Preparation method of high-oriented carbon nanotube fiber

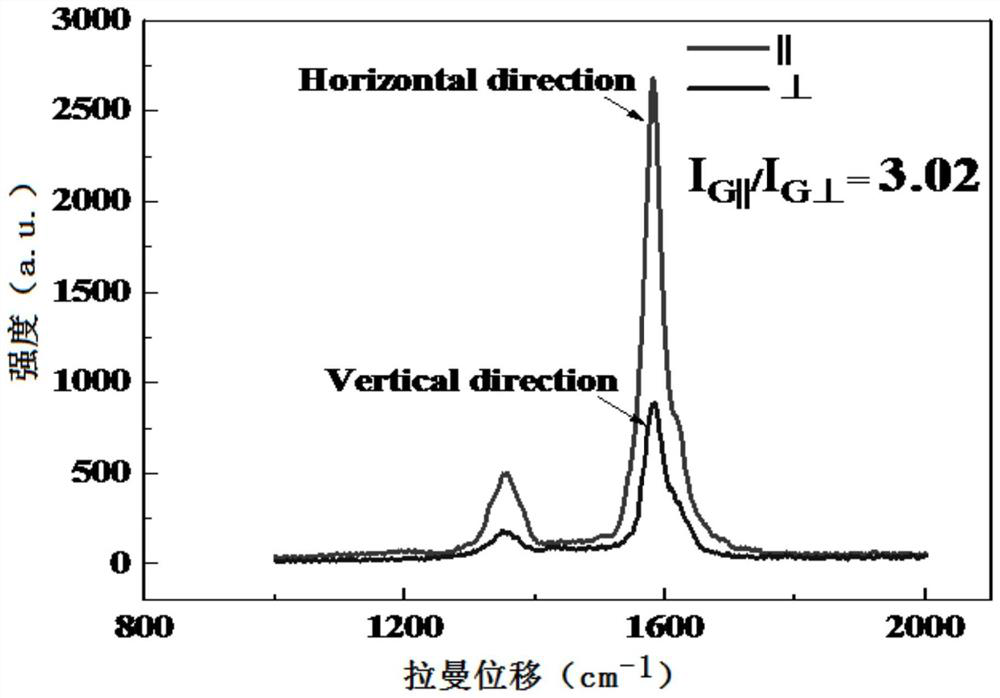

A technology of carbon nanotube fibers and carbon nanotubes, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of cumbersome process and limit the application and development of carbon nanotube fibers, achieve good fiber orientation, improve final resistance Tensile strength, effect of improving orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

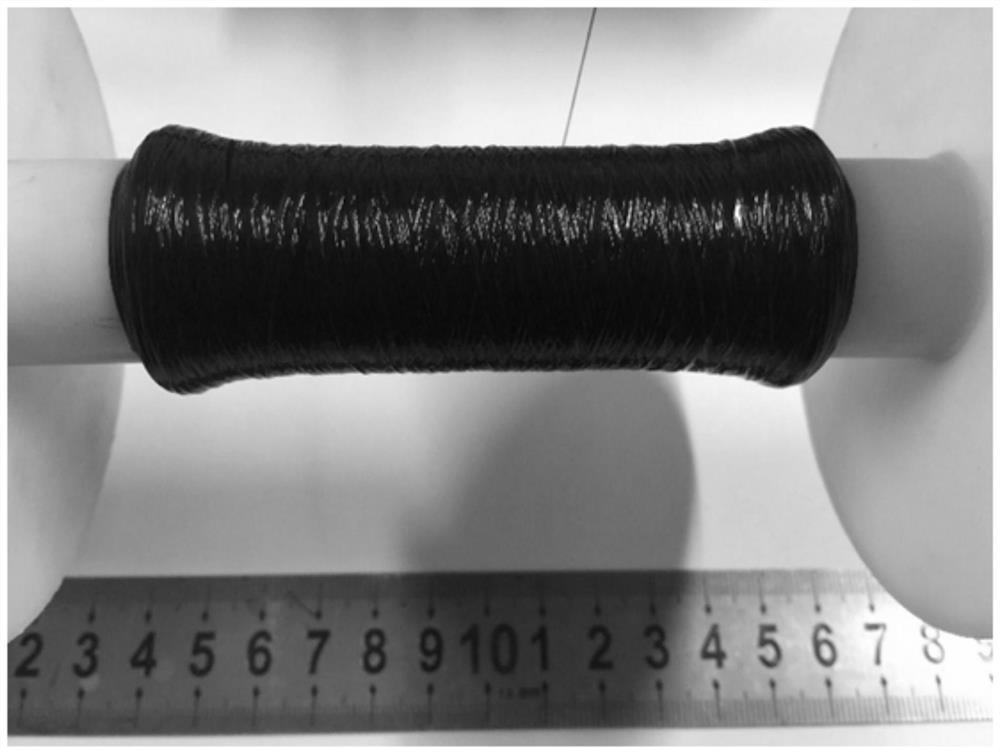

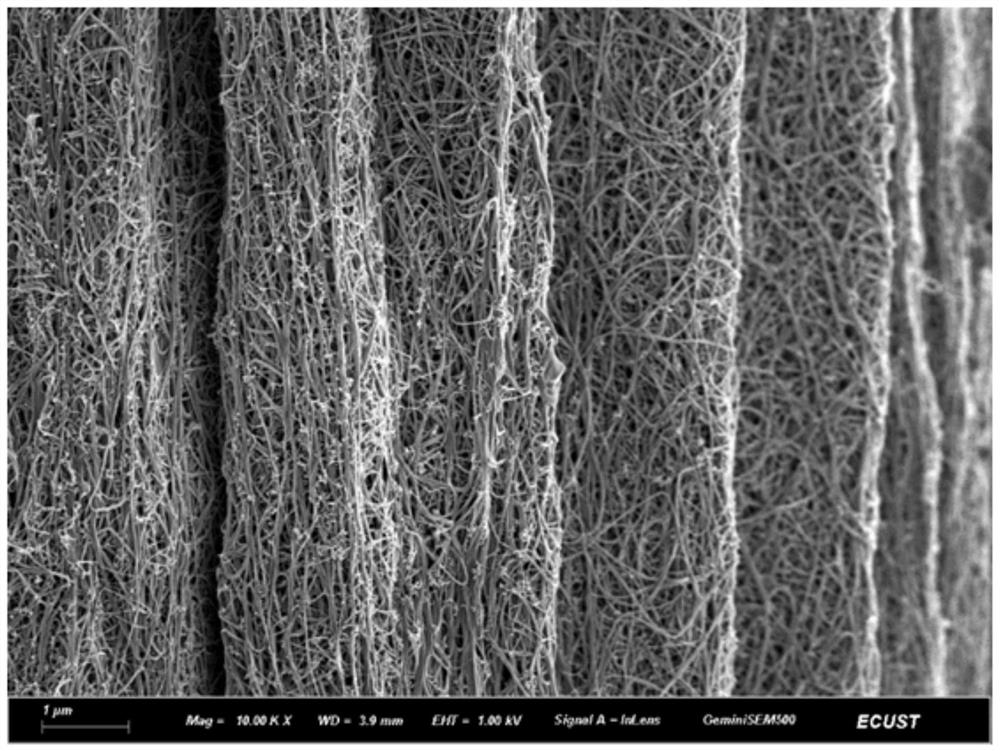

[0040] A preparation method of highly oriented carbon nanotube fibers, comprising the following steps:

[0041] An ethanol solution containing 2.0 wt.% ferrocene and an ethanol solution containing 0.5 wt.% thiophene were respectively prepared in an Erlenmeyer flask, and were uniformly mixed by ultrasonication. Use the liquid supply pump to feed the above-mentioned ferrocene and thiophene solution at 200ml min -1 The flow rate is injected into a horizontal tubular high-temperature furnace (SGL-1200 from Shanghai Experimental Electric Furnace Co., Ltd.), the furnace temperature is 1300°C, and the nitrogen flow rate is 100L h -1 , in a high temperature environment (1300°C), the catalyst (ferrocene), carbon source (ethanol) and growth promoter (thiophene) interact to continuously generate carbon nanotubes and self-assemble into carbon nanotube macroscopic cylinders, and then follow The carrier gas is continuously blown out of the furnace tube, and the inner diameter of the cerami...

Embodiment 2

[0051] A preparation method of highly oriented carbon nanotube fibers, comprising the following steps:

[0052] An ethanol solution containing 2.0 wt.% ferrocene and an ethanol solution containing 0.5 wt.% thiophene were respectively prepared in an Erlenmeyer flask, and were uniformly mixed by ultrasonication. Use the liquid supply pump to feed the above-mentioned ferrocene and thiophene solution at 200ml min -1 The flow rate is injected into a horizontal tubular high-temperature furnace, the furnace temperature is 1300°C, and the nitrogen flow rate is 100L h -1 , in a high temperature environment (1300°C), the catalyst (ferrocene), carbon source (ethanol) and growth promoter (thiophene) interact to continuously generate carbon nanotubes and self-assemble into carbon nanotube macroscopic cylinders, and then follow The carrier gas is continuously blown out of the furnace tube, and the inner diameter of the ceramic tube is 60mm.

[0053] The macroscopic cylinder of carbon nano...

Embodiment 3

[0058] A preparation method of highly oriented carbon nanotube fibers, comprising the following steps:

[0059] An ethanol solution containing 2.0 wt.% ferrocene and an ethanol solution containing 0.5 wt.% thiophene were respectively prepared in an Erlenmeyer flask, and were uniformly mixed by ultrasonication. Use the liquid supply pump to feed the above-mentioned ferrocene and thiophene solution at 200ml min -1 The flow rate is injected into a vertical tubular high-temperature furnace (SX2-1200 from Shanghai Experimental Electric Furnace Company), the furnace temperature is 1300°C, and the nitrogen flow rate is 100L h -1 , in a high temperature environment (1300°C), the catalyst (ferrocene), carbon source (ethanol) and growth promoter (thiophene) interact to continuously generate carbon nanotubes and self-assemble into carbon nanotube macroscopic cylinders, and then follow The carrier gas is continuously blown out of the furnace tube, and the inner diameter of the ceramic tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com