Pre-branched cable and manufacturing method thereof

A branch cable and pre-branch technology, which is applied in the field of power cables, can solve the problems of increased ship weight, heavy laying workload, and troublesome laying, and achieve the effects of meeting electromagnetic compatibility requirements, high use safety, and eliminating tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

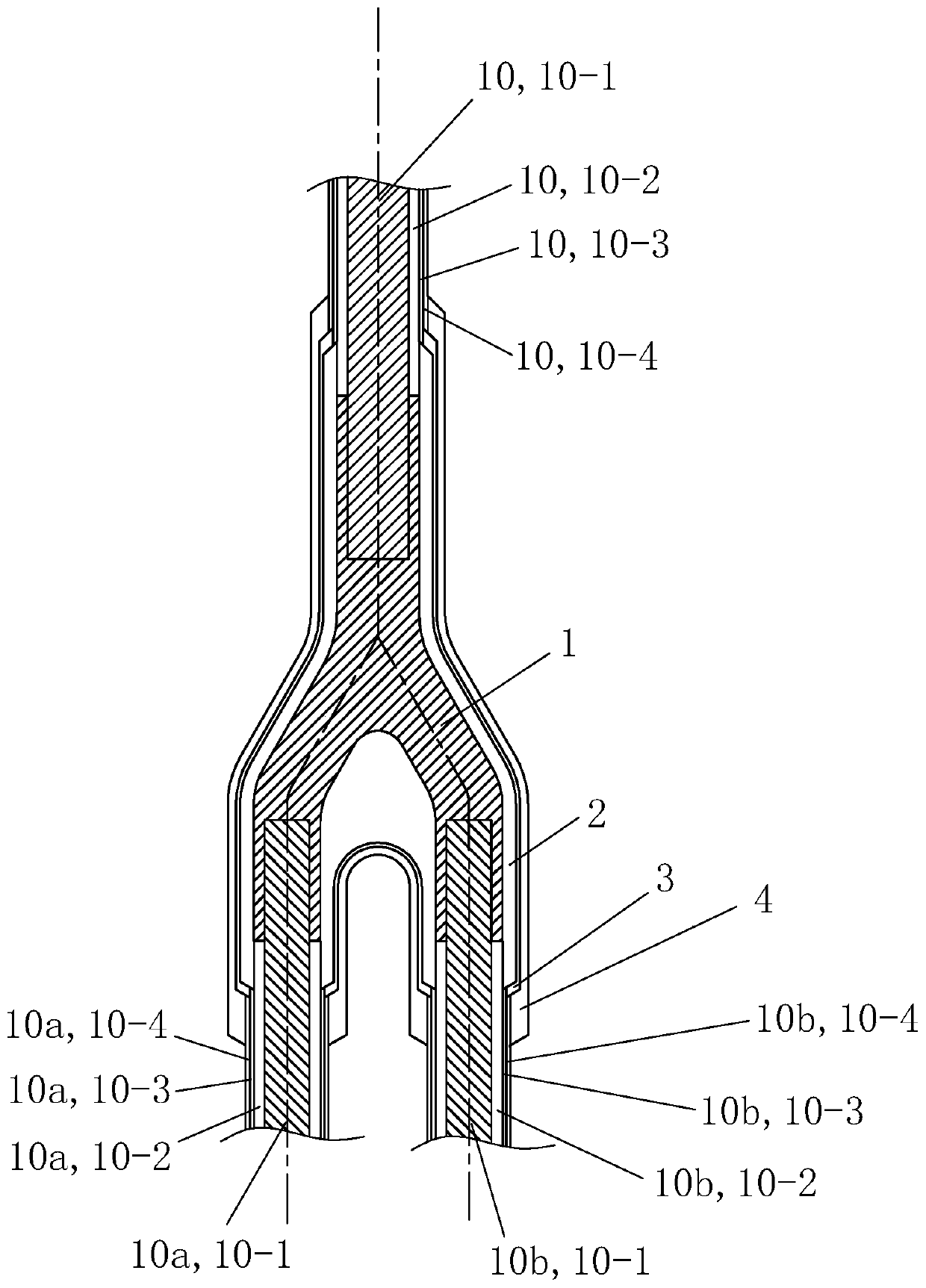

[0048] See Figure 1 to Figure 3 , The pre-branch cable of the present invention includes a trunk line cable 10, branch cables and connecting joints. The connecting joint includes a conductor connecting fitting 1 , a fitting insulating layer 2 , a fitting shielding layer 3 and a fitting sheathing layer 4 . There are two branch cables, and the two branch cables are respectively called the first branch cable 10a and the second branch cable 10b. The first branch cable 10a and the second branch cable 10b are fixedly connected and electrically connected to the trunk line cable 10 through the connection joint.

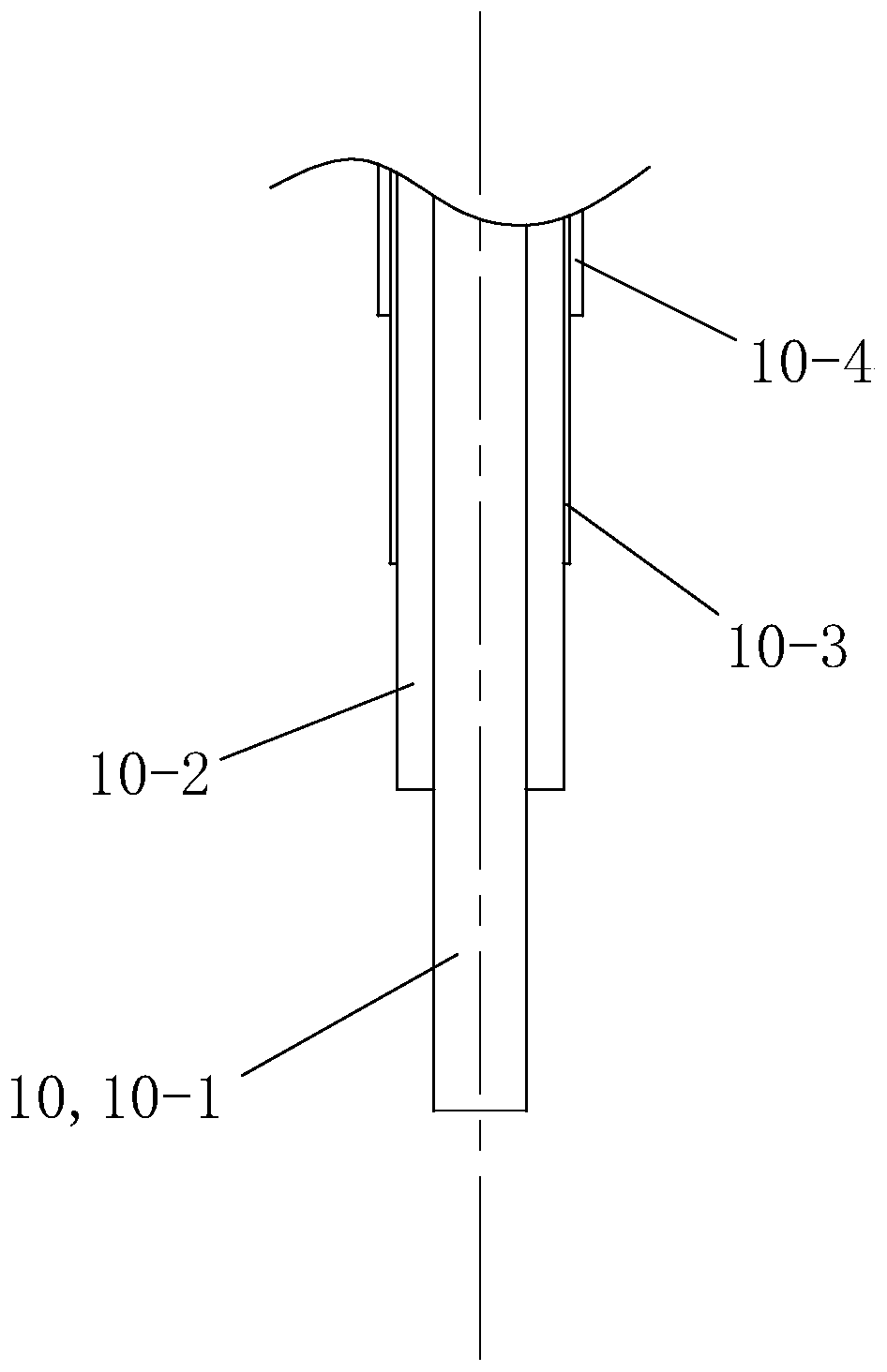

[0049] The trunk line cable 10, the first branch cable 10a and the second branch cable 10b have the same structure, and all include a cable conductor 10-1, a cable insulation layer 10-2, a cable shielding layer 10-3 and a cable sheathing layer 10-4. The cross-sectional area of the cable conductor 10 - 1 of the first branch cable 10 a and the second branch cable 10 b is s...

Embodiment 2

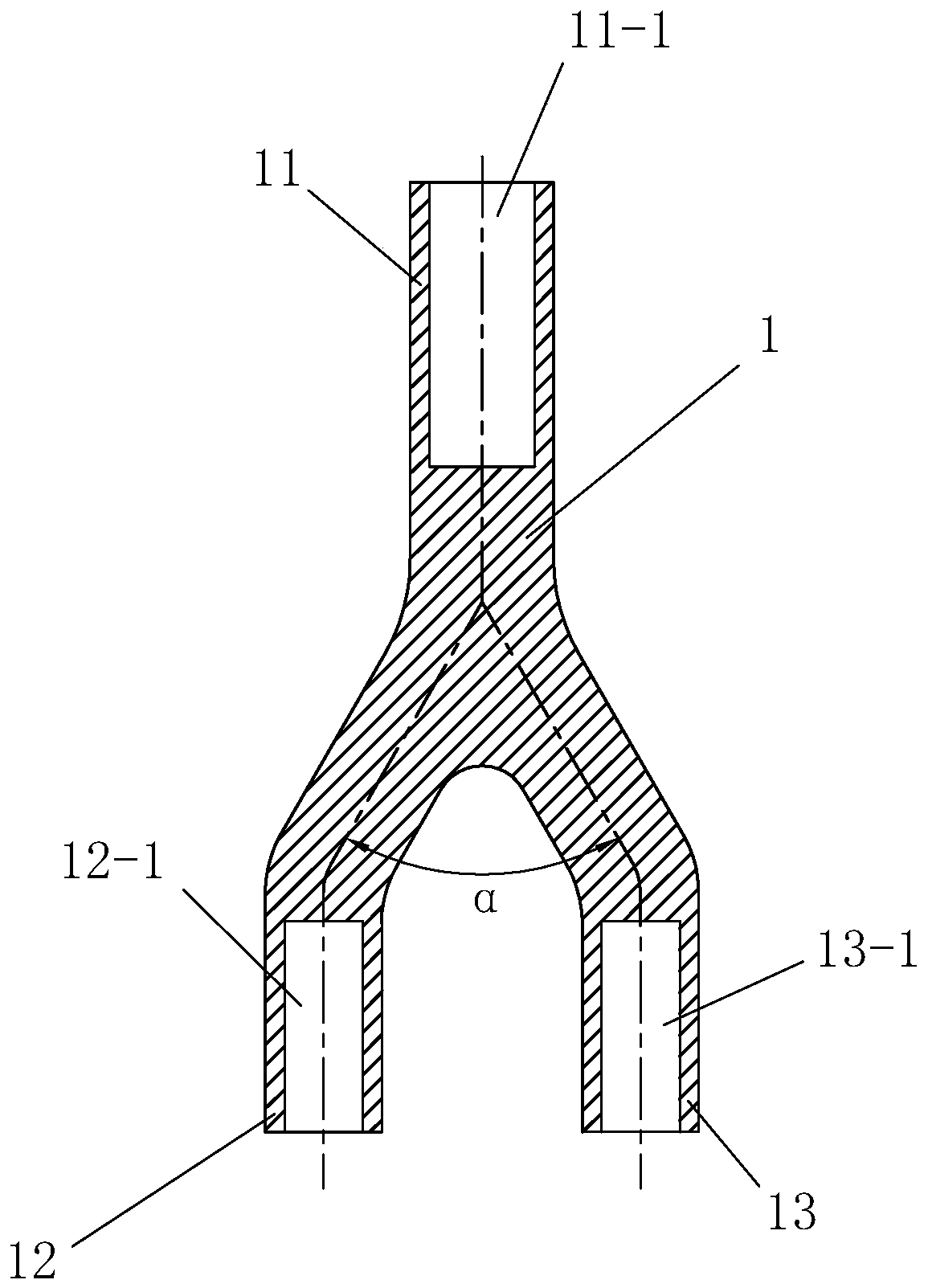

[0065] See Figure 4 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the main line connection part 11, the first branch connection part 12 and the second branch connection part 13 of the conductor connection fittings are arranged in a T shape in the same plane, The first branch connection part 12 and the second branch connection part 13 are arranged in a straight line, that is, the angle α at the intersection of one end of the first branch connection part 12 and the second branch connection part 13 is 180 degrees, and the main line connection part 11 is vertical It is arranged on the middle part of the first branch connection part 12 and the second branch connection part 13 .

Embodiment 3

[0067] See Figure 5 to Figure 9 , the rest of this embodiment is the same as Embodiment 1, the difference is that it also includes a third branch cable, the structure of the third branch cable is the same as that of the first branch cable 10a and the second branch cable 10b, and the third branch cable The sectional area of the cable conductor 10-1 of the cable is equal to the sectional area of the cable conductor 10-1 of the first branch cable 10a.

[0068]The conductor connecting hardware further includes a third branch connecting portion 14 . One end of the first branch connecting portion 12 , the second branch connecting portion 13 and the third branch connecting portion 14 are connected, and the other ends are arranged parallel to each other. The first branch connecting portion 12 , the second branch connecting portion 13 and the third branch connecting portion 14 are distributed in an equilateral triangle. The main line connecting portion 11 is disposed at the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com