Rotor blade boss energy storage spot welding repair clamping device and clamping method

A technology of rotor blades and clamping devices, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of blade damage caused by tip discharge, achieve the effects of shortening the production cycle, good electrical conductivity, and avoiding tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

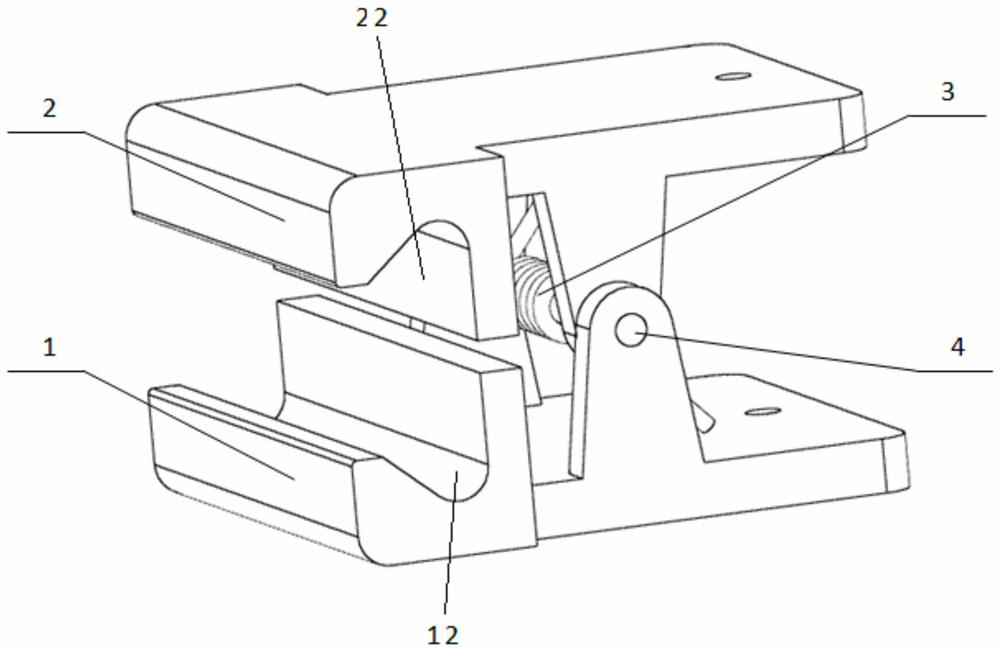

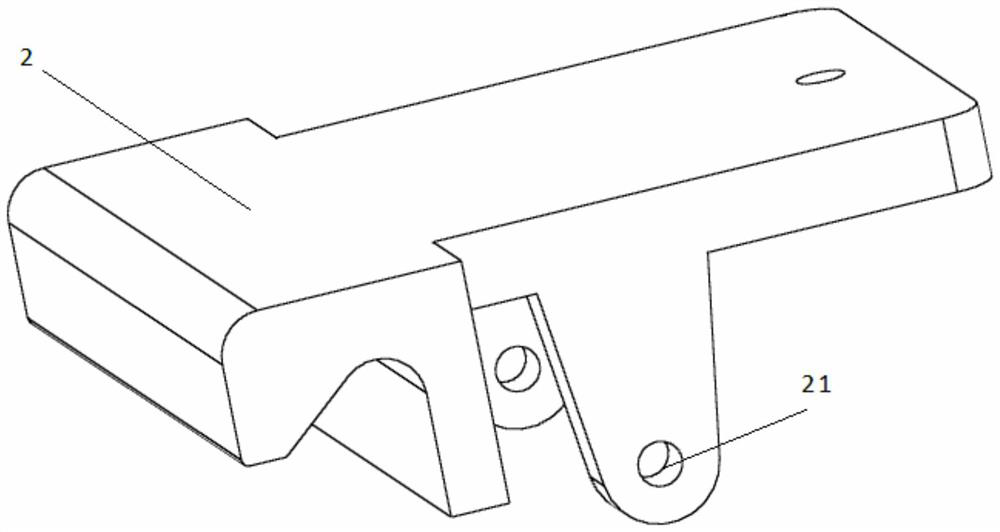

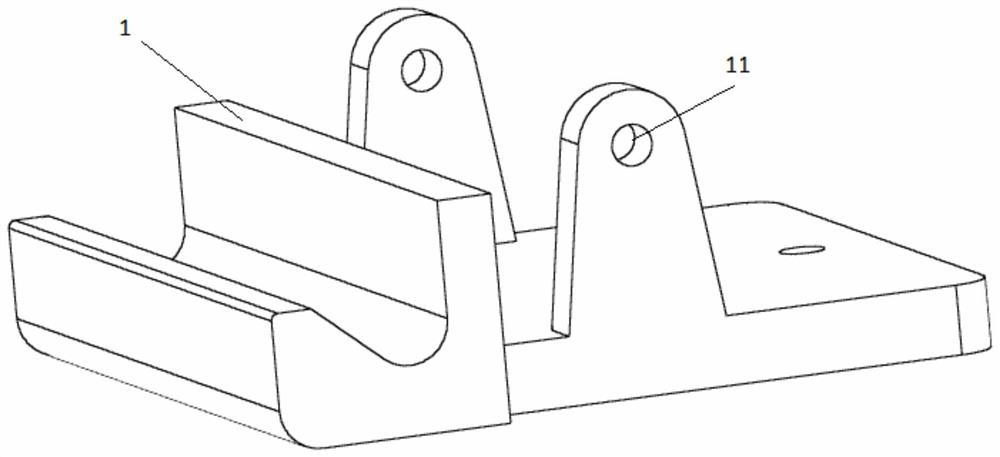

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown rotor blade boss energy storage spot welding repair clamping device includes an upper splint 2 and a lower splint 1, and the upper splint 2 and the lower splint 1 are installed through the upper splint installation hole 21 and the lower splint installation hole 11. The inner mounting pin 4 is rotatably connected, and the outer mounting pin 4 is provided with a torsion spring 3, and the upper splint 2 and the lower splint 1 are clamped by driving the torsion spring 3, and the upper splint 2 and the lower splint 1 are made of For copper.

[0016] The clamping method in actual use is as follows, including the following steps: a. First, open the upper clamping plate 2 and the lower clamping plate 1, and put the tenon of the rotor blade to be repaired between the upper clamping plate 2 and the lower cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com