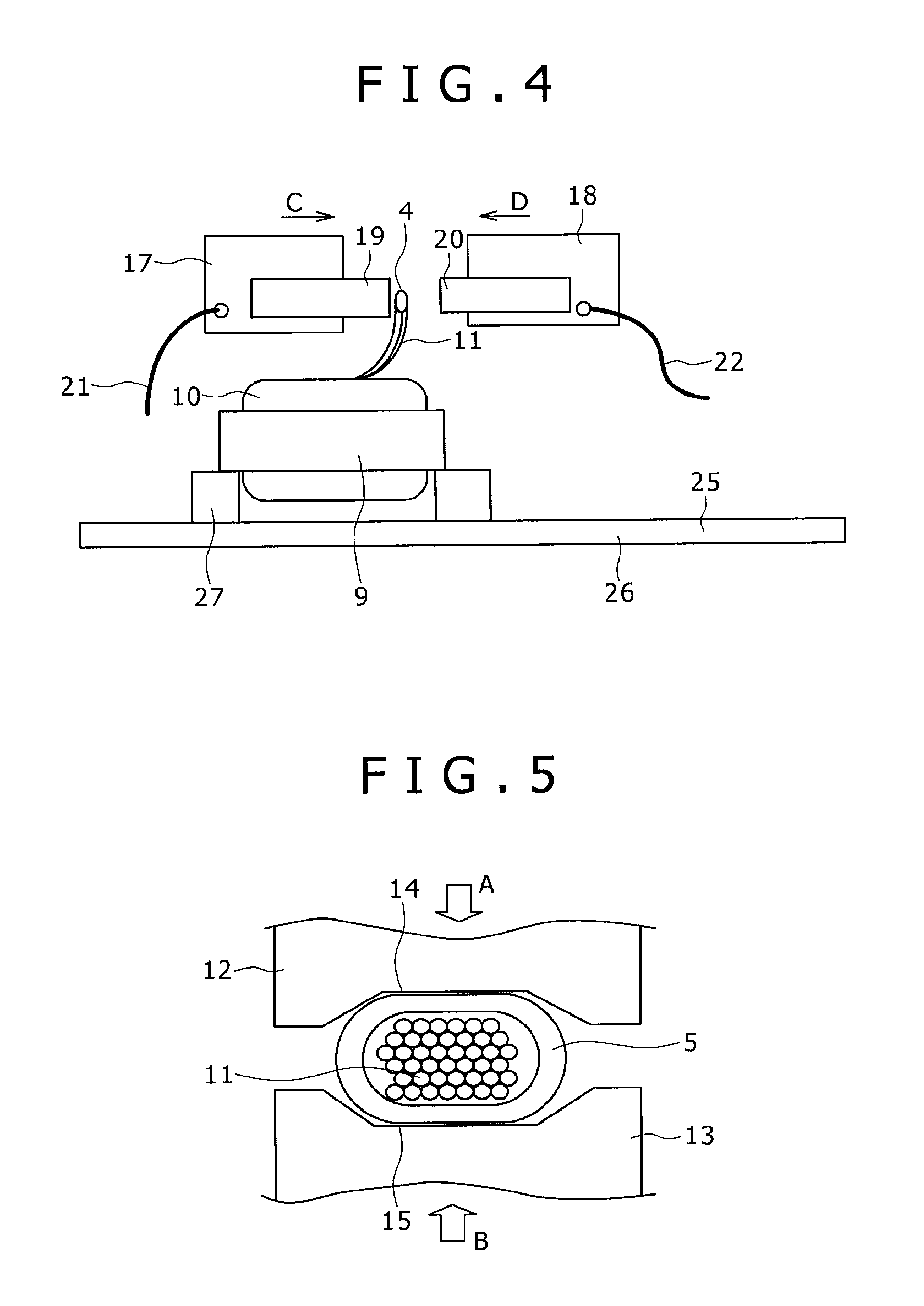

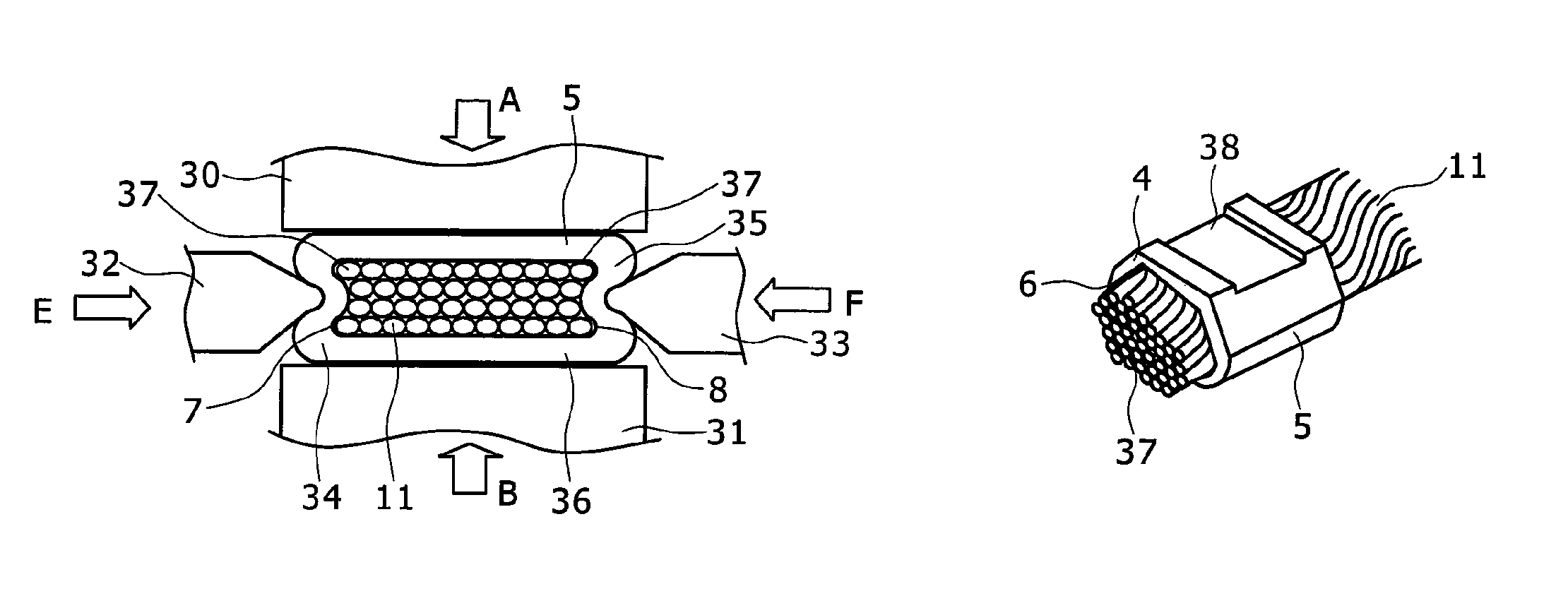

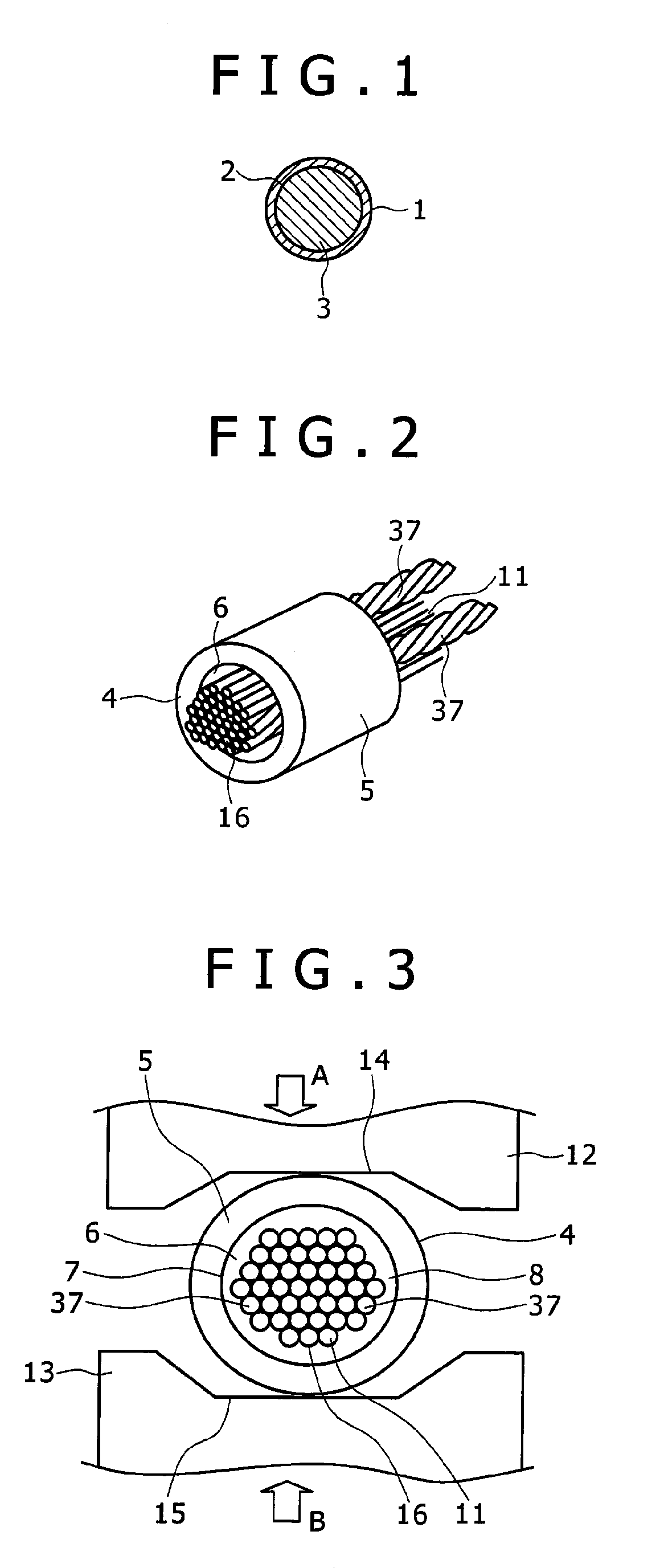

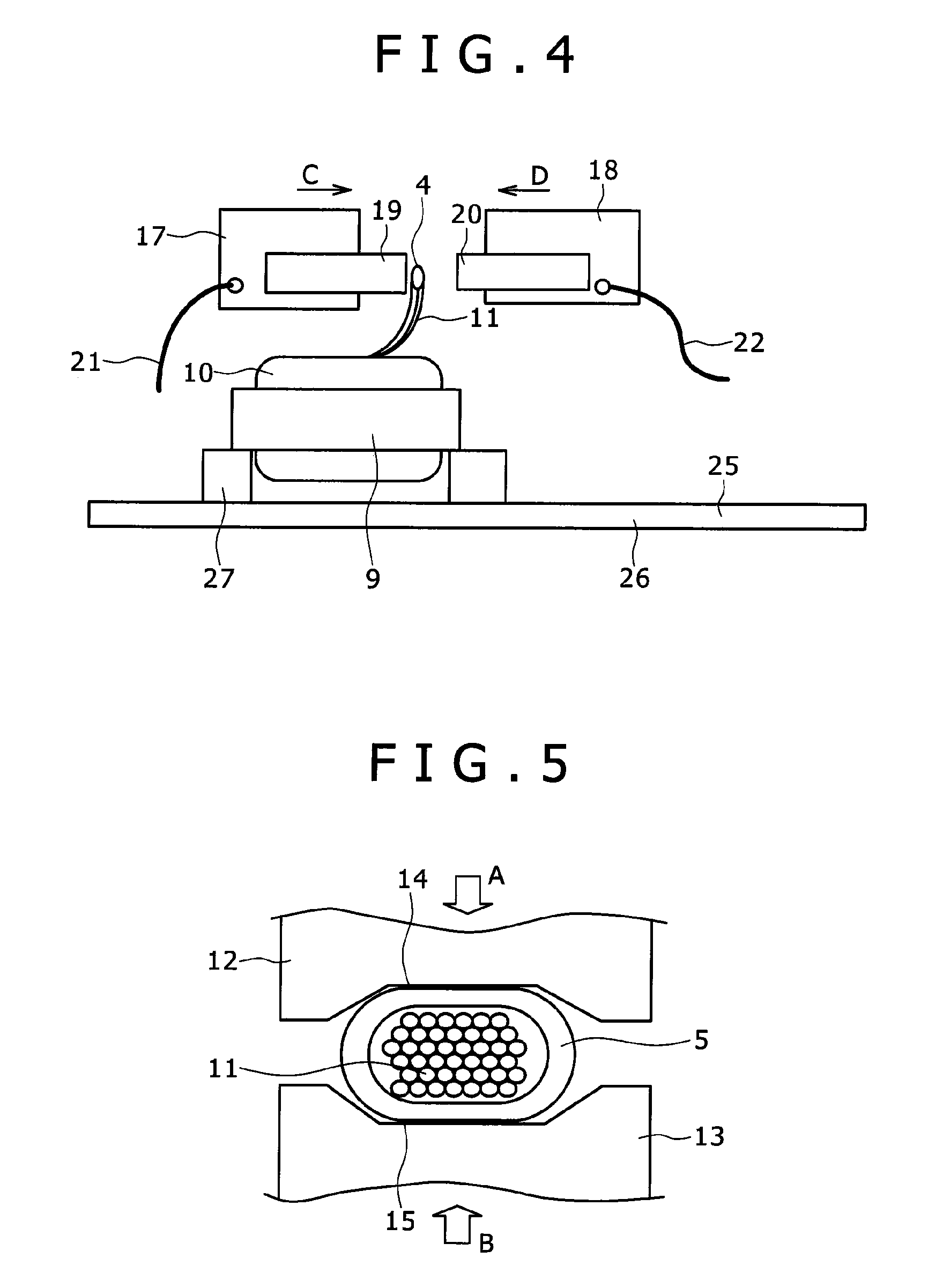

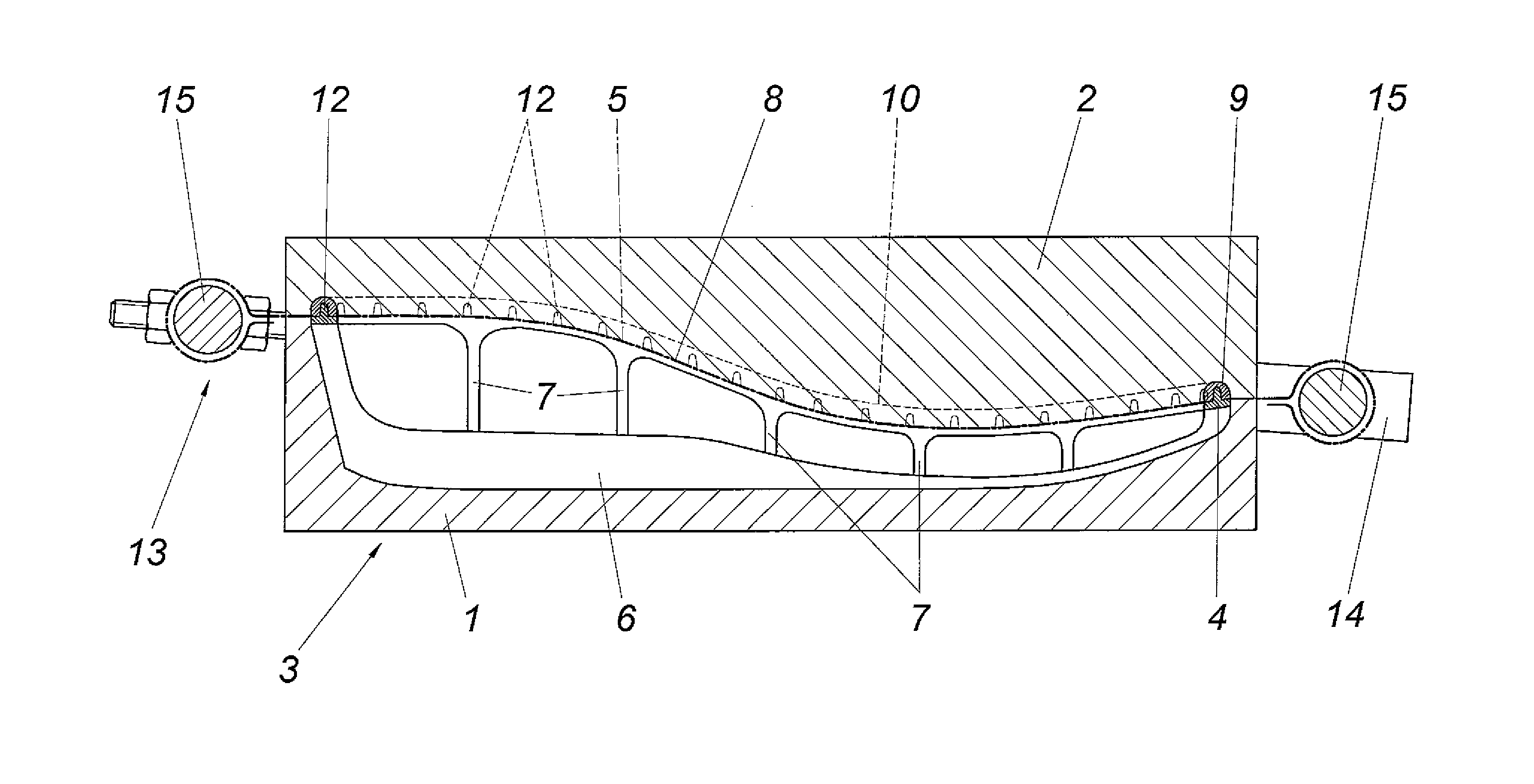

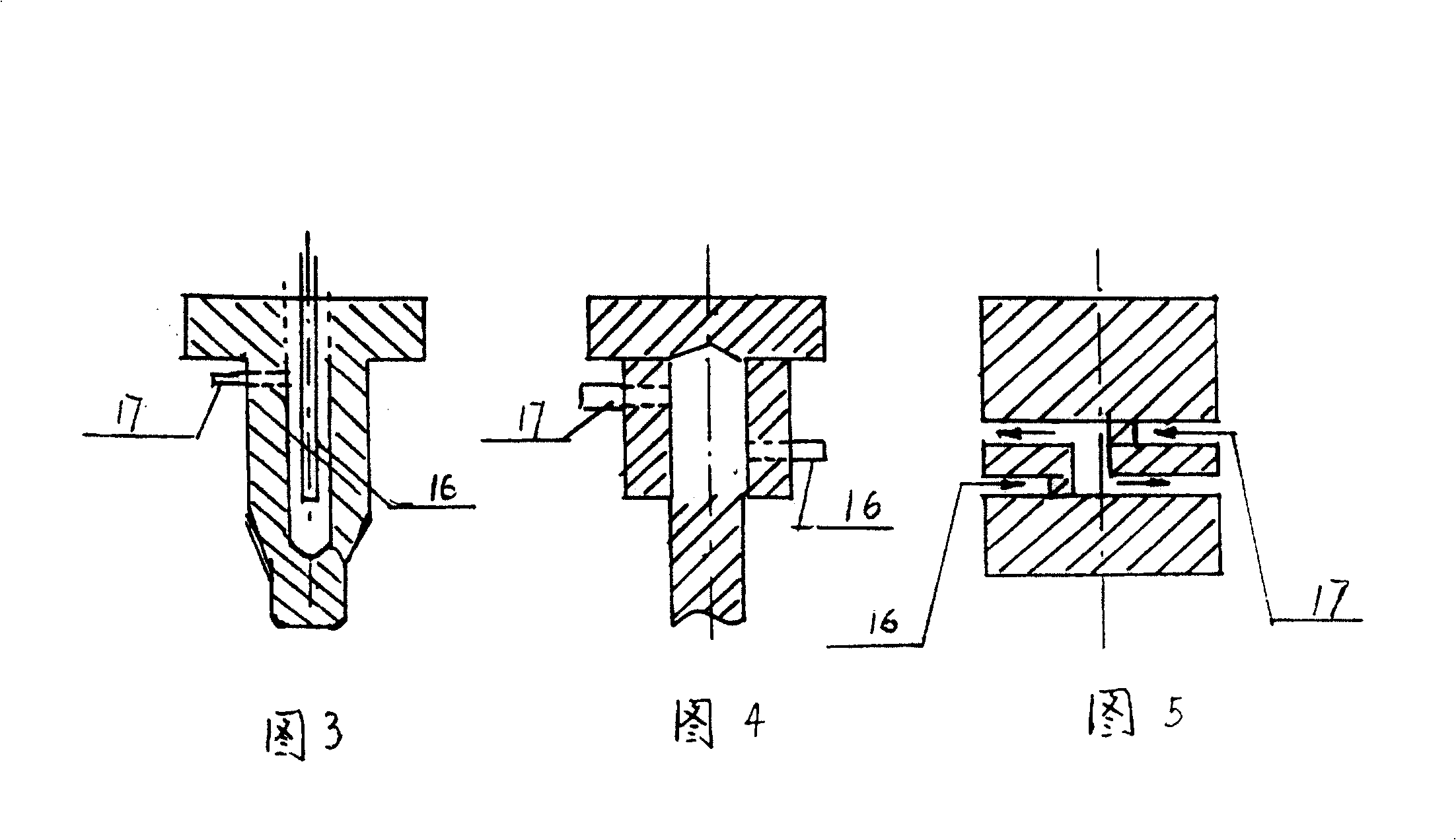

Conductor Wire Connecting Method, and Connecting Terminal, Stator, and Rotary Electric Machine

ActiveUS20120159783A1Increase mechanical tensile strengthIncrease crimping degreeConnections effected by permanent deformationConnection formation by deformationElectrical conductorElectric machine

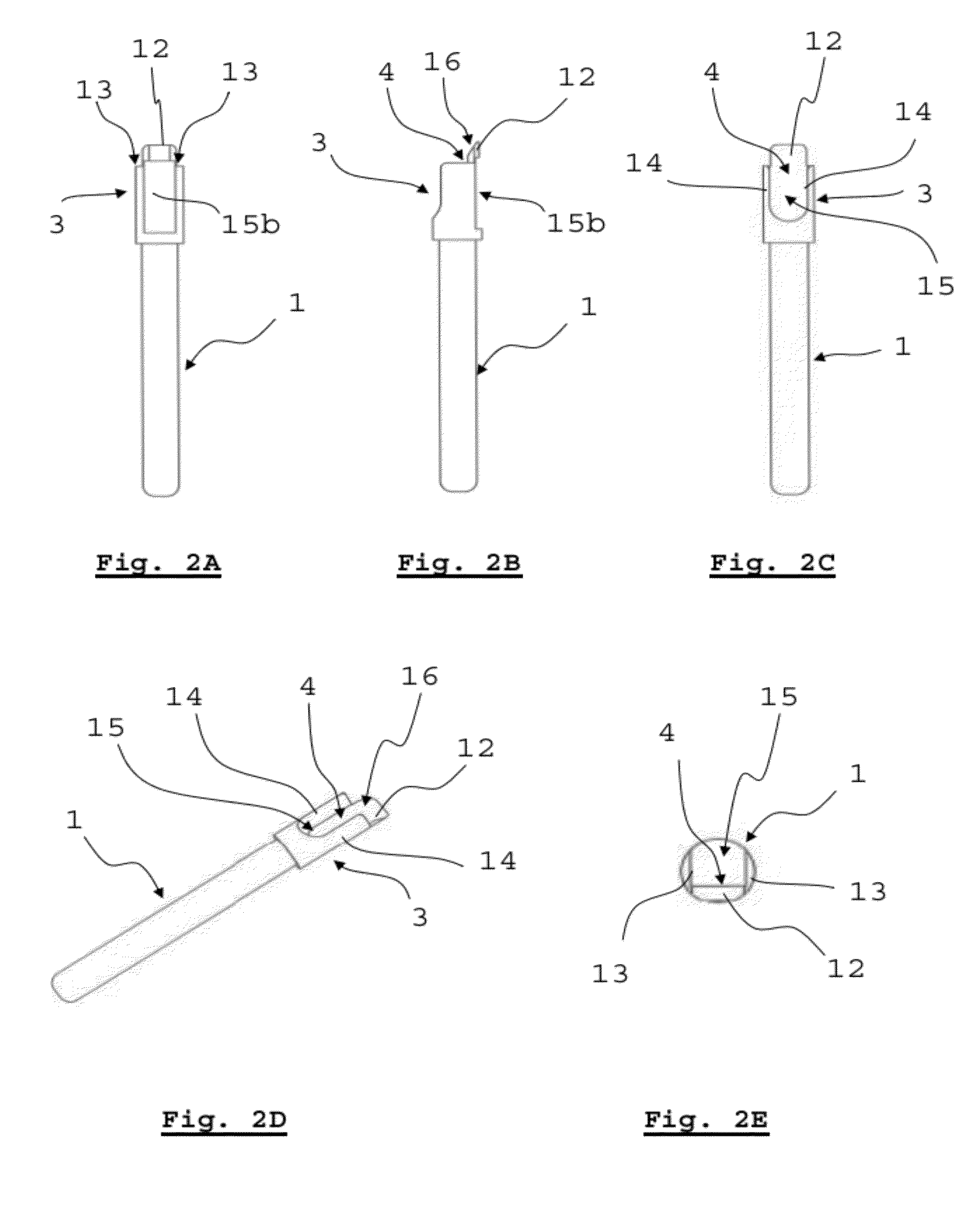

After melted enamel coating is discharged, a fusion process of electrical wire-to-wire connection is carried out inside a crimping connector. In the conductor connection method based on the fusion process, a plurality of enamel-coated conductor wires are inserted in the crimping connector prior to the start of the fusion process. Further, a temporary crimping process that provides the crimping connector a temporary crimping by mechanical pressurizing means is also performed. Addition of force at both end parts or either end part of the cross-section orthogonal to the axis of the above crimping connector may cause expansion, which needs to be suppressed with external force. At the same time, the cross-sectional areas corresponding to both end parts or either end part should preferably be as small as possible. The temporary crimping is applied to the crimping connector for this purpose.

Owner:HITACHI ASTEMO LTD

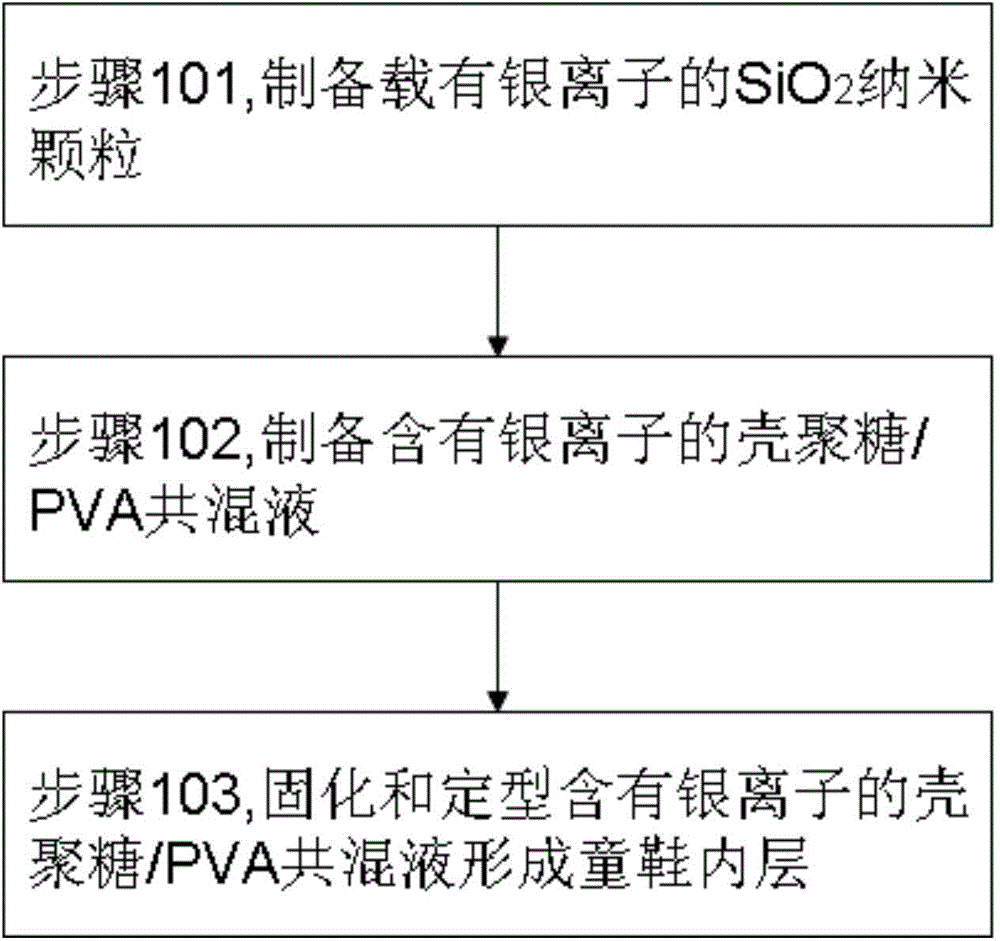

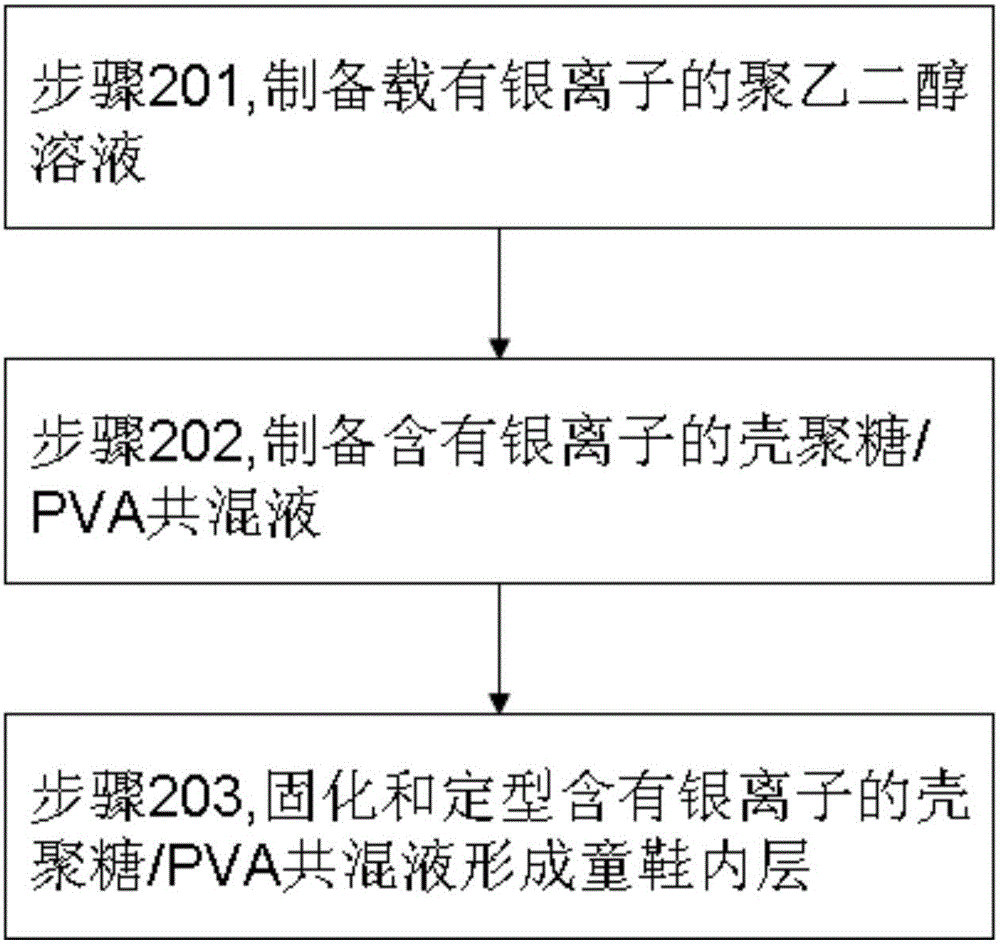

Antibacterial deodorizing children's shoe lining

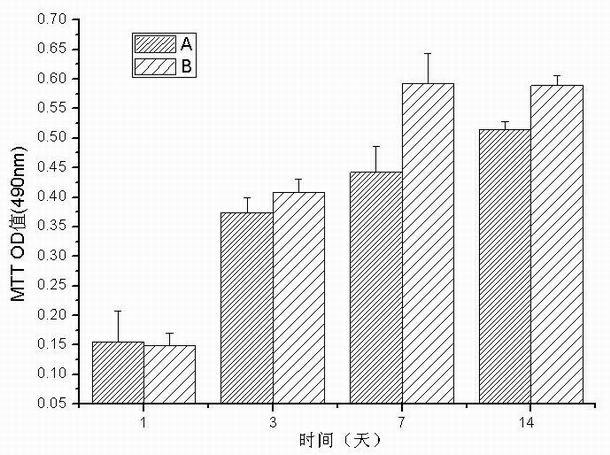

The invention provides an antibacterial deodorizing children's shoe lining made of nano composite material containing silver ions. The nano composite material is of matrix prepared through an acetalation PVA sponge, with high permeability and fine mechanical property, formed through chitosan composite. According to the children's shoe lining, the silver ions play bactericidal and antibacterial roles, the nano composite material has dense and uniform micro pores according to the micro structure, the water absorption performance is fine, the air permeability is high, and the volatilization of sweat in a shoe can be promoted; since the children's shoe lining and human organization are compatible, the toxic and side effect and stimulation are eliminated during direct skin contact, and large mechanical tensile strength can be maintained for a long term.

Owner:QIBU CHINA

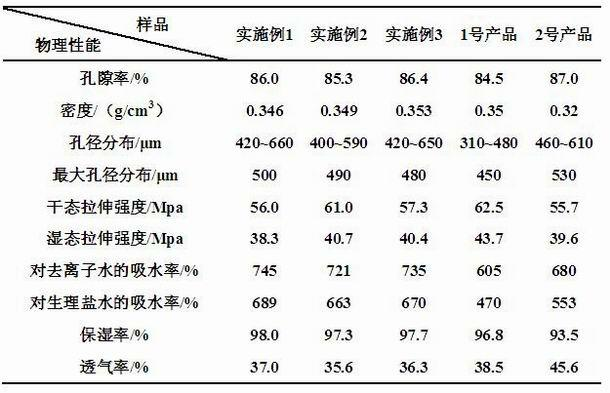

A kind of preparation method of chitosan composite acetalized polyvinyl alcohol medical dressing

ActiveCN102284080ABiocompatiblePromote wound healingAbsorbent padsBandagesSodium bicarbonatePolyvinyl alcohol

The invention discloses a method for preparing a chitosan compound acetalized polyvinyl alcohol medical dressing. The method comprises the following steps of: dissolving chitosan in an acetic acid aqueous solution to obtain a chitosan solution; mixing polyvinyl alcohol-AH26 and polyvinyl alcohol-1799, dissolving the mixture in boiled water, and uniformly mixing the mixture with the chitosan solution to obtain chitosan / polyvinyl alcohol blended solution; mixing the polyvinyl alcohol-AH26 and polyvinyl alcohol-1799, and dissolving the mixture in boiled water, adding sodium dodecyl sulfate, formaldehyde solution, sodium bicarbonate and hydrochloric acid, and stirring until foaming to obtain acetalized polyvinyl alcohol; and adding the polyvinyl alcohol / chitosan blended solution into the acetalized polyvinyl alcohol, injecting into a mold for solidifying to prepare the chitosan compound acetalized polyvinyl alcohol medical dressing. The medical dressing prepared by the method has biocompatibility, can promote wound healing, has high tensile strength, excellent air permeability, water absorption and foamability, does not have remarkable cytotoxicity, and can be used for treating wounds.

Owner:广州智焜生物科技有限公司

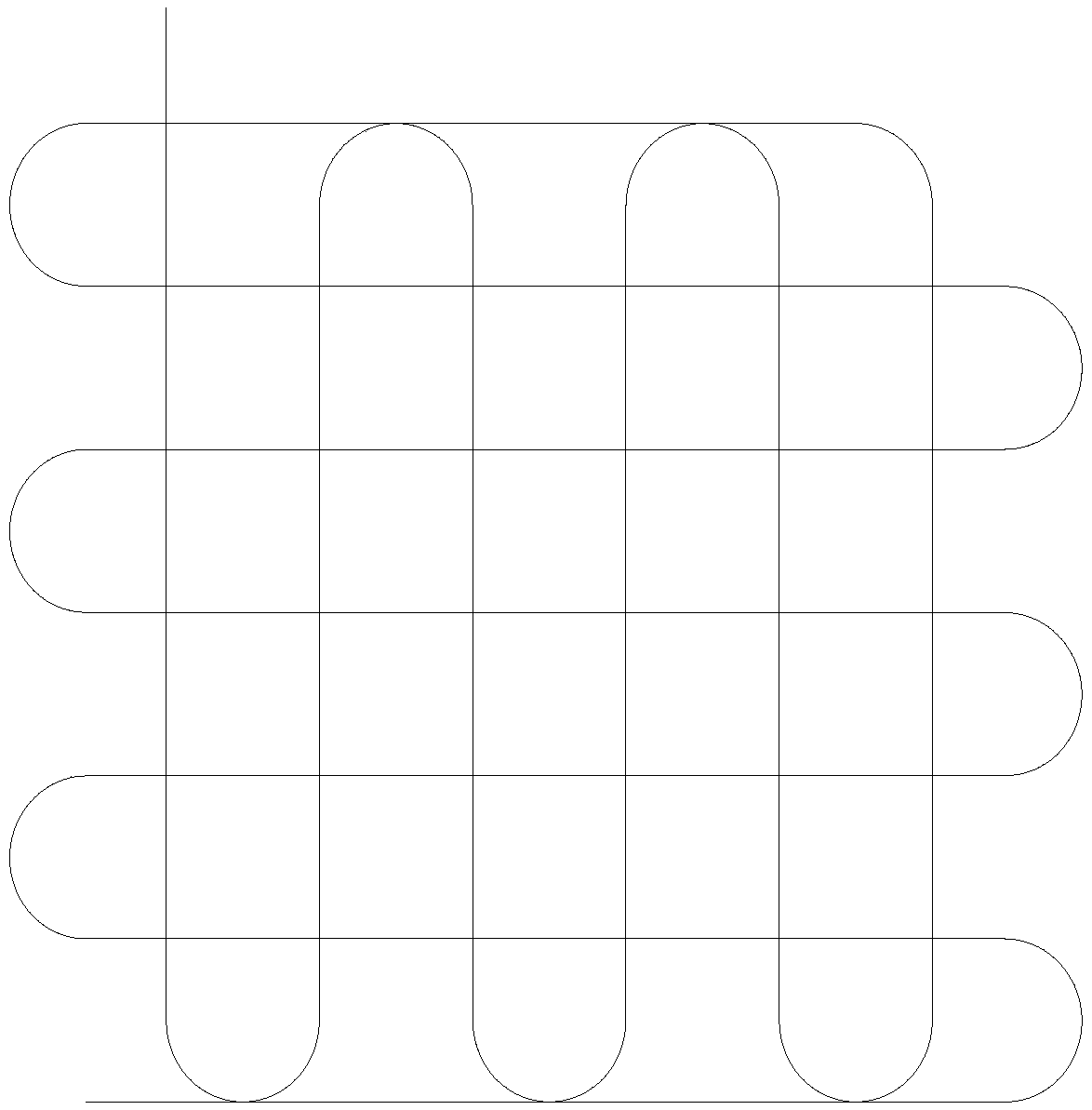

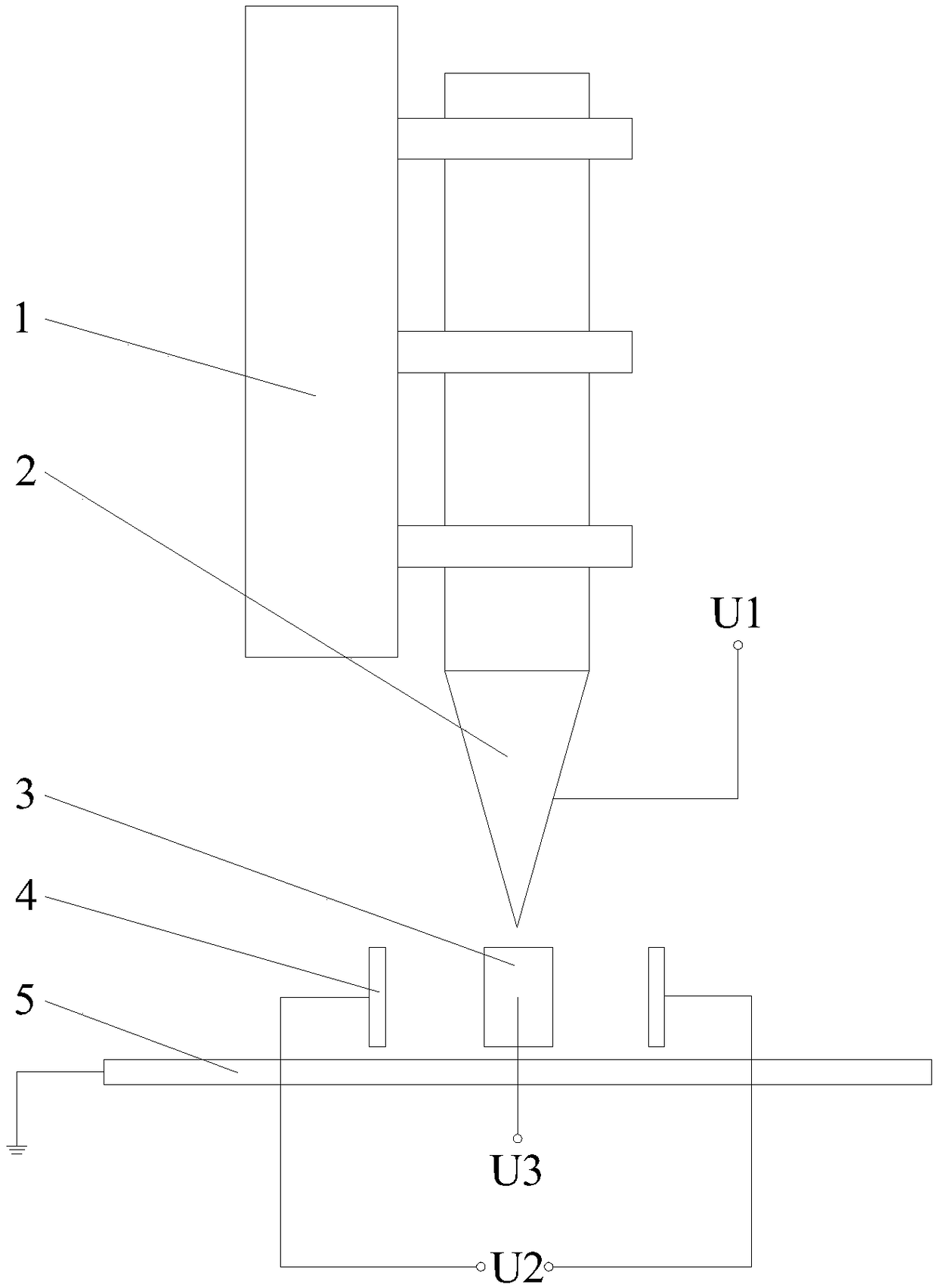

Lithium battery diaphragm, preparation method and electrostatic spinning device

InactiveCN109449357AExtended service lifeLower resistanceSecondary cellsCell component detailsElectrospinningVacuum drying

The invention discloses a lithium battery diaphragm. The lithium battery diaphragm comprises the following components in parts by weight: 93-96 parts of N,N-dimethylamide, 10-13 parts of polyacrylonitrile and 1-2 parts of lithium lanthanite oxide. A preparation method comprises the following steps of 1) mixing the N,N-dimethylamide and polyacrylonitrile powder to prepare a solution; 2) adding lithium lanthanite oxide powder into the mixed solution of the N,N-dimethylamide and the polyacrylonitrile, and carrying out uniform stirring by a stirrer; 3) putting a mixed solution into an electrostatic spinning device, carrying out sequential unidirectional spinning, namely, carrying out transverse reciprocating spinning first, and then carrying out longitudinal reciprocating spinning after the end is reached, until an initial point is reached; and continuing the next spinning to ensure that a fiber has three layers, wherein technological parameters of the electrostatic spinning device are asfollows: an electrostatic voltage is 15-20KV, a jet speed is 0.2-0.71ml / h, and a receiving distance is 16cm; and 4) carrying out vacuum drying on the fiber subjected to spinning forming at 45 DEG C for 5 hours so as to complete the preparation. The lithium battery diaphragm is high in structural strength, high in liquid absorption capacity, high in ionic conductivity, and convenient and fast to prepare.

Owner:苏州华骞时代新能源科技有限公司

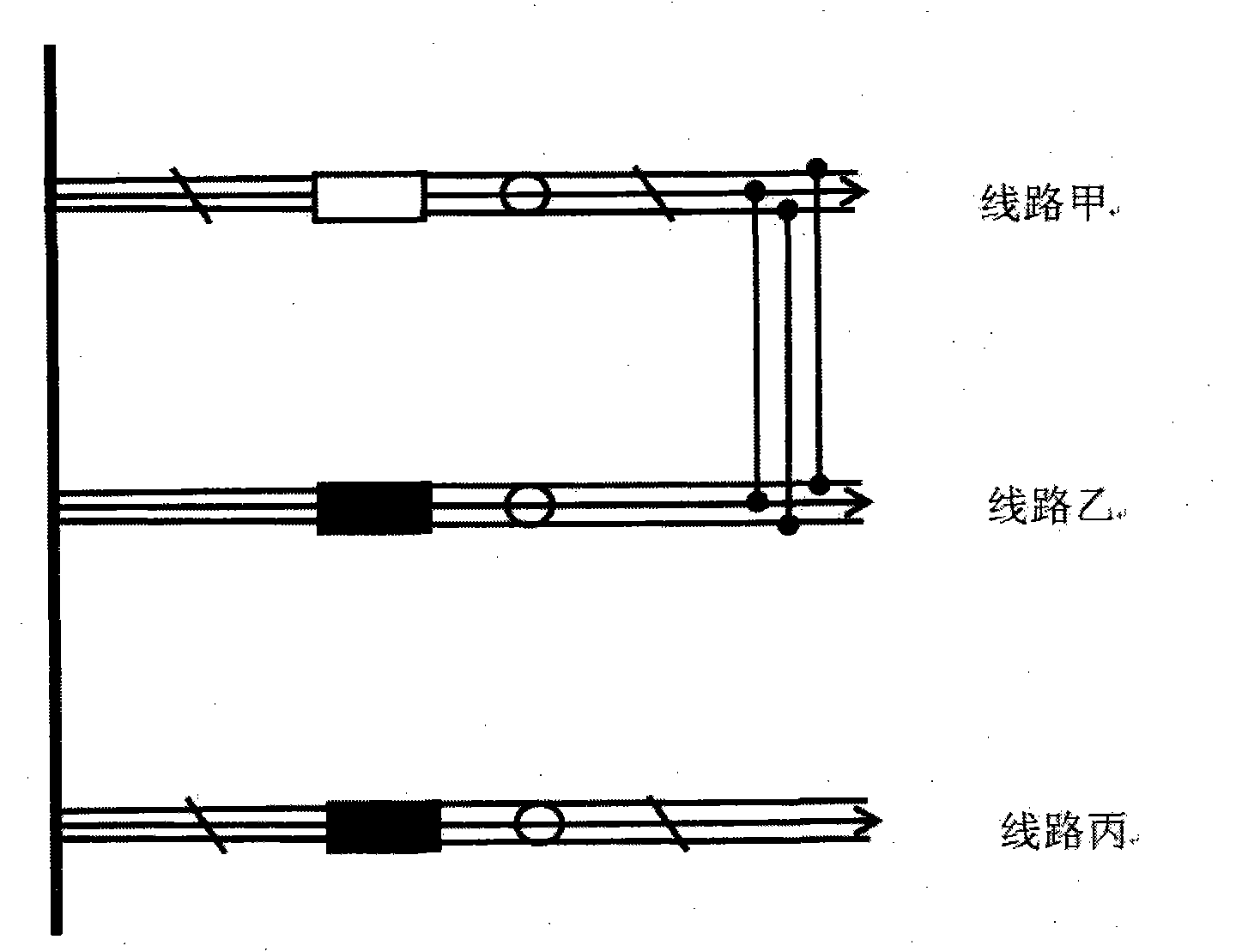

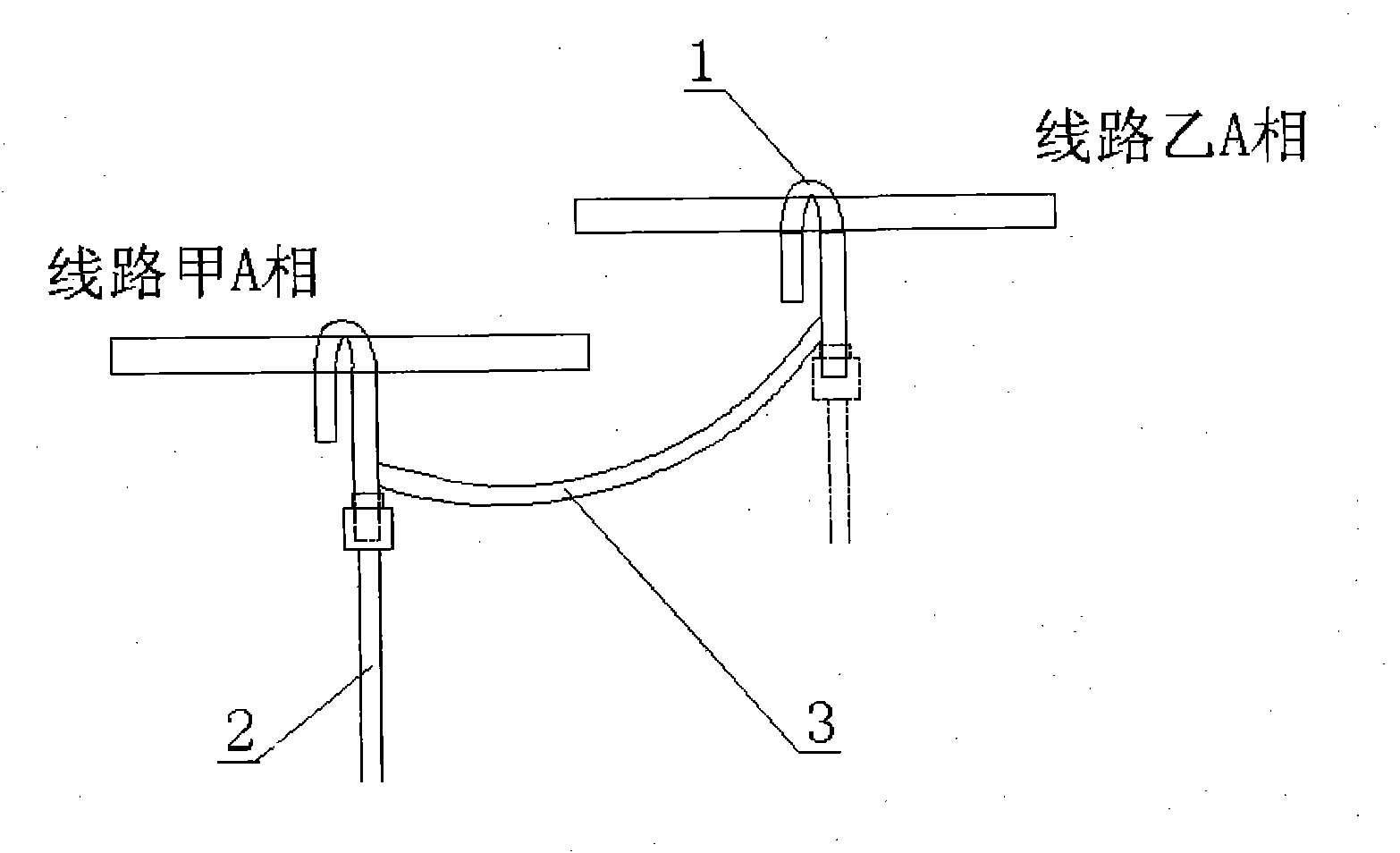

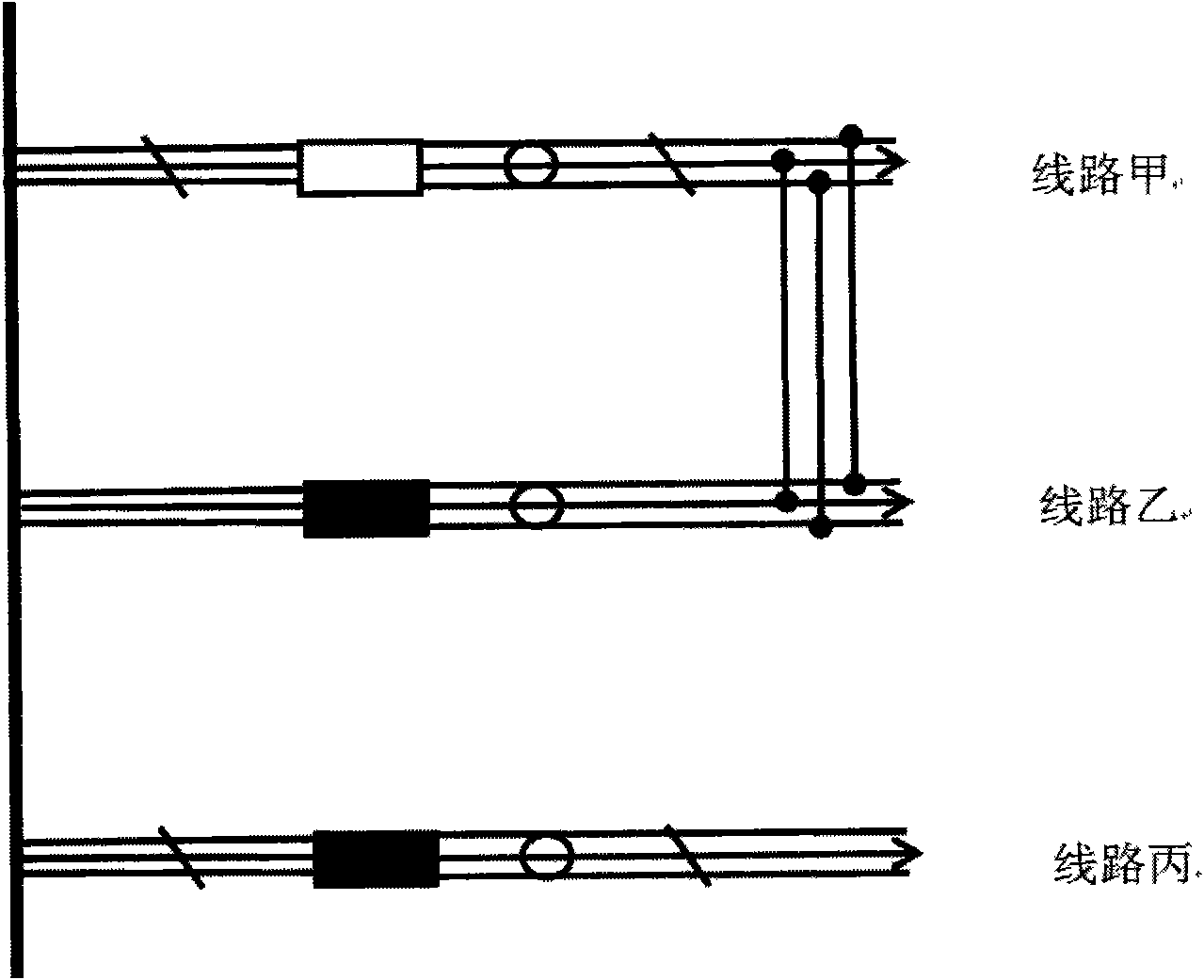

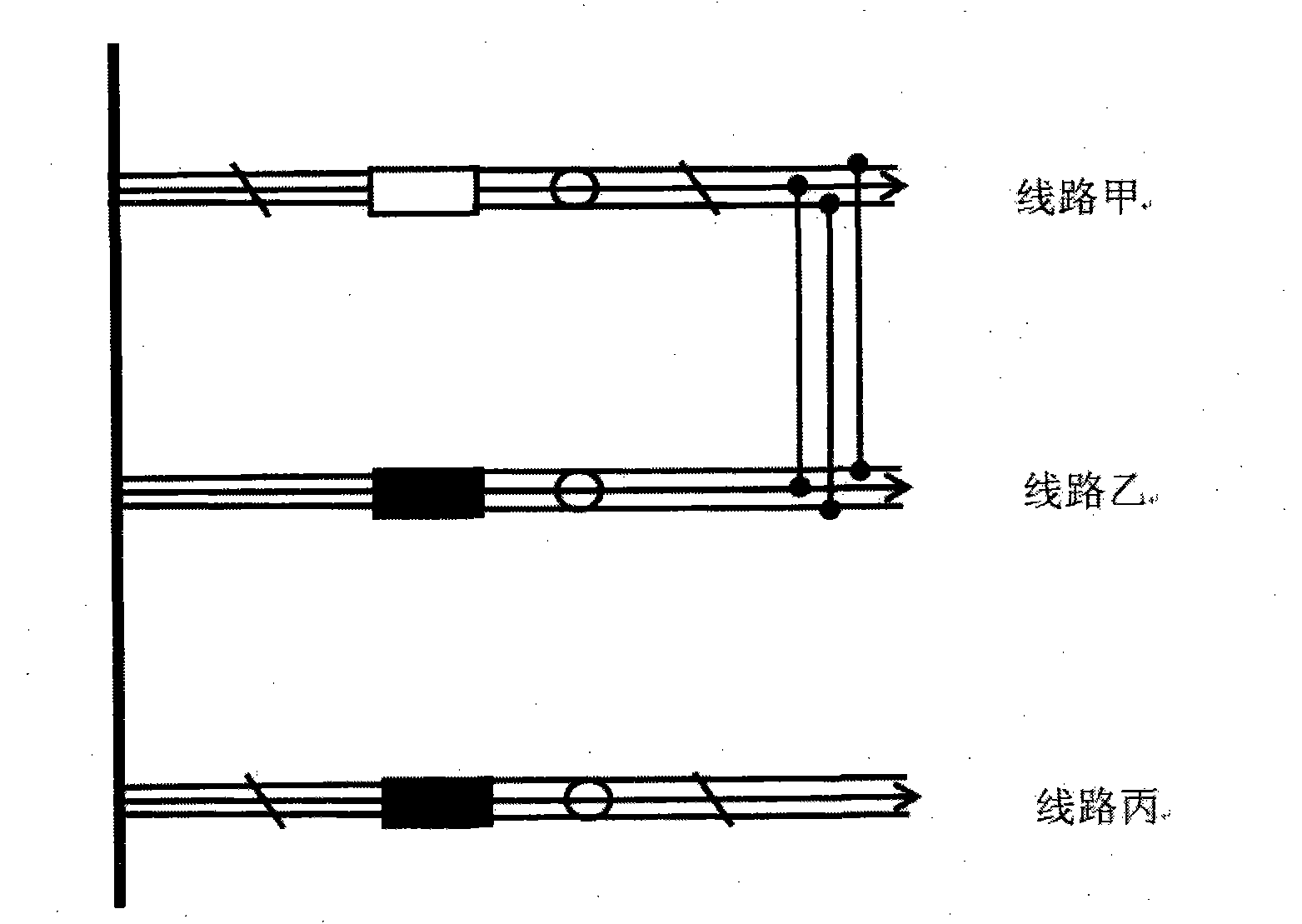

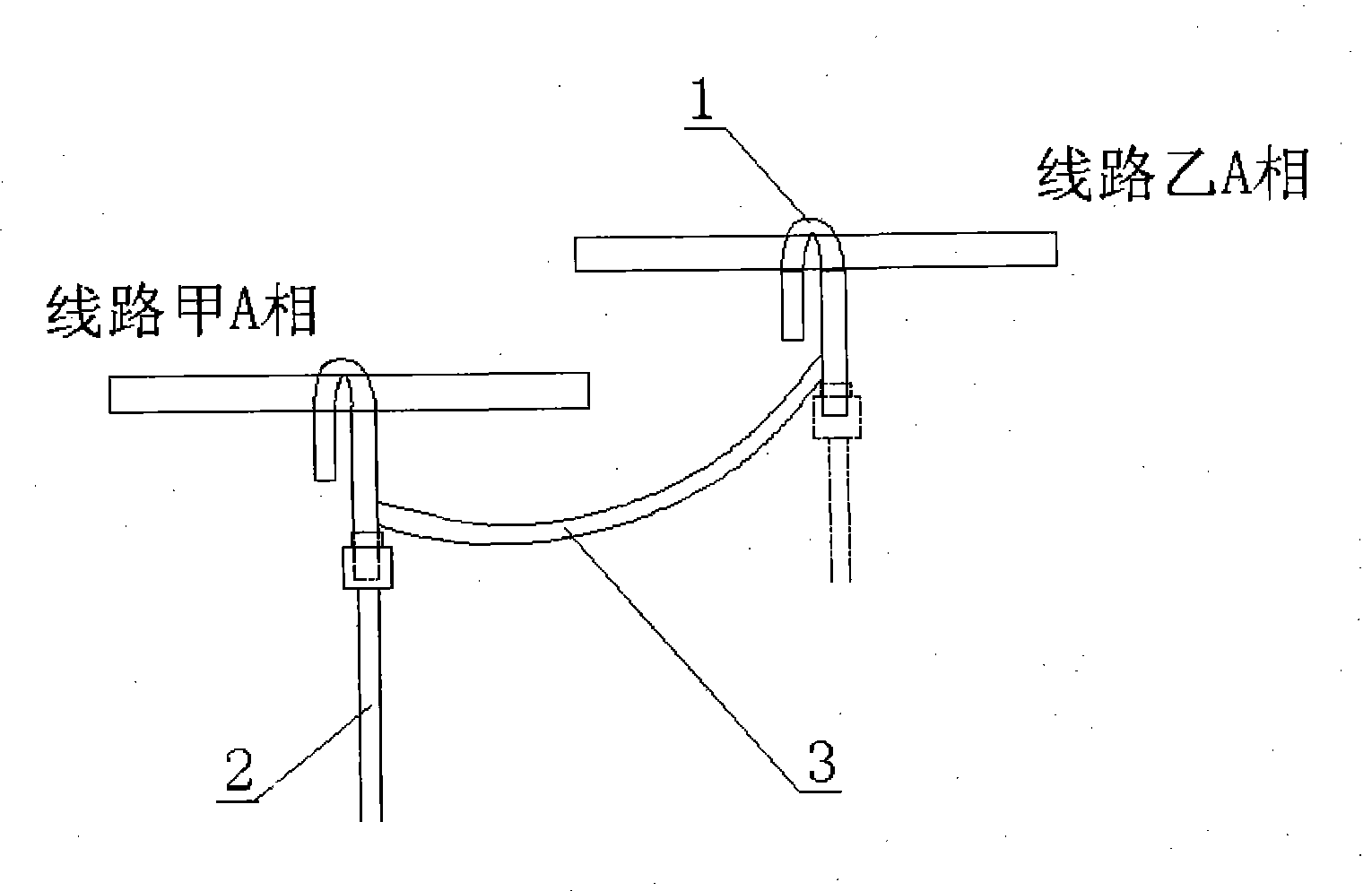

New line bridging method and special bridging line

InactiveCN102064498AReduce weightEasy to operateApparatus for overhead lines/cablesEngineeringElectrical and Electronics engineering

Owner:STATE GRID CORP OF CHINA +1

Manufacturing method of multi-wire combined welding cable

Owner:江苏霍斯特电气科技有限公司

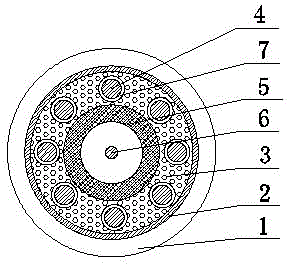

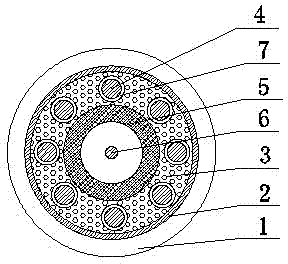

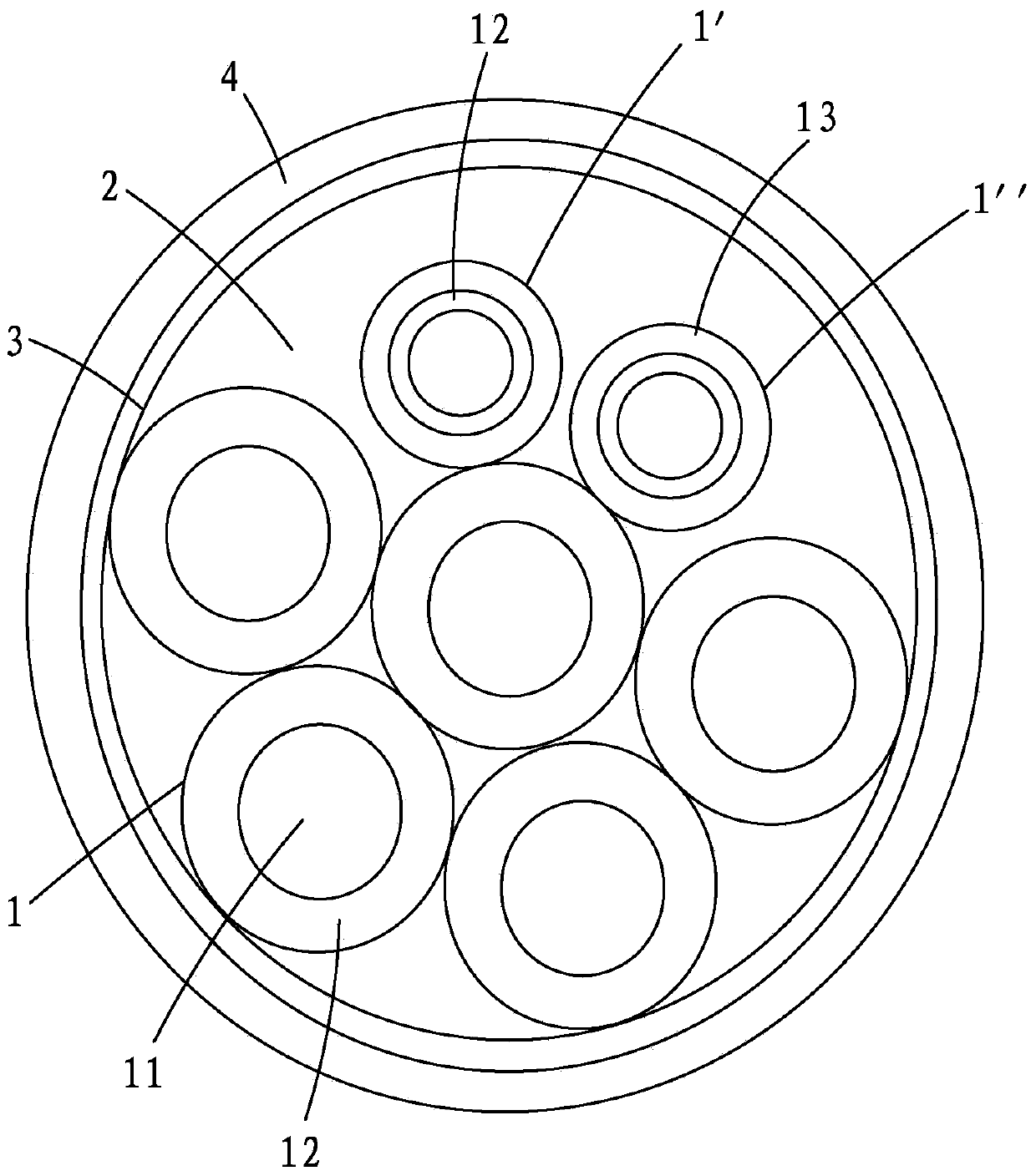

Multi-wire combined welding cable typed II and production method thereof

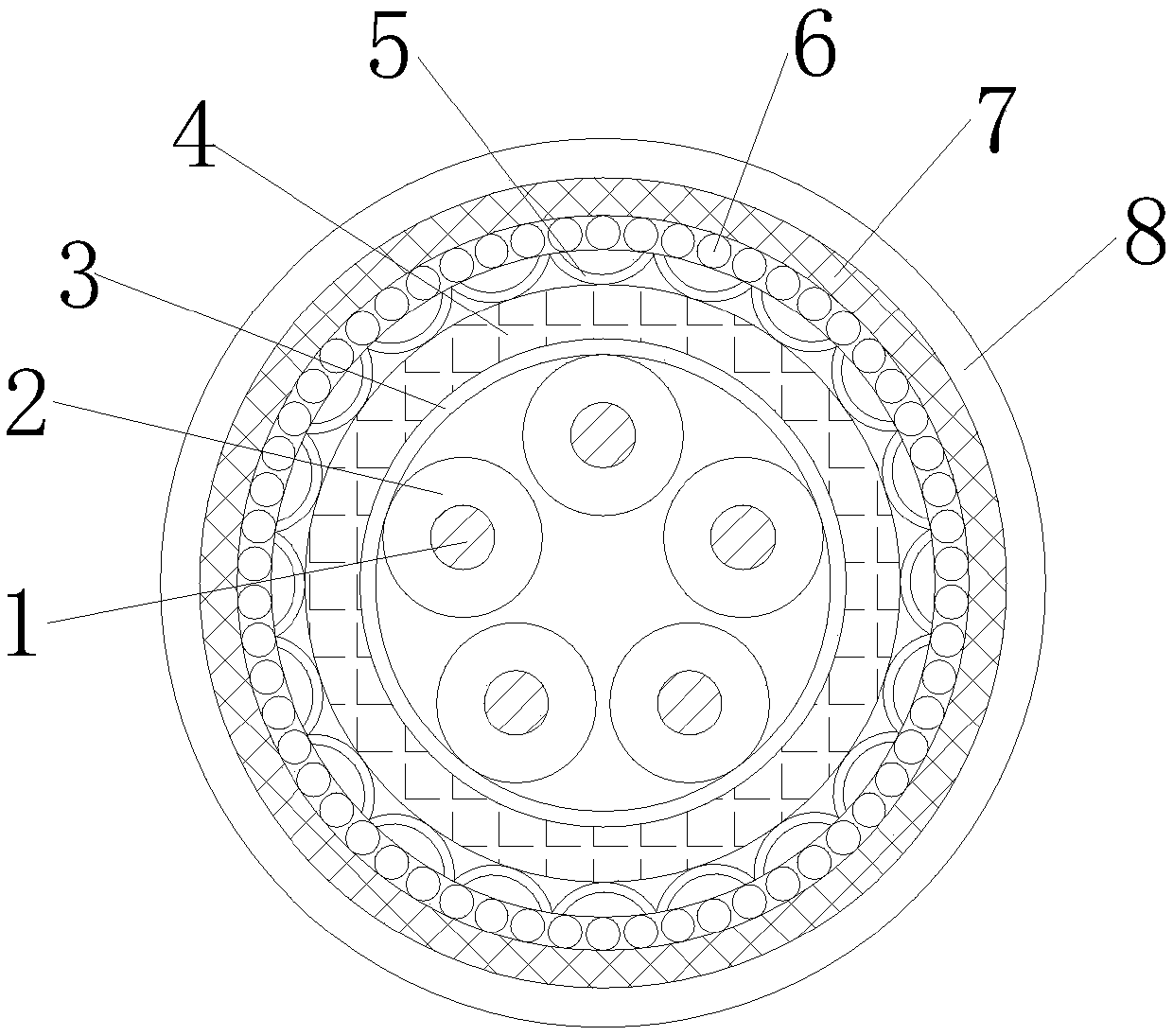

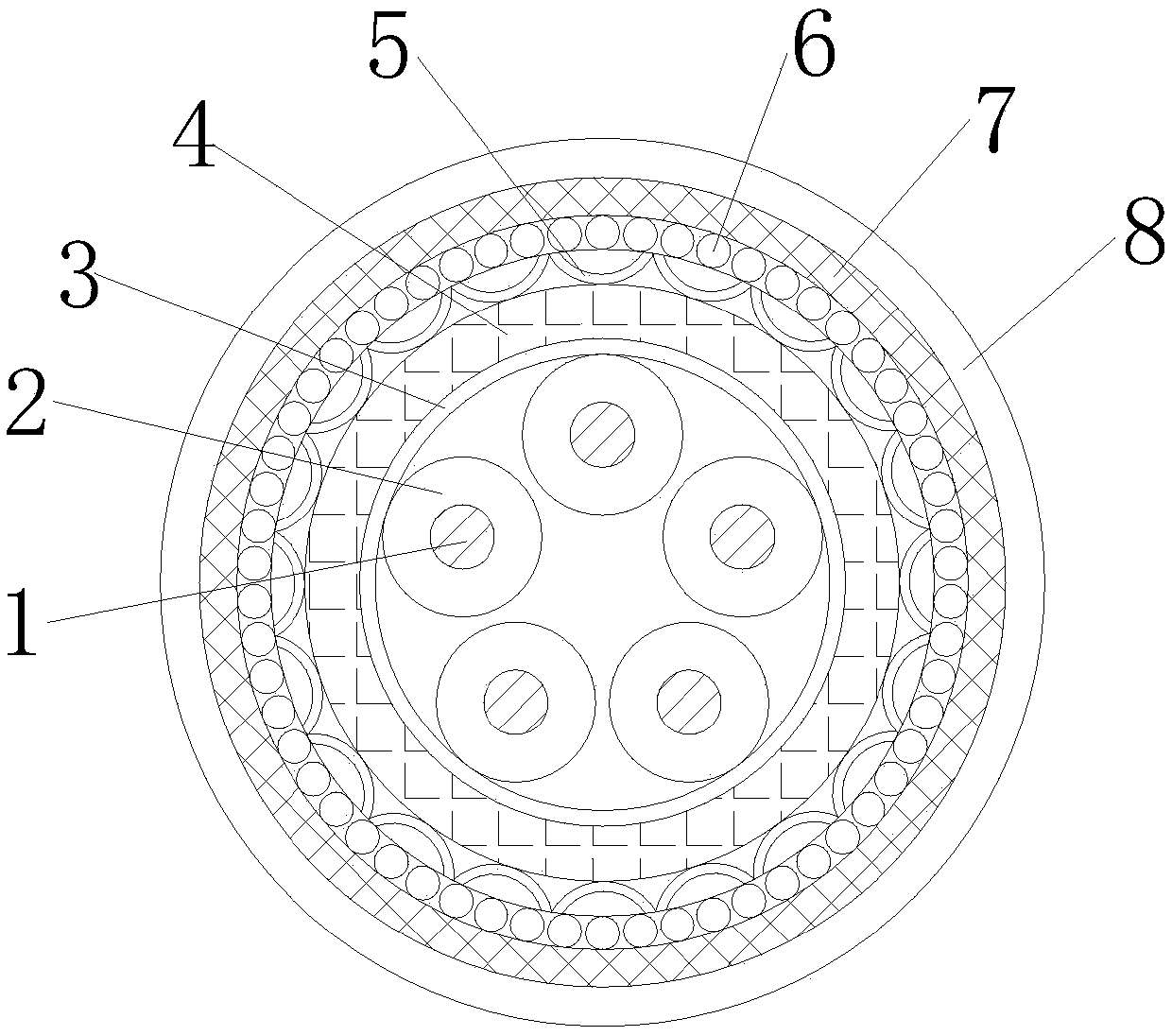

The invention relates to a multi-wire combined welding cable typed II and a production method thereof and belongs to the technical field of cables. The multi-wire combined welding cable typed II comprises current conductors, a plurality of signal control cables, an inert gas pipe, a signal control carrier line, an outer sheath and the like. The current conductors are made by twisting a plurality of flexible oxygen-free copper wires. The inert gas pipe is made of flexible elastomer combined polyvinyl chloride insulating material. The signal control carrier line is made by twisting a plurality of annealed thin tined flexible oxygen-free copper wires. The signal control carrier line in the cable core is disposed in the inert gas pipe. The current conductors in the cable core are evenly disposed outside the inert gas pipe. The signal control cables are also evenly disposed outside the inert gas pipe. Nonwoven tape is wound on the cable core. The flexible elastomer combined polyvinyl chloride outer sheath is extruded on the tape. The multi-wire combined welding cable typed II is simple and reasonable in structure, advanced in process, and superior in product performance, is high in carrying capacity in operation and wide in operation range, provides power connection and signal connection for operation of automatic welding equipment, and is conducive to implementation of automatic welding.

Owner:江苏霍斯特电气科技有限公司

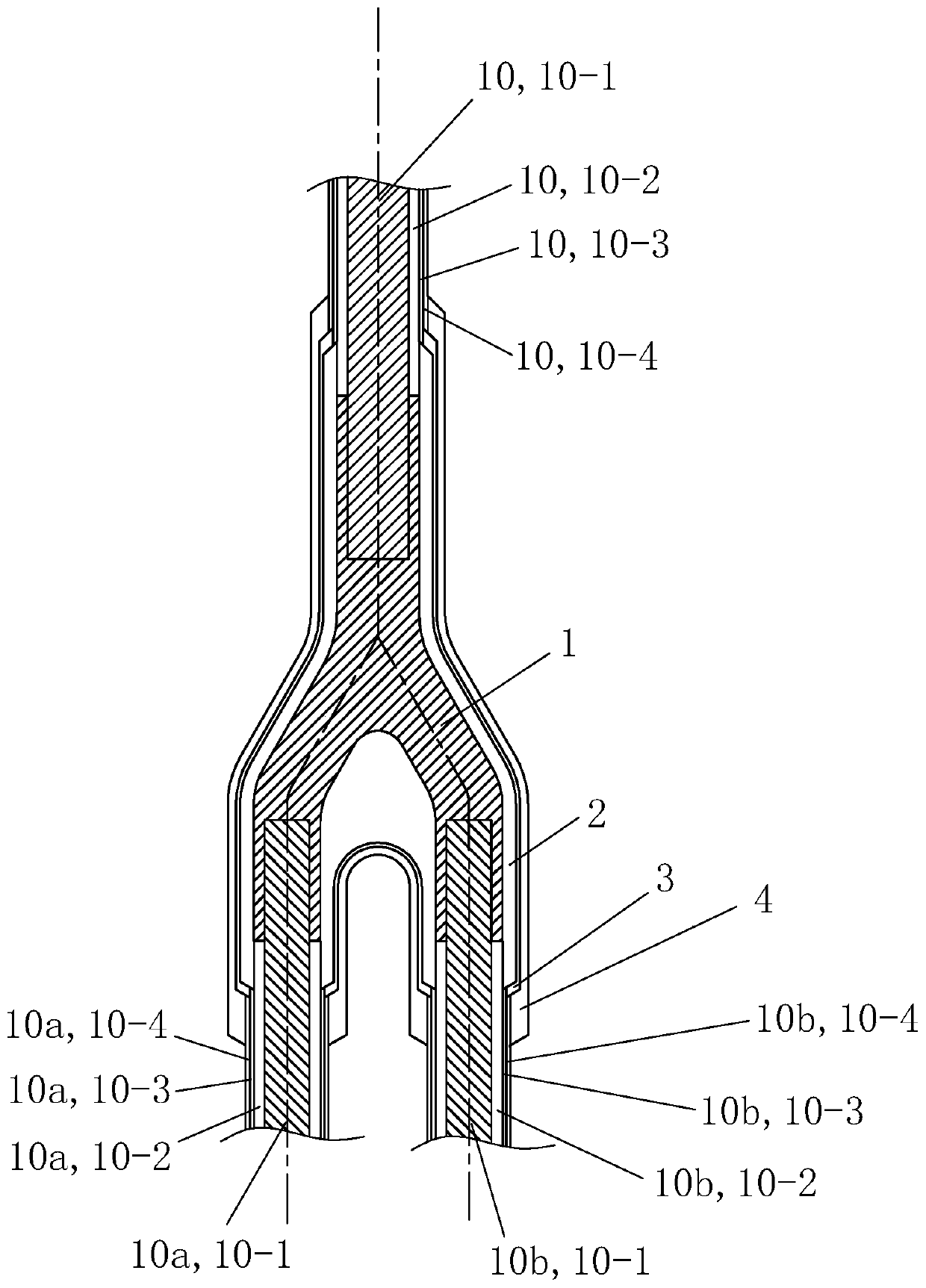

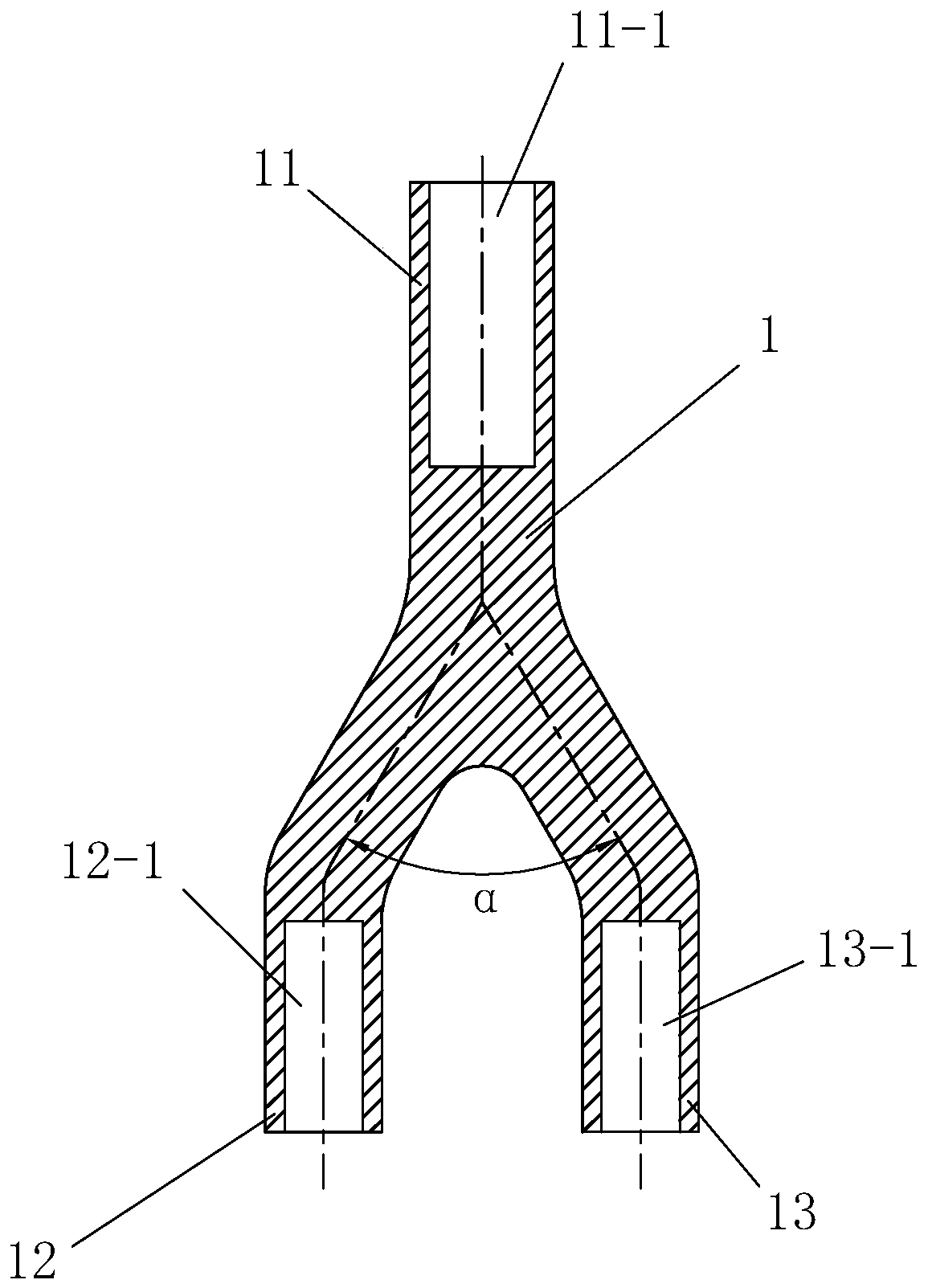

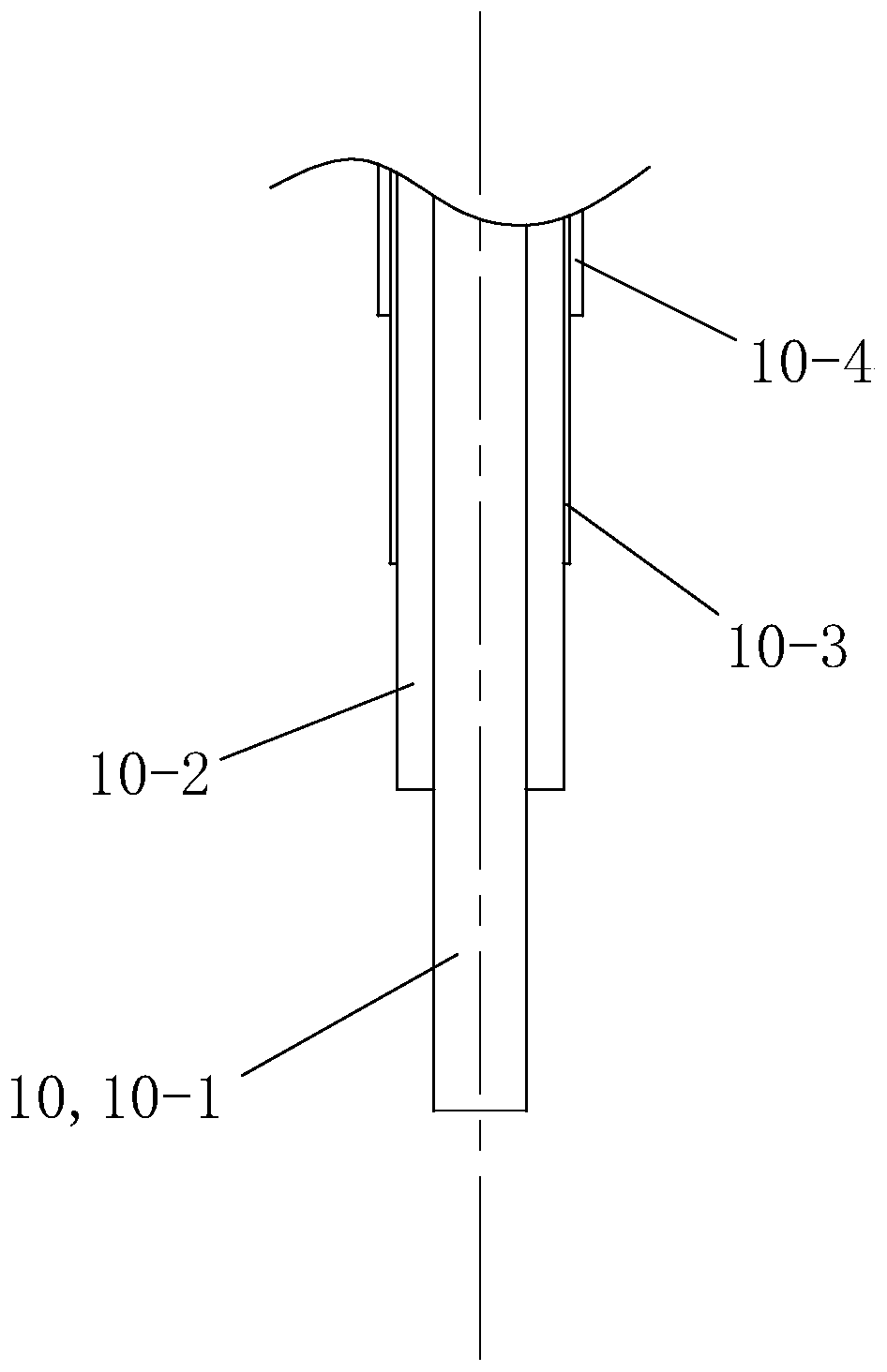

Pre-branched cable and manufacturing method thereof

PendingCN110853804AEliminate tip dischargeAvoid Electric Field DistortionLine/current collector detailsConnections to liquidElectrical conductorElectrical connection

The invention discloses a pre-branched cable which is characterized by comprising a trunk cable, branch cables and a connecting joint. The trunk cable and the branch cables are the same in structure and each comprise a cable conductor, a cable insulating layer, a cable shielding layer and a cable sheath layer. The cross-sectional area of the cable conductor of each branch cable is smaller than that of the cable conductor of the trunk cable. The connecting joint comprises a conductor connecting fitting, a fitting insulating layer, a fitting shielding layer and a fitting sheath layer. The numberof the branch cables is two or three, and each branch cable is fixedly and electrically connected with the trunk cable through the connecting joint. The fitting insulating layer of the connecting joint is connected with the cable insulating layer of each cable into a whole. The fitting shielding layer of the connecting joint is overlapped with the cable shielding layer of each cable in a coveringmanner. The fitting sheath layer of the connecting joint is connected with the cable sheath layer of each cable into a whole.

Owner:CHANGZHOU MARINE CABLE +1

Conductor wire connecting method, and connecting terminal, stator, and rotary electric machine

ActiveUS8153899B2Increase mechanical tensile strengthIncrease crimping degreeConnections effected by permanent deformationCable junctionsElectrical conductorElectric machine

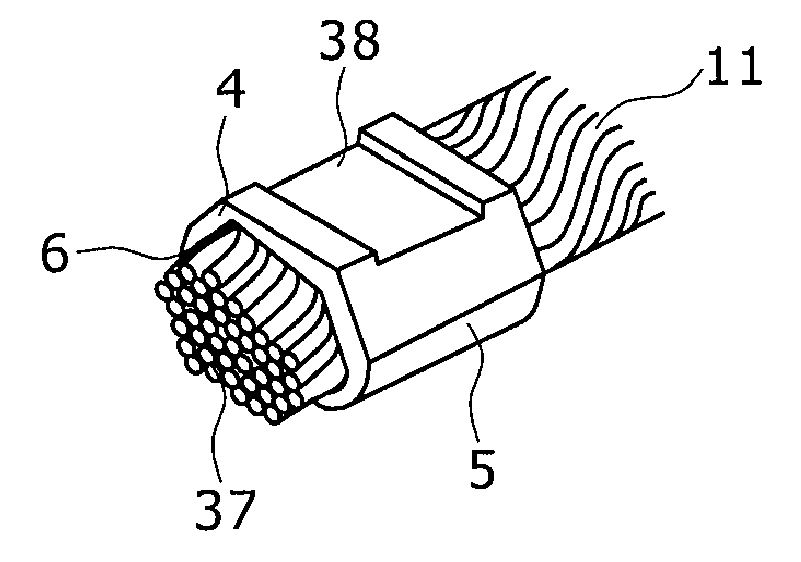

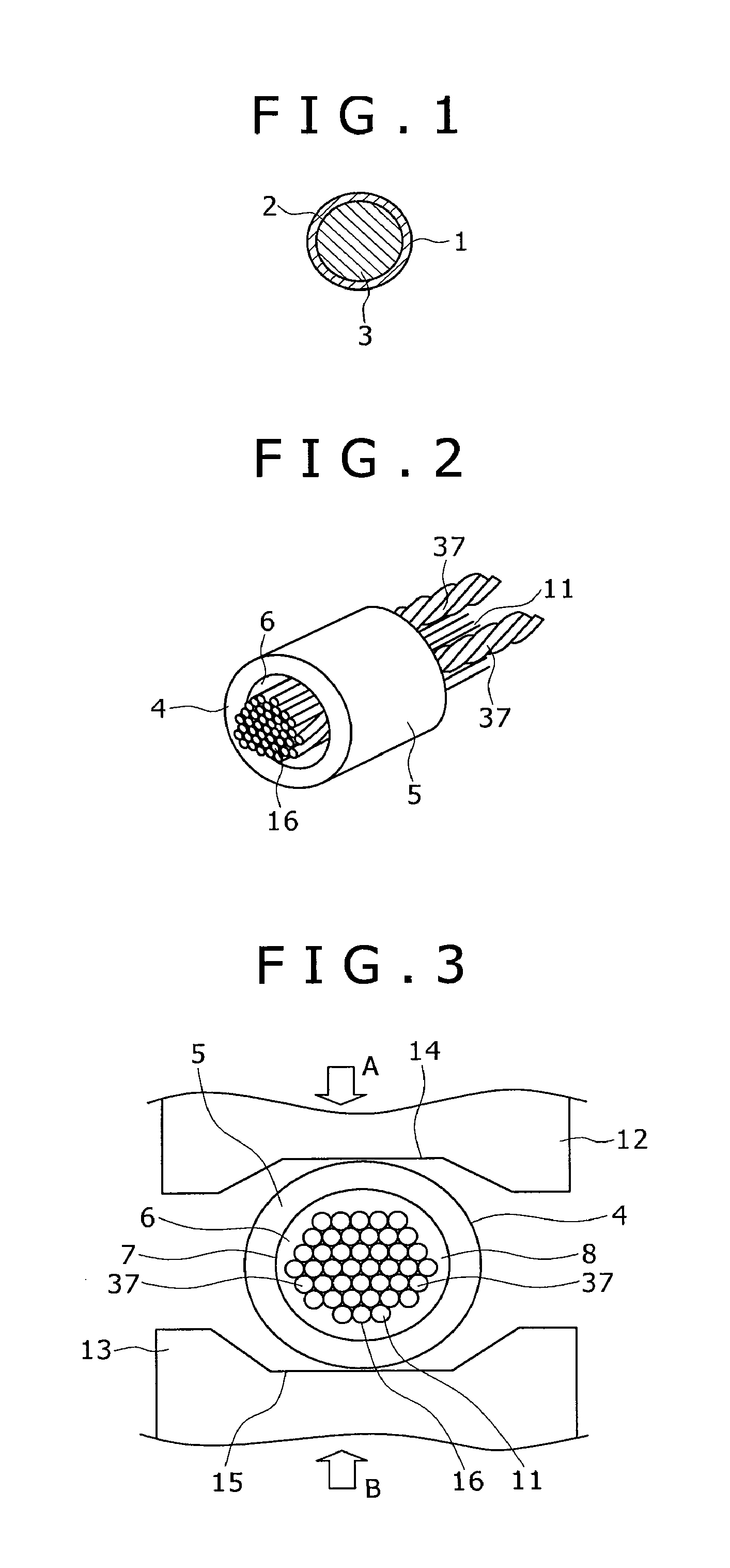

After melted enamel coating is discharged from the crimping connectors, electrical wire-to-wire connection, that is, the fusion process, is carried out inside the crimping connector. In this conductor connection method based on the fusion process, plural the above enamel-coated conductor wires are inserted in the above crimping connector prior to the start of the fusion process. Further, the temporary crimping process which provides the crimping connector a temporary crimping by mechanical pressurizing means is also a part of entire process. Addition of force at both the end parts or either one of them of the cross-section orthogonal to the axis of the above crimping connector may cause expansion, which needs to be suppressed with external fore. At the same time, the areas of cross-section corresponding to both the end parts or either of them mentioned above should preferably be held as small as possible. The above temporary crimping is applied to the above crimping connector for this purpose.

Owner:HITACHI ASTEMO LTD

Preparation method of degradable poly(lactic-co-glycolic acid)

The invention relates to a preparation method of degradable poly(lactic-co-glycolic acid). The preparation method comprises the following steps: 1) dehydrating and refining an industrial lactic acid water solution and glycolic acid as raw materials under vacuum conditions, thus obtaining a lactic-co-glycolic acid oligomer; 2) mixing the lactic-co-glycolic acid oligomer obtained in the step 1) with a catalyst, adding the mixture to a reaction vessel and carrying out heating reaction under vacuum conditions, thus obtaining a poly(lactic-co-glycolic acid) intermediate product; and 3) adding a chain extender MDI to the reaction vessel in the step 2) and carrying out heating reaction under vacuum conditions, thus obtaining high molecular weight poly(lactic-co-glycolic acid).

Owner:桂林市福泰建材有限责任公司

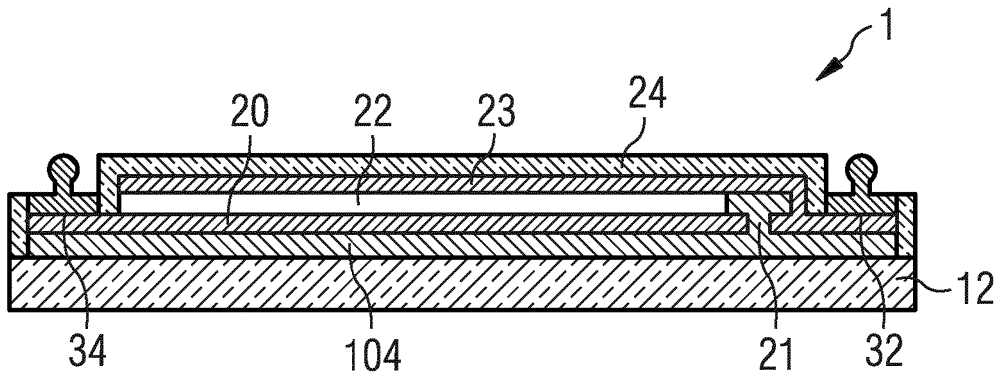

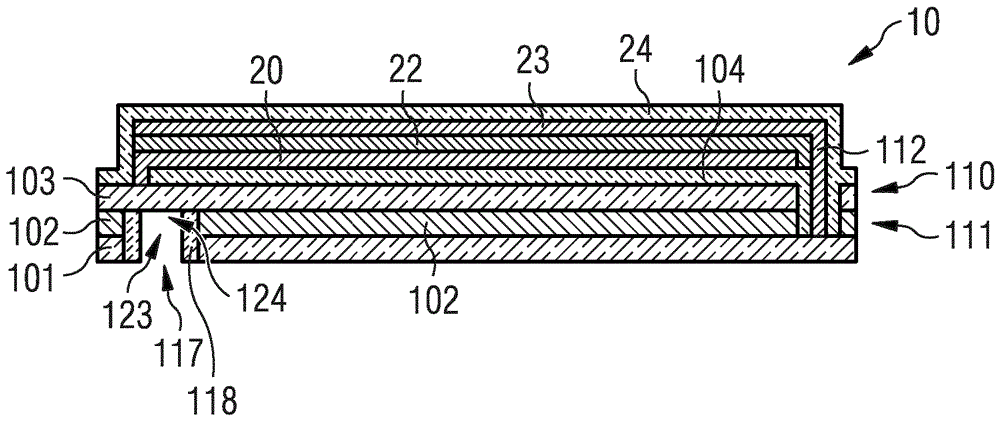

Optoelectronic component and method for producing same

ActiveCN106663744AReduce contact resistanceImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronElectrically conductive

An optoelectronic component (10) and a method for producing same are provided in various exemplary embodiments. The optoelectronic component (10) has a first electrically conductive contact layer (101), an electrically insulating layer (102) over the first electrically conductive contact layer (101), a second electrically conductive contact layer (103) over the electrically insulating layer (102), a first electrically conductive electrode layer (20) over the second electrically conductive contact layer (103), at least one optically functional layer structure (22) over the first electrically conductive electrode layer (20) and a second electrically conductive electrode layer (23) over the optically functional layer structure (22). The second electrically conductive contact layer (103) comprises a first recess (110). The electrically insulating layer (102) comprises a second recess (111) which overlaps the first recess (110). An electrically conductive through-contact (112) is arranged in the first recess (110) and in the second recess (111), said through-contact being guided to the first electrically conductive contact layer (101). The electrically conductive through-contact (112) is electrically insulated with respect to the second electrically conductive contact layer (103).

Owner:OSRAM OLED

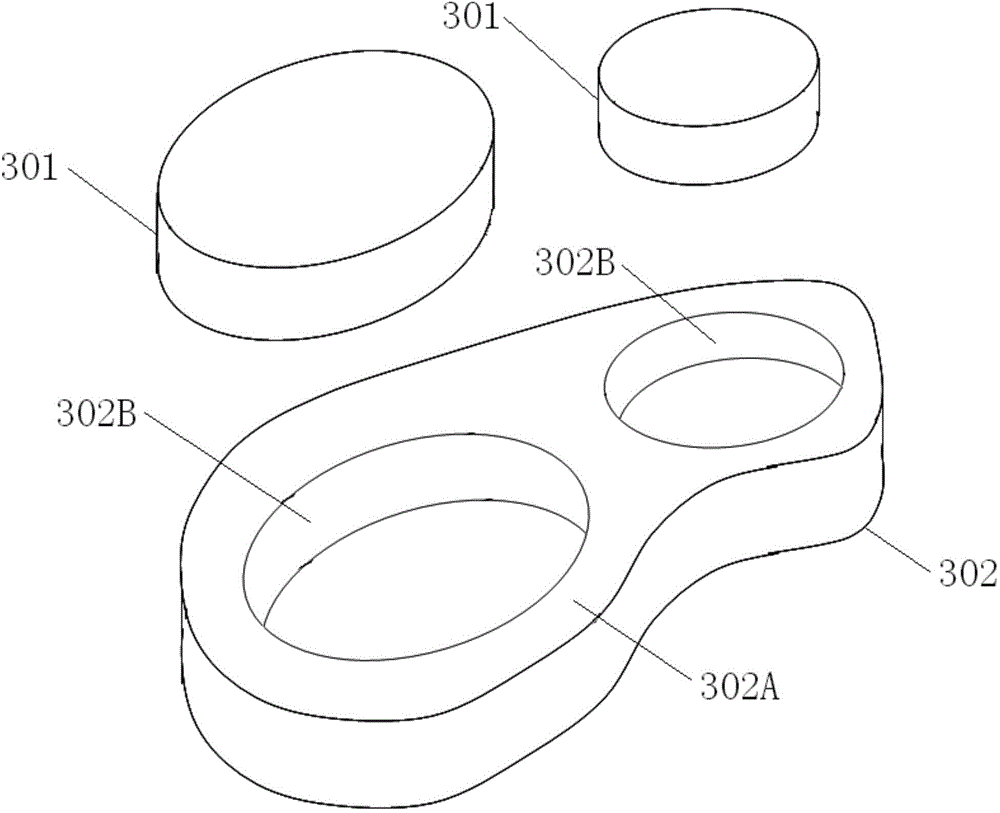

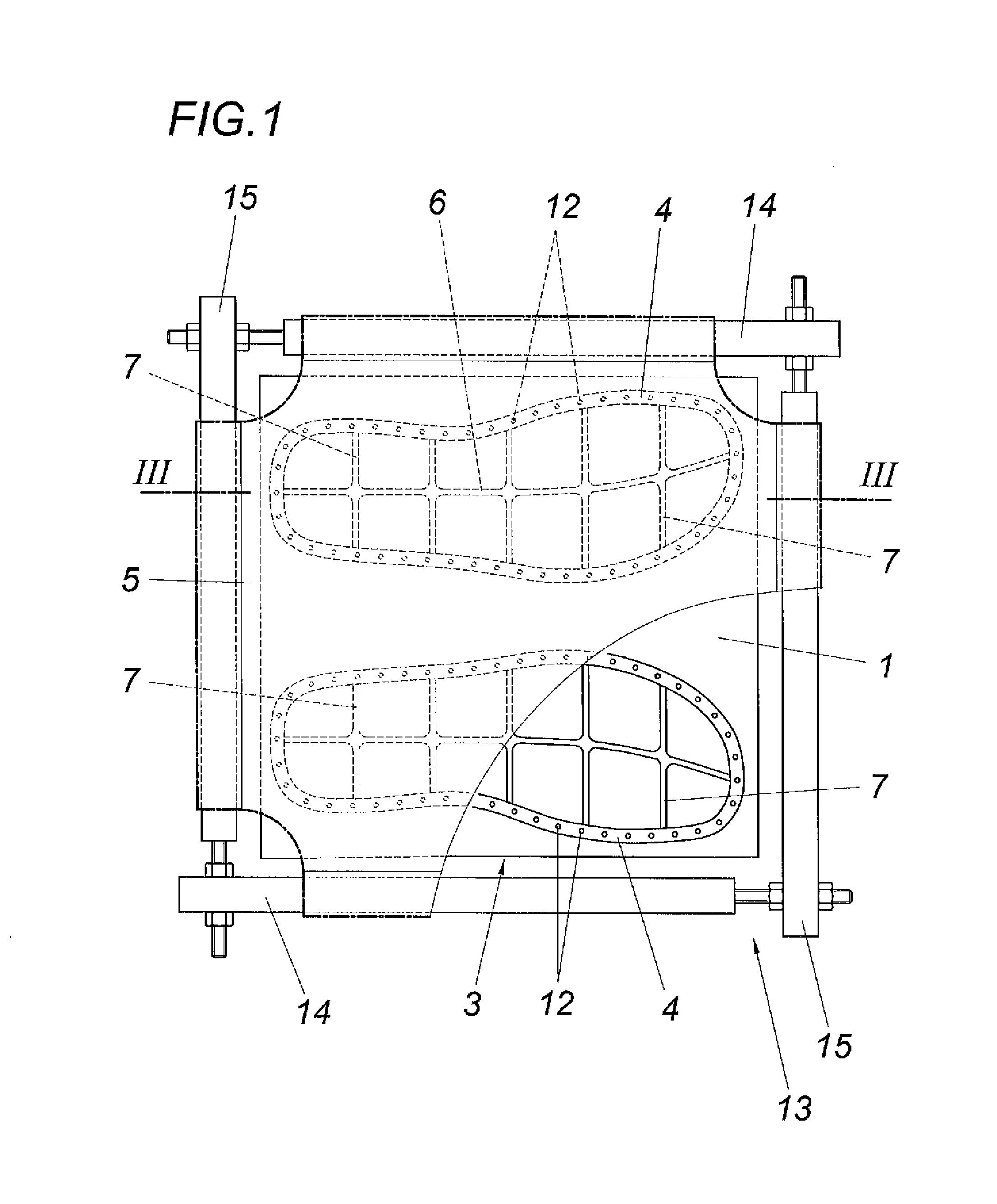

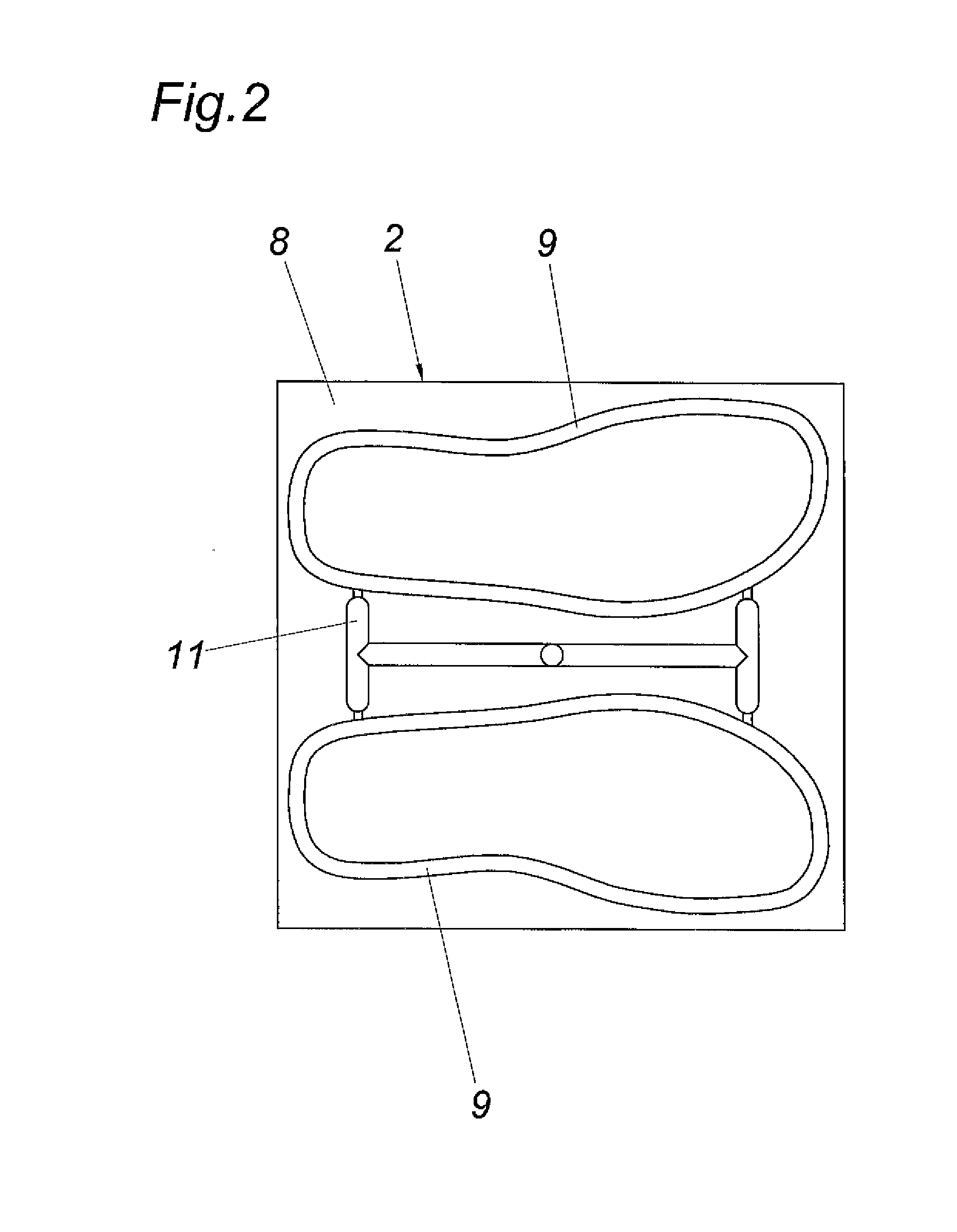

Method and device for producing a footbed for a shoe

InactiveUS20140339730A1Increase mechanical tensile strengthUniform transitionSolesTailstocks/centresEngineeringMechanical engineering

Owner:STOEHR JULIA +1

Method for preparing degradable polylactic acid

The invention relates to a method for preparing degradable polylactic acid. The method includes the steps that firstly, lactic acid serves as the raw material and is dehydrated and refined under the vacuum condition, and lactic acid oligomer is obtained; secondly, the lactic acid oligomer obtained in the first step is mixed with a catalyst, the mixture is added into a reaction container, a heating reaction is conducted under the vacuum condition, and a polylactic acid intermediate product is obtained; thirdly, a chain extender MDI is added to the reaction container in the second step, a heating reaction is conducted under the vacuum condition, and high-molecular-weight polylactic acid is obtained.

Owner:桂林市福泰建材有限责任公司

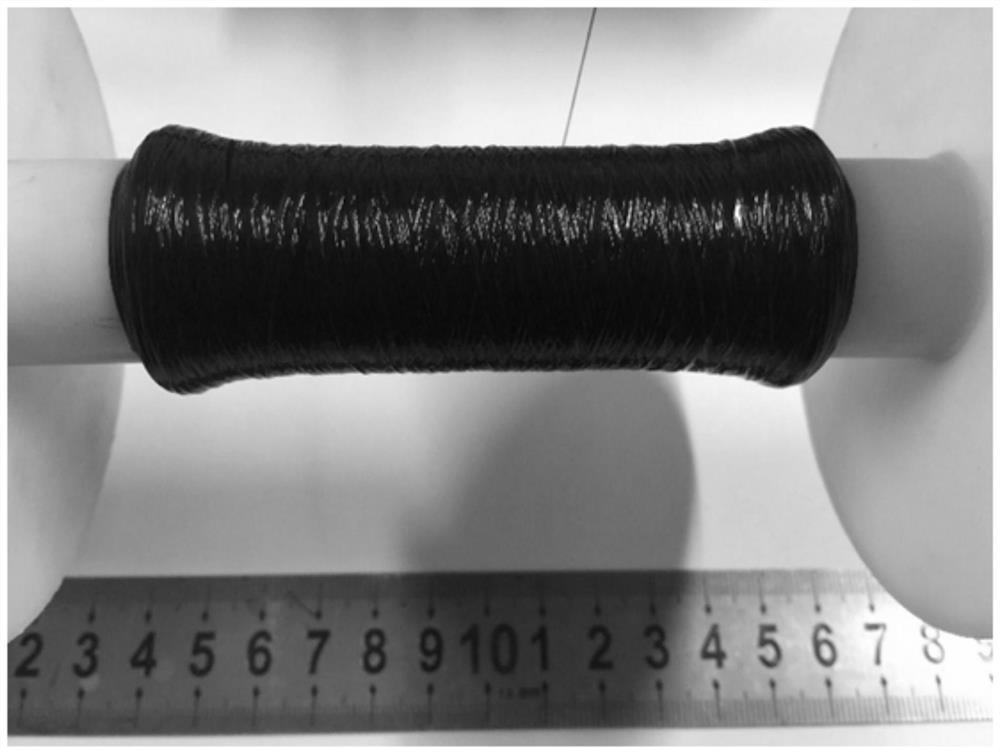

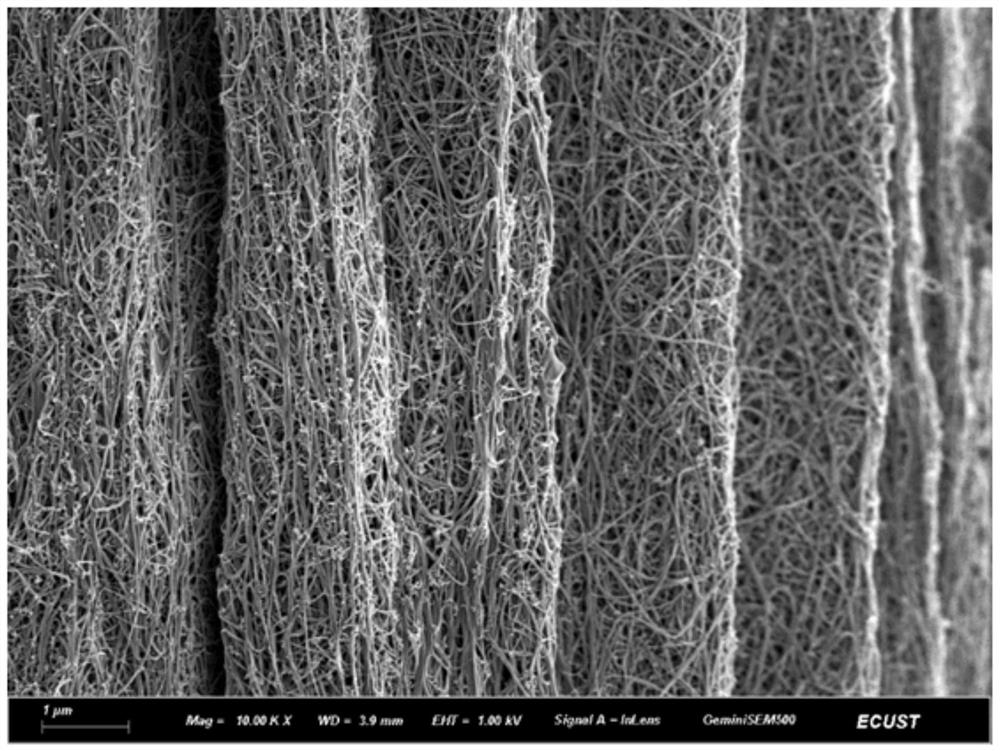

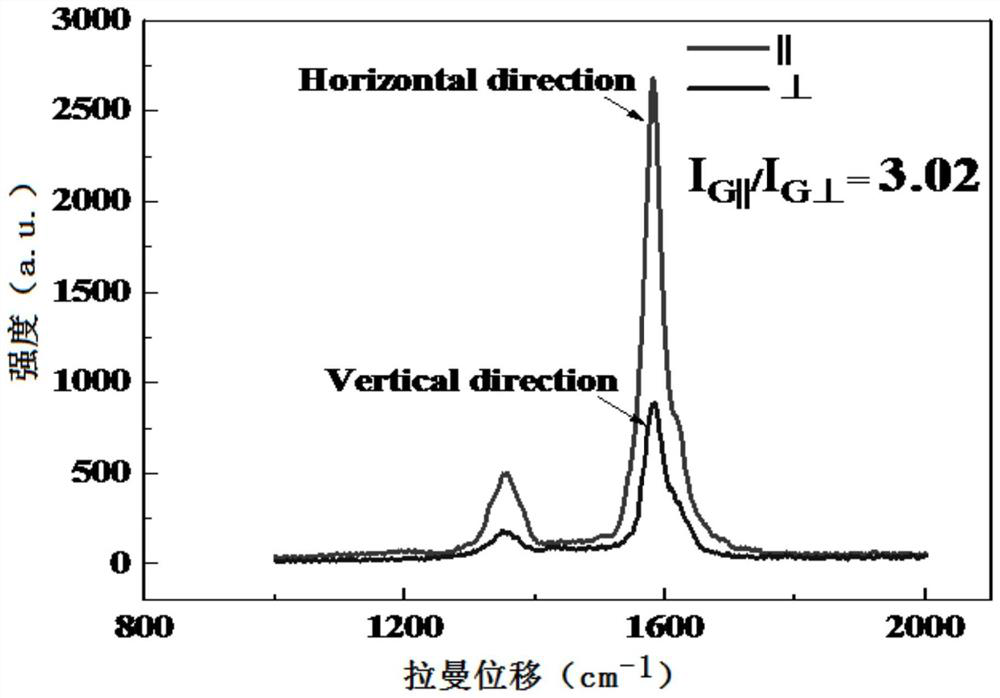

Preparation method of high-oriented carbon nanotube fiber

PendingCN113957568AEasy to controlPotential for industrial mass productionFibre chemical featuresFiberCarbon fibers

The invention discloses a preparation method of high-oriented carbon nanotube fiber. The method can be used for continuously and controllably stretching the carbon nanotube fiber; and the obtained final carbon nanotube fiber has good orientation and excellent mechanical properties, the tensile strength can reach 2.9 GPa, the tensile strength can reach 8.0 GPa after rolling densification, and the toughness is higher than that of carbon fiber. On the premise of not damaging the carbon nanotube fiber, the orientation of the carbon nanotube fiber is improved, and the final tensile strength of the fiber is further improved.

Owner:EAST CHINA UNIV OF SCI & TECH

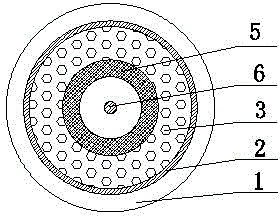

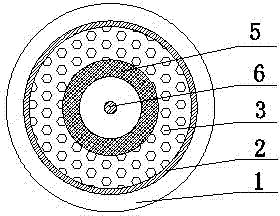

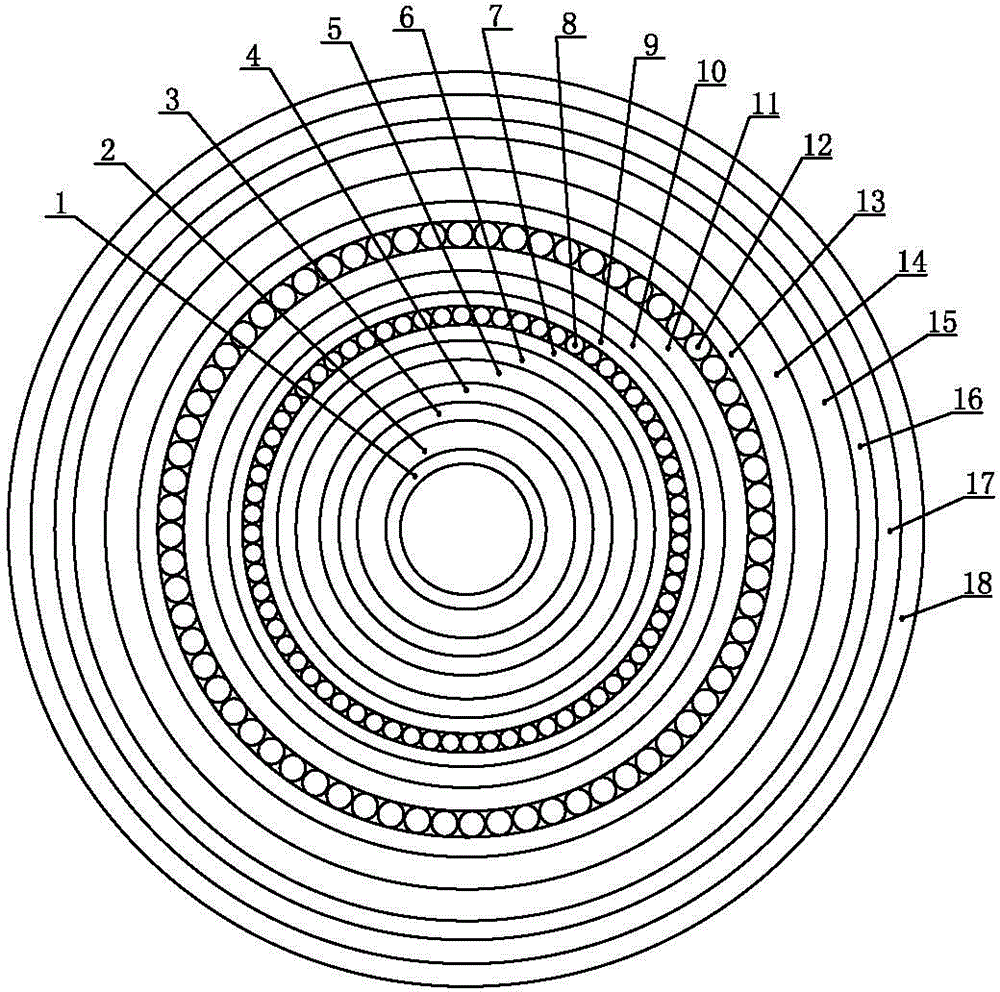

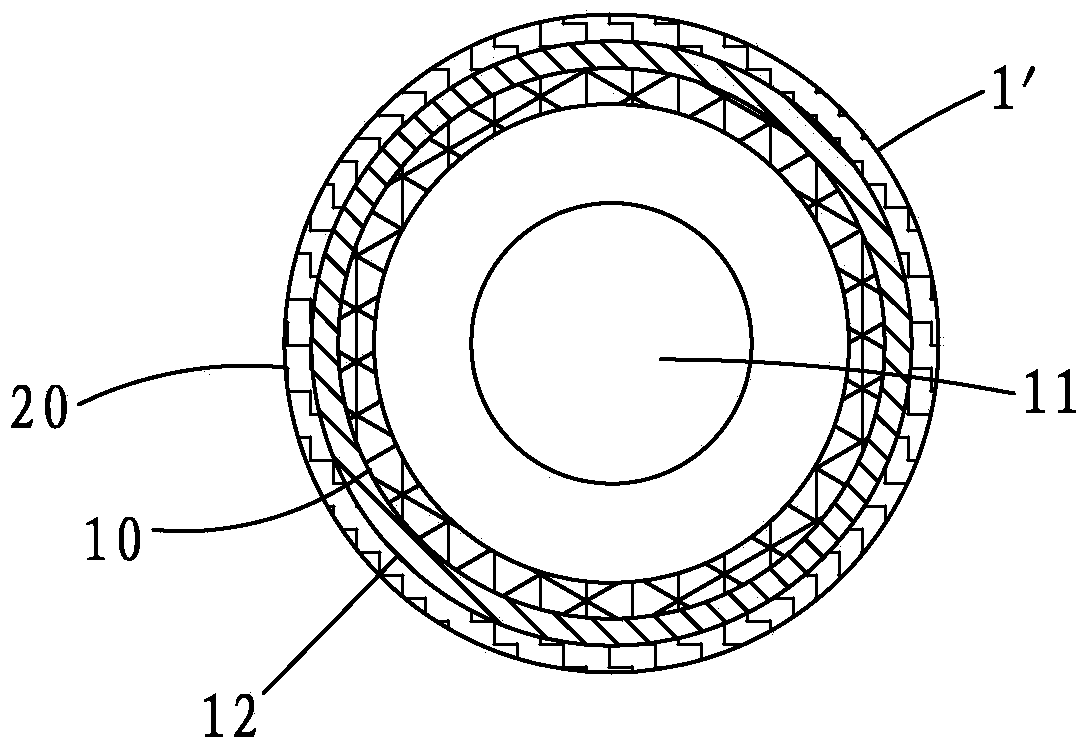

Coaxial cable with compound inner conductor for use in shallow sea bed and manufacturing method thereof

InactiveCN102969073BImprove toughnessEnhanced longitudinal tensile propertiesCoaxial cables/analogue cablesSubmarine cablesPolyesterElectrical conductor

The invention relates to a coaxial cable with a compound inner conductor for use in a shallow sea bed and a manufacturing method thereof. The coaxial cable is characterized in that the inner conductor composed of a plurality of stranded soft round copper wires is wound outside a center conductor, a high pressure polyethylene insulating layer is extruded outside the compound inner conductor; an outer conductor is uniformly woven at the periphery of the high pressure polyethylene insulating layer; two layers of polyester film strips are lapped at the periphery of the outer conductor in opposite directions. and the periphery of the polyester film strip is successively coated with a first asphalt coating layer, a first dipped hemp rope lining layer, a second asphalt coating layer, a copper alloy wire armor layer, a third asphalt coating layer, a second dipped hemp rope lining layer, a fourth asphalt coating layer, a aluminum plated magnesium alloy steel wire armor layer, a fifth asphalt coating layer, a first dipped hemp wrapped strip layer, a sixth asphalt coating layer, a second dipped hemp wrapped strip layer, a seventh asphalt coating layer and a plastic film anti-sticking layer. The cable is stable in structure, good in anti-water-seepage, corrosion-resistant and anti-pulling performances, and stable in signal transmission when water impact occurs.

Owner:JIANGSU YUANYANG DONGZE CABLE

Charging pile cable

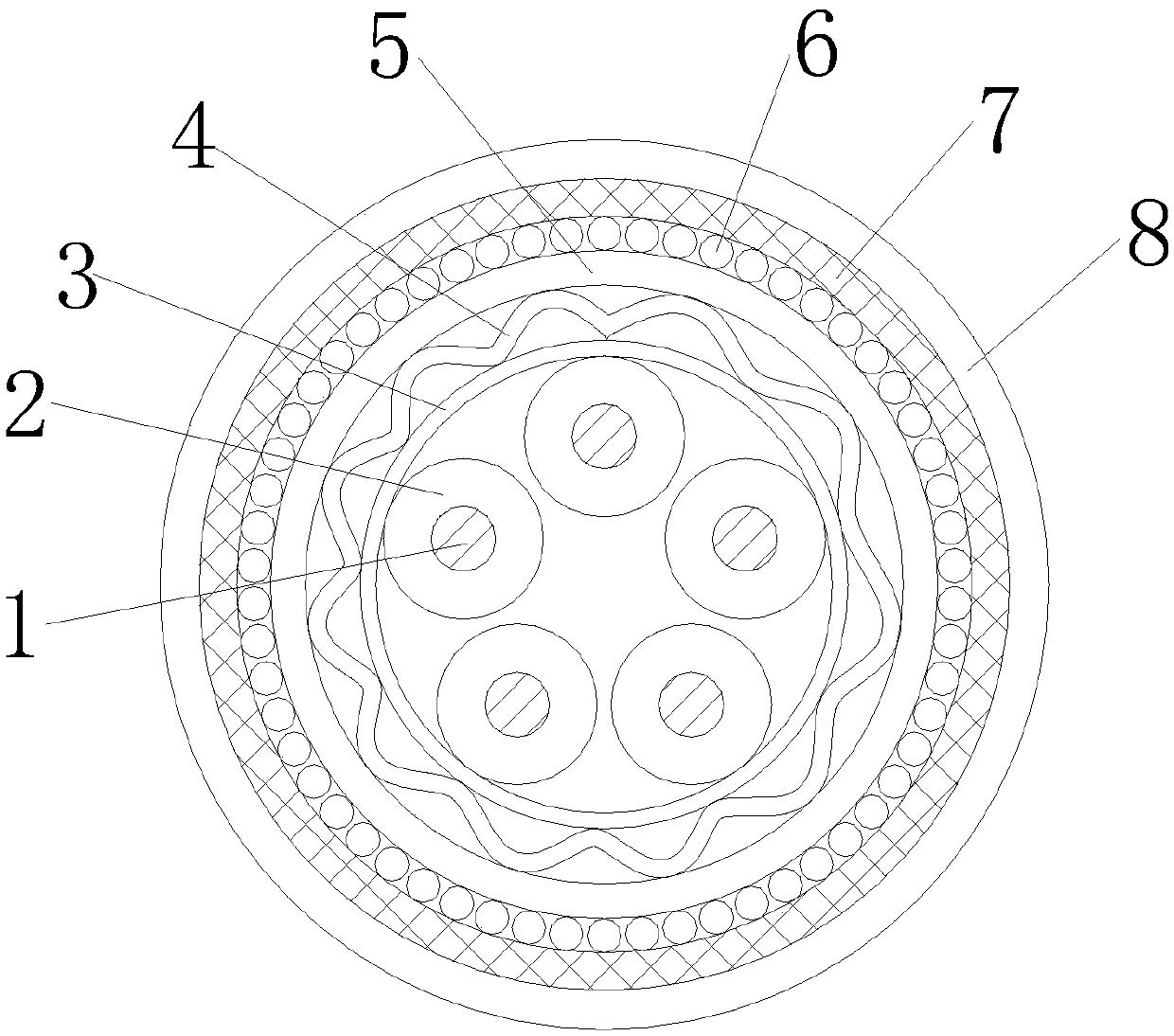

InactiveCN109961886AIncrease mechanical tensile strengthImprove the safety of useInsulated cablesInsulated conductorsCopper wireEngineering

The invention relates to a charging pile cable, which comprises cable cores composed of multiple copper wires and an outer insulating sheath. An inner insulating sleeve is arranged on the outer surface of each cable core. A cable wrapping belt is arranged outside the inner insulating sleeves. An outer insulating sleeve, a return spring sheet, a copper wire armor layer and an aluminum-plastic wovenmesh are arranged in turn between the outer side of the cable wrapping belt and the outer insulating sheath. The outer insulating sleeve, the return spring sheet, the copper wire armor layer and thealuminum-plastic woven mesh are fixedly connected with one another. Under the action of the outer insulating sleeve, a better insulation effect can be achieved, and potential safety hazards are reduced. Through the setting of the return spring sheet, the copper wire armor layer and the aluminum-plastic woven mesh, the mechanical tensile strength of the cable in the construction process can be increased under the action of the return spring sheet, the copper wire armor layer and the aluminum-plastic woven mesh, the use safety of the cable can be improved, and normal operation of equipment can be ensured.

Owner:王蔡浪

Cable reel cable dividing machine

InactiveCN109887664AEnhance resilienceFast replyInsulated cablesInsulated conductorsCopper wirePolyvinyl chloride

The invention relates to a cable reel cable dividing machine. The cable reel cable dividing machine comprises cable cores composed of multiple copper wires and an outer insulating sheath, wherein an inner insulating bush is arranged on the surface of the outer side of each cable core, a cable wrapping tape is arranged at the outer sides of the inner insulating bushes, a restoring spring plate, a polyvinyl chloride bush, a copper wire armored layer and a spring woven net are sequentially arranged between the outer side of the cable wrapping tape and the outer insulating sheath, and the restoring spring plate, the polyvinyl chloride bush, the copper wire armored layer and the spring woven net are fixedly connected respectively. According to the cable reel cable dividing machine, through thearrangement of the restoring spring plate, the restoring force of a cable can be effectively increased under the action of the restoring spring plate, and convenience is brought to quick restoration of the cable; and through the arrangement of the polyvinyl chloride bush, the copper wire armored layer and the spring woven net, the mechanical tensile strength of the cable in the construction process can be effectively enhanced under the actions of the polyvinyl chloride bush, the copper wire armored layer and the spring woven net, the use safety of the cable is improved, and normal work of equipment is ensured.

Owner:周涛

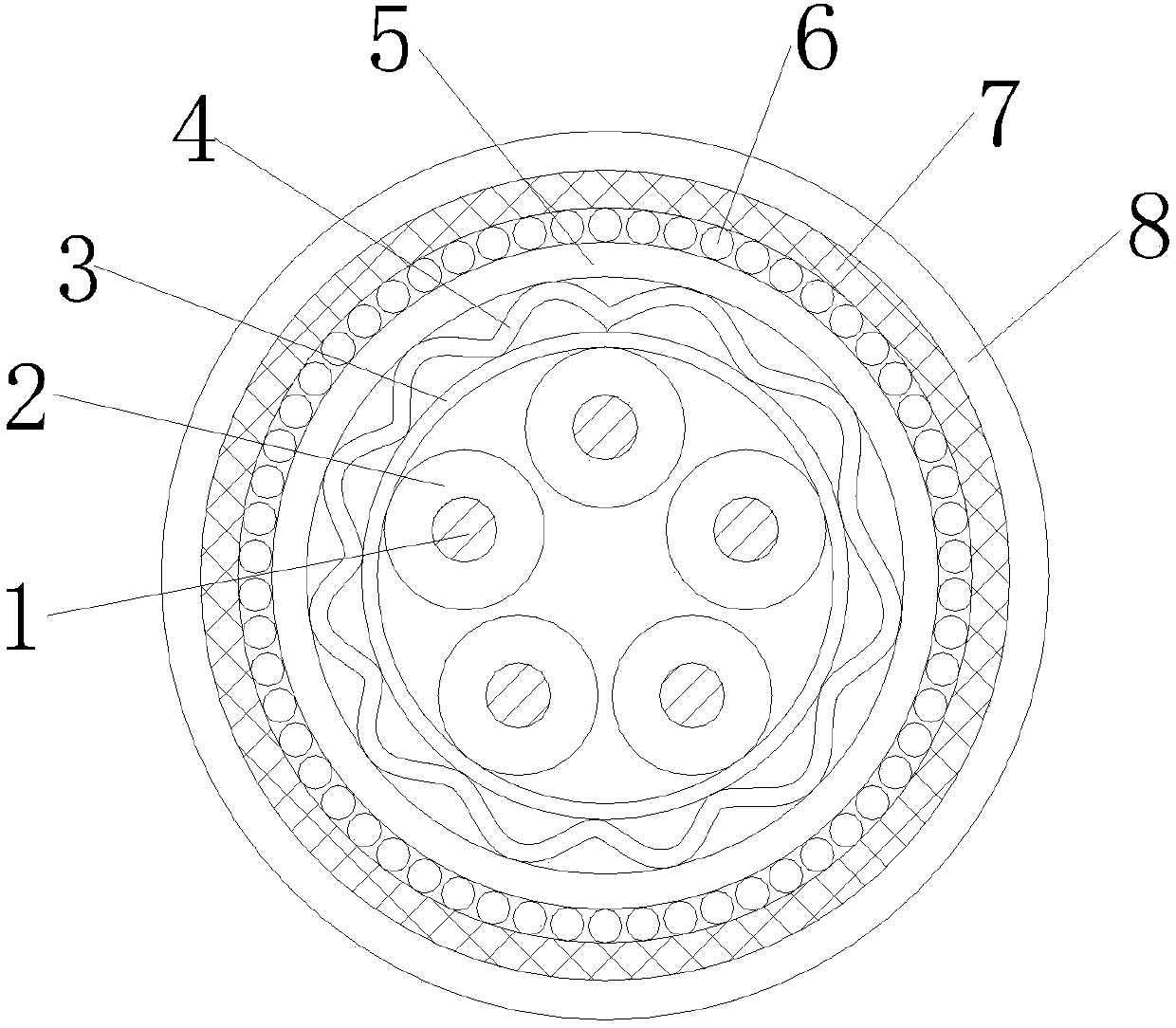

Moisture-proof cable

InactiveCN110491578AEnhance resilienceFast replyInsulated cablesInsulated conductorsCopper wirePolyvinyl chloride

The invention relates to a moistureproof cable. The cable comprises the cable cores composed of a plurality of copper wires and an outer insulating sheath, an inner insulating sleeve is arranged on the outer side surface of each cable core, and a cable wrapping tape is arranged at the outer side of the inner insulating sleeve; a return spring plate, a polyvinyl chloride sleeve, a copper wire armored layer and a spring weaving net are sequentially arranged between the outer side of the cable wrapping tape and the outer insulating sheath, and the return spring plate, the polyvinyl chloride sleeve, the copper wire armor layer and the spring weaving net are fixedly connected. By arranging the return spring plate, the return force of the cable can be effectively improved under the action of thereturn spring plate, and the cable can be conveniently and quickly returned; by arranging the polyvinyl chloride sleeve, the copper wire armor layer and the spring weaving net, the mechanical tensilestrength of the cable in the construction process can be effectively improved under the action of the polyvinyl chloride sleeve, the copper wire armored layer and the spring weaving net, the use safety of the cable is improved, and the normal work of the equipment is ensured.

Owner:何腾

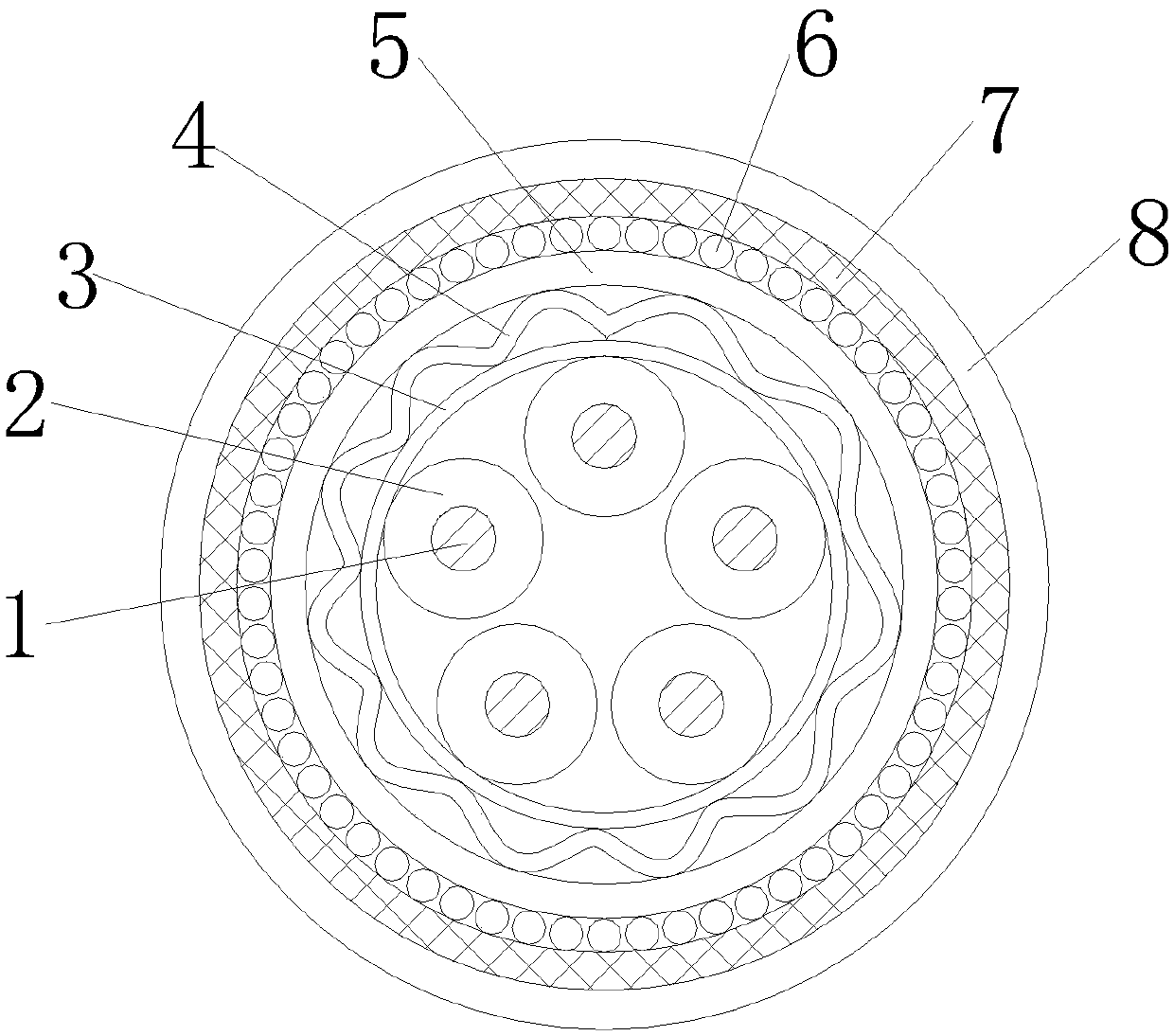

Cable connector

InactiveCN110491576AEnhance resilienceFast replyInsulated cablesInsulated conductorsCopper wirePolyvinyl chloride

The invention relates to a cable connector. A cable used for the cable connector comprises the cable cores composed of a plurality of copper wires and an outer insulating sheath, an inner insulating sleeve is arranged on the outer side surface of each cable core, and a cable wrapping tape is arranged at the outer side of the inner insulating sleeve; a return spring plate, a polyvinyl chloride sleeve, a copper wire armor layer and a spring weaving net are sequentially arranged between the outer side of the cable wrapping tape and the outer insulating sheath, and the return spring plate, the polyvinyl chloride sleeve, the copper wire armor layer and the spring weaving net are fixedly connected. By arranging the return spring plate, the return force of the cable can be effectively improved under the action of the return spring plate, and the cable can be conveniently and quickly returned; by arranging the polyvinyl chloride sleeve, the copper wire armored layer and the spring weaving net,the mechanical tensile strength of the cable during the construction process can be effectively improved under the action of the polyvinyl chloride sleeve, the copper wire armor layer and the springweaving net, the use safety of the cable is improved, and the normal work of the equipment is ensured.

Owner:邓超

New line bridging method and special bridging line

InactiveCN102064498BImprove current carrying capacityIncrease mechanical tensile strengthApparatus for overhead lines/cablesEngineeringElectrical and Electronics engineering

Owner:STATE GRID CORP OF CHINA +1

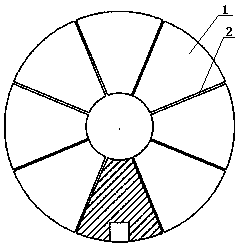

A preparation process of cables for electric vehicle conductive charging system

InactiveCN105355276BGood flexibilityStable structureDetails of conductive coresFlexible cablesInsulation layerElectrical conductor

The invention provides a cable for an electric automobile conduction charging system, and a preparation process thereof. The cable for the charging system is internally provided with seven insulation cores which are twisted to form a beam of twisted cores, the seven insulation cores are respectively two main cores, one ground core, two backup cores, one signal line and one control line, each insulation core comprises one conductor and an insulation layer wrapping the conductor, the signal line and the control line each further comprises a phase-splitting shielding layer, and the phase-splitting shielding layers wrap the insulation layers; and the external layer of the twisted cores is successively extruded by an inner sheath layer, a total shielding layer and an oversheath layer. The product provided by the invention has the advantages of quite high mechanical tensile strength, wear resistance, corrosion resistance, interference immunity, flexibility, reciprocating bendability, low-transfer impedance, vehicle rolling resistance, high appearance roundness, low production cost and the like.

Owner:福建锦鸿线缆有限公司

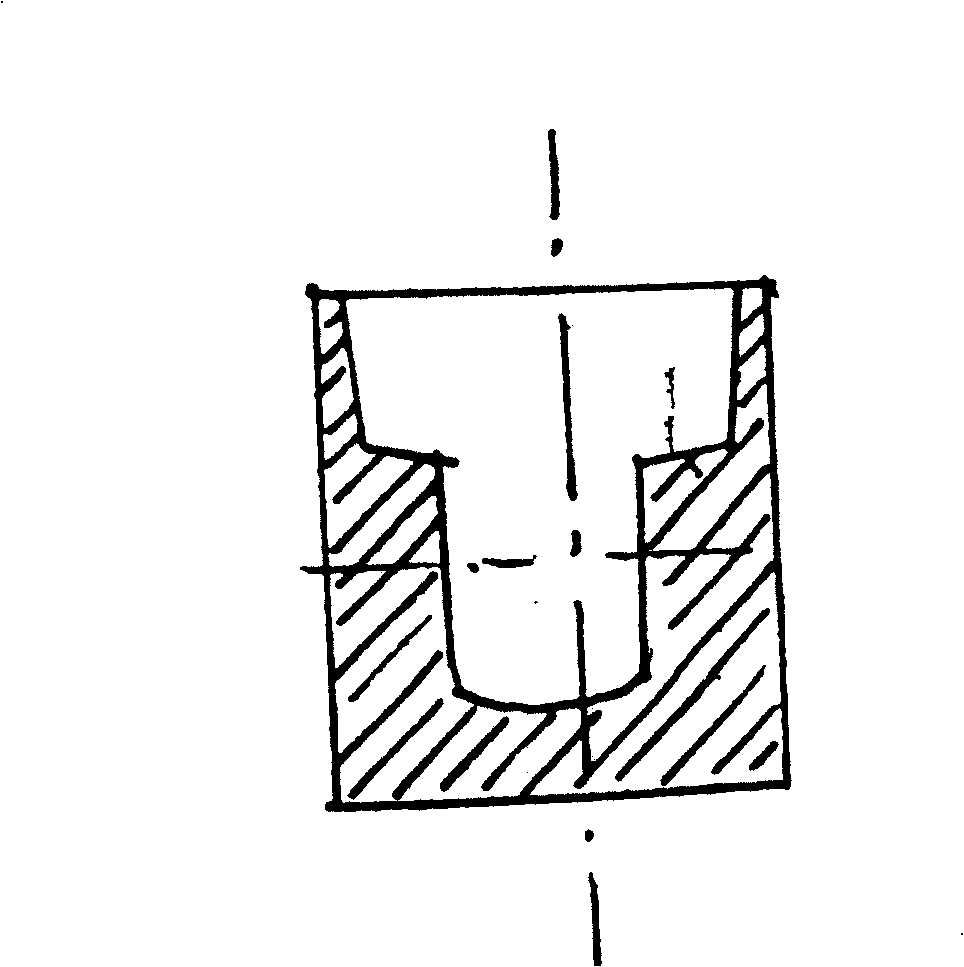

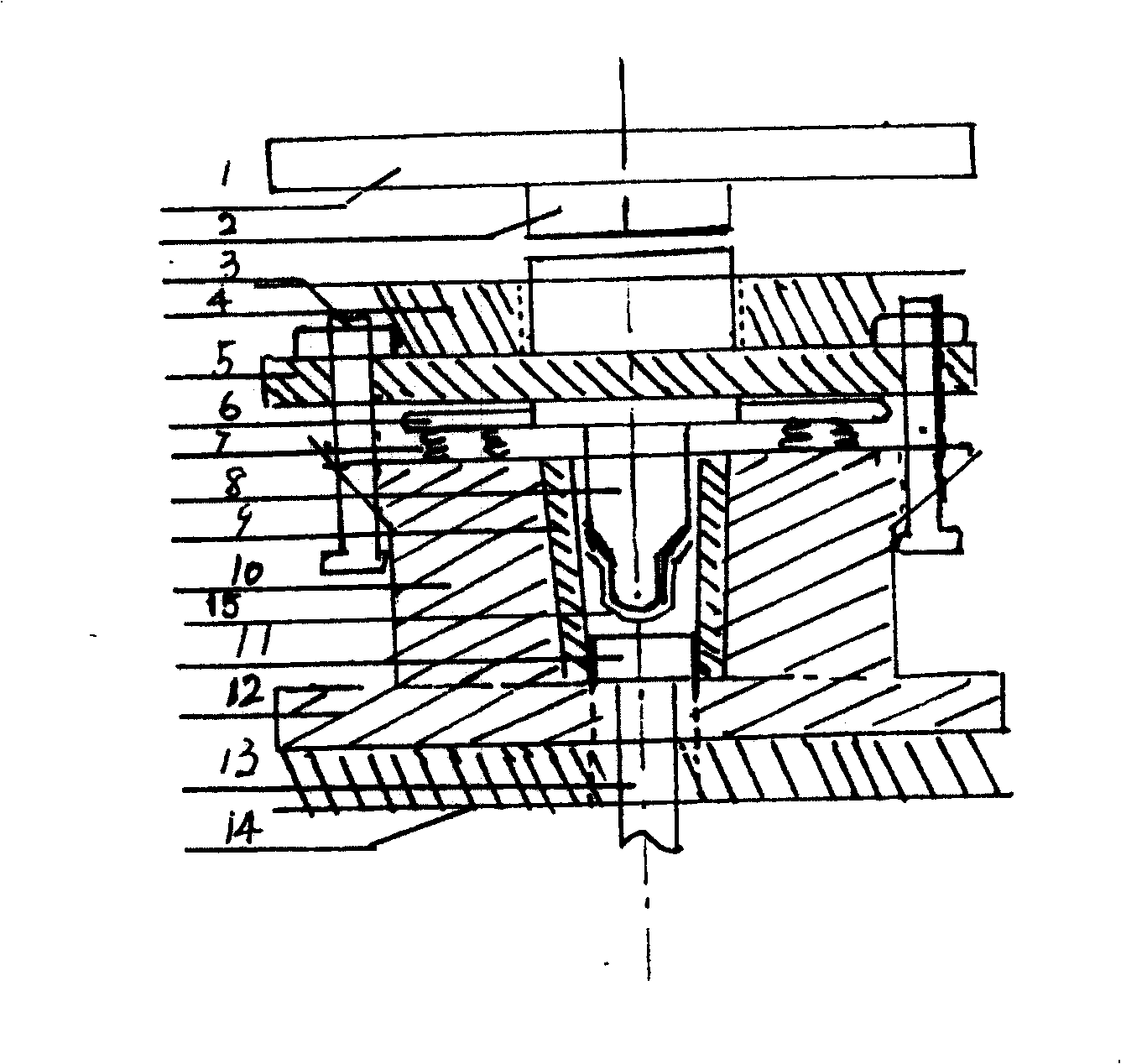

Liquid state forging die method manufactured automobile air compressor piston and its manufacturing technology

InactiveCN100429400CImprove mechanical propertiesImprove thermal stabilityPositive displacement pump componentsPlungersManufacturing technologyLiquid state

The present invention relates to an automobile compressor piston, including piston pin seat. It is characterized by that side surface of said piston pin seat is made into the form of flat block, the skirt inner cavity is hollow cavity. The die equipment for making automobile compressor piston is formed from convex core for forming piston inner cavity, discharging ring, female die for forming exterior form of the piston and bottom die.

Owner:孙前程

Production of powder cementing agent for glass bat

InactiveCN1220744CHigh solid contentGood adhesion and cohesionEster polymer adhesivesNon-woven fabricsContinuous productionFiber

A method of preparing powdery bonding material for blankets of glass precursor fibers. It comprises, introducing anion polymeric emulsifying agent, preparing polymer emulsion with high content of solids, low viscosity and high stability by core-sheath polymerization, then obtaining powdery bonding material. The product has excellent bonding ability and cohesion, effectively improves mechanical pulling strength of glass precursor fiber.

Owner:南京彤天广元高分子材料有限公司

A method for preparing dry pu/pvdf hydrophobic polyurethane coating for synthetic leather

InactiveCN103882726BImprove hydrophobicityImprove anti-pollution performanceSynthetic resin layered productsLaminationPolymer scienceOrganosolv

The invention discloses a method for preparing a dry-process PU / PVDF (polyurethane / polyvinylidene fluoride) hydrophobic polyurethane coating for synthetic leather. The method comprises the following steps: (1) mixing PU with PVDF; (2) adding an organic solvent with N,N-dimethylformamide (DMF) and methyl ethyl ketone (MEK) in a mass ratio of (0-50): (0-20), adding a color paste aid to prepare a surface layer, preparing a bonding layer in a ratio of PU to DMF to MEK to color paste of (0-100): (0-50): (0-20): (0-15), and fully stirring slurry of the surface layer and a surface material of the bonding layer by a vacuum mixer at room temperature respectively to form viscous solution slurry; and (3) applying a dry-process surface layer coating to release paper, solidifying for forming to obtain a dry-process PU / PVDF surface layer, applying the bonding layer to the surface layer, bonding a wet-process base material of the synthetic leather with the dry-process surface layer by a semi-dry bonding method, and drying and curing to obtain the dry-process PU / PVDF hydrophobic polyurethane coating. After PU / PVDF blending modification, the coating is high in hydrophobicity, pollution resistance, flame retardance coefficient and mechanical tensile strength; the method is simple, low in requirement and low in cost and facilitates industrialization production application of the synthetic leather.

Owner:SHAANXI UNIV OF SCI & TECH +1

Charging pile cable

InactiveCN109887643AIncrease mechanical tensile strengthImprove the safety of usePlastic/resin/waxes insulatorsInsulated cablesCopper wireCopper

The invention relates to a charging pile cable. The charging pile cable comprises cable cores composed of multiple copper wires and an outer insulating sheath, wherein an inner insulating bush is arranged on the outer side surface of each cable core, a cable wrapping tape is arranged at the outer sides of the inner insulating bushes, an outer insulating bush, a restoring leaf spring, a copper wirearmored layer and an aluminum-plastic woven net are sequentially arranged between the outer side of the cable wrapping tape and the outer insulating sheath, and the outer insulating bush, the restoring leaf spring, the copper wire armored layer and the aluminum-plastic woven net are fixedly connected respectively. According to the charging pile cable, a good insulation effect can be effectively achieved under the action of the outer insulating bush, and the potential safety hazard is lowered; and through the arrangement of the restoring leaf spring, the copper wire armored layer and the aluminum-plastic woven net, the mechanical tensile strength of the cable in the construction process can be effectively enhanced under the actions of the restoring leaf spring, the copper wire armored layer and the aluminum-plastic woven net, the use safety of the cable is improved, and normal work of equipment is ensured.

Owner:周涛

Composite insulator fitting buckle crimping die and its crimping process

ActiveCN104299736BSimple crimping processReasonable structureInsulatorsMechanical stretchingComposite insulators

The invention discloses a composite insulator hardware pressing die. The composite insulator hardware pressing die comprises a pre-pressing die body and a secondary pressing die body, wherein the pre-pressing die body and the secondary pressing die body are not concentric, the pre-pressing die body and the secondary pressing die body are each formed by arranging multiple die body blocks in the circumferential direction, and a gap is reserved between every two adjacent die body blocks. The invention further discloses a pressure welding technology of composite insulator hardware. According to the pressure welding technology of the composite insulator hardware, primary pressure welding and secondary pressure welding are conducted, the pre-pressing die body is installed on a primary pressing machine, one end of the pre-pressing die body is tightly attached to the encapsulated end of the hardware during pre-pressing of the hardware, and then pre-pressing pressure welding is conducted; encapsulated hardware which is obtained through injection molding is placed on the secondary pressing die body, one end of the secondary pressing die body is close to the encapsulated end of the hardware, then secondary pressing is conducted on a first section, and then pressing is conducted on other sections behind the first section in sequence. The composite insulator hardware pressing die is reasonable in structure, the pressing technology is simple, and stress of the pressed surface of the hardware is even; compared with a traditional pressing technology, the area of the pressed surface of the hardware is effectively increased, the mechanical tensile strength of a composite insulator is improved, and safe operation of the composite insulator is guaranteed.

Owner:STATE GRID CORP OF CHINA +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com