Transformer insulation lifting parts

A transformer and hoisting technology, which is applied in the direction of load hanging components, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of reduced size of insulating hoisting parts, unreliable combination, unstable electrical performance, etc., and achieve reduction Effect of partial discharge, improvement of electric field distribution, and improvement of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

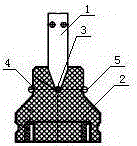

[0011] like figure 1 As shown, the insulating hoisting part is formed by connecting a metal connecting plate 1 and an insulating hoisting column 2 . The insulating hoisting column is cast with epoxy resin material, which is the same material as the transformer insulation protection body. The conical end of the metal connection plate is poured into the insulating hoisting column, the conical top is welded with a steel ball 3, and the other end is used for fixed connection on the iron core yoke of the transformer. An annular guide groove 4 is provided on the peripheral wall of the insulating lifting column opposite to the steel ball, and a shield spring 5 is provided as a shielding part for tip shielding in the guide groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com