Circular-arc microstrip curve plane slow wave device

A circular arc and microstrip technology, applied in the field of semicircular arc microstrip curved plane slow wave devices, can solve the problems of low coupling impedance and output power, difficulty in meeting strength requirements, poor heat dissipation, etc., and achieve improved coupling impedance and Effects of output power, improvement of strength and heat dissipation, and avoidance of reflection phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

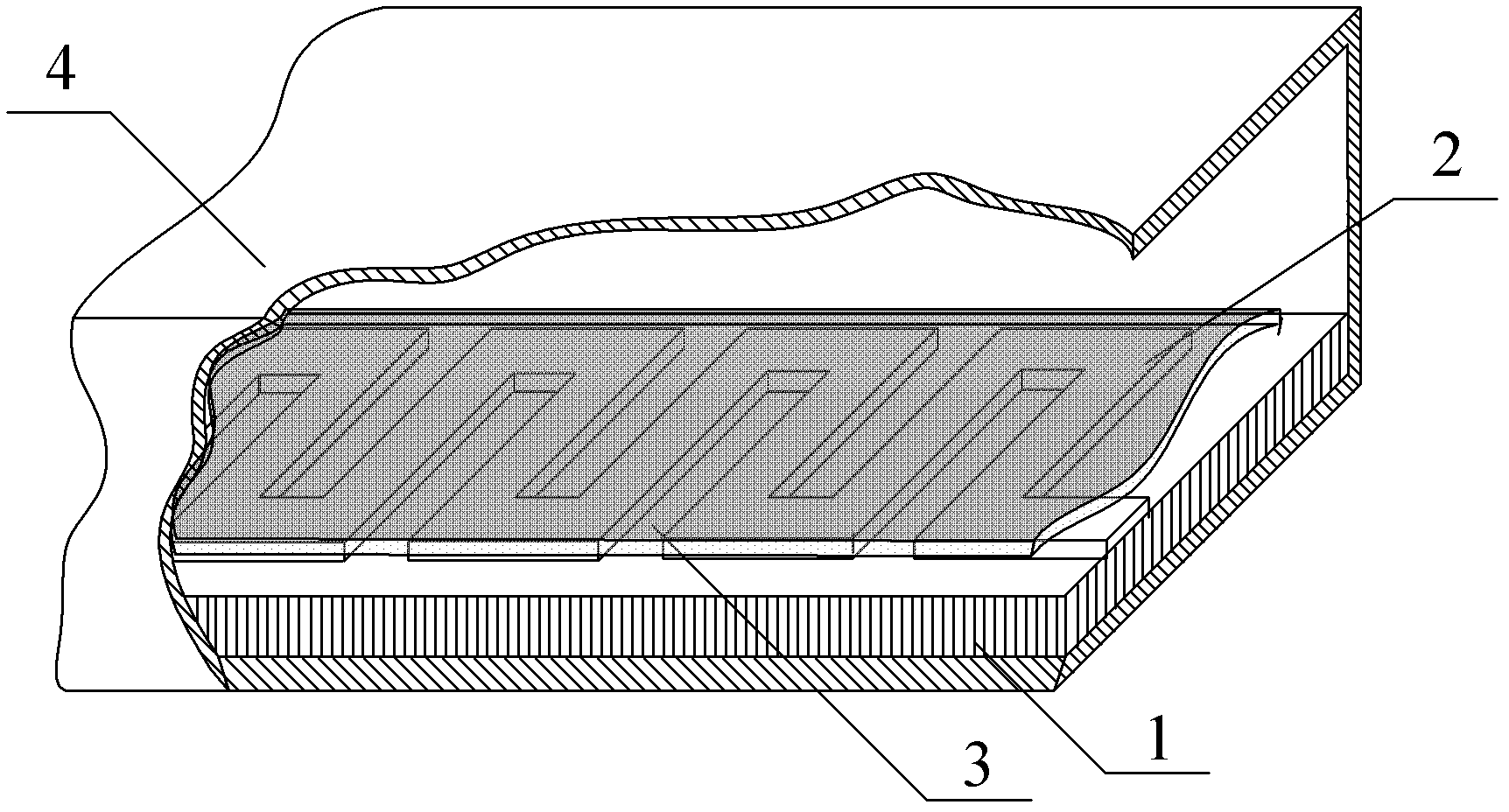

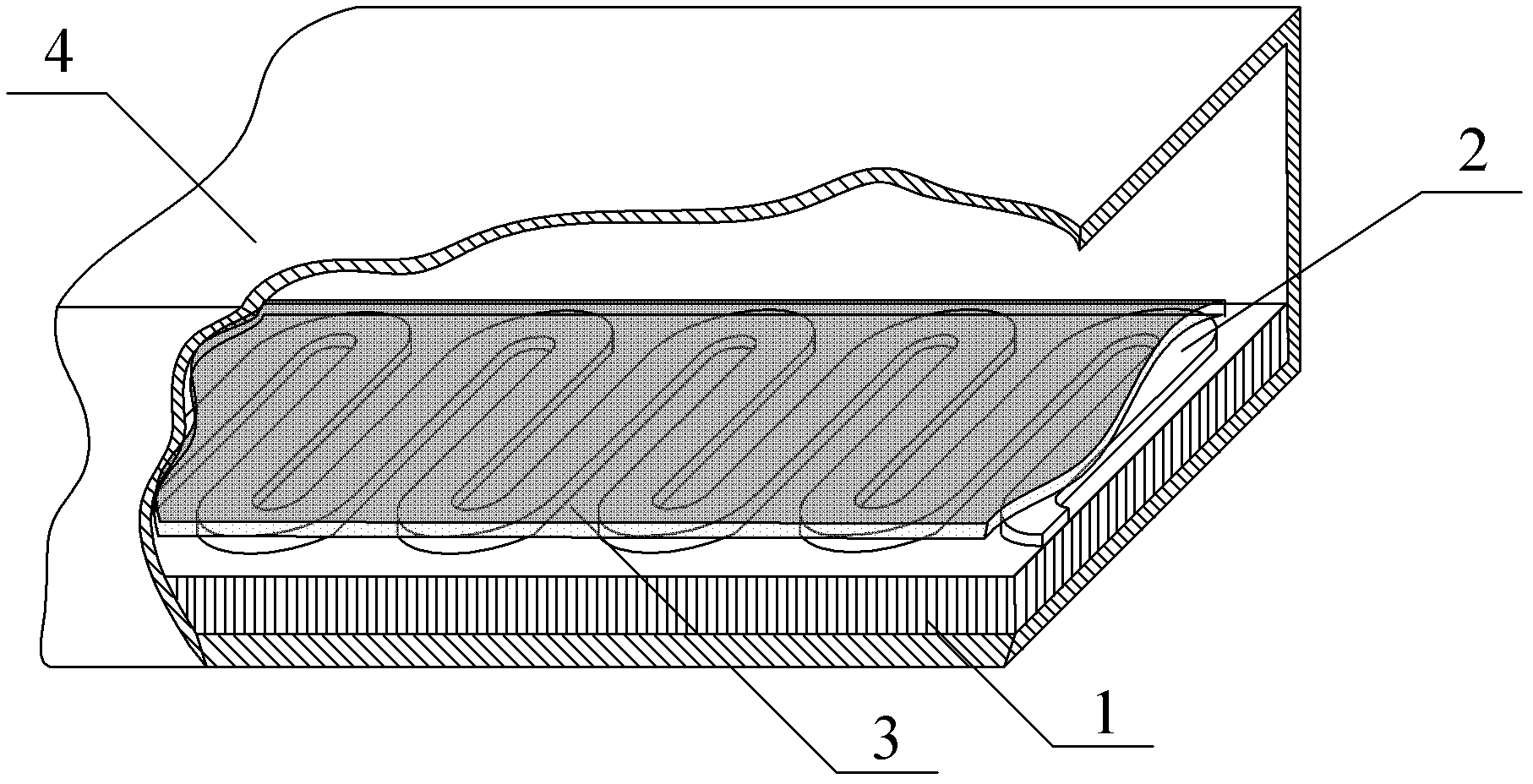

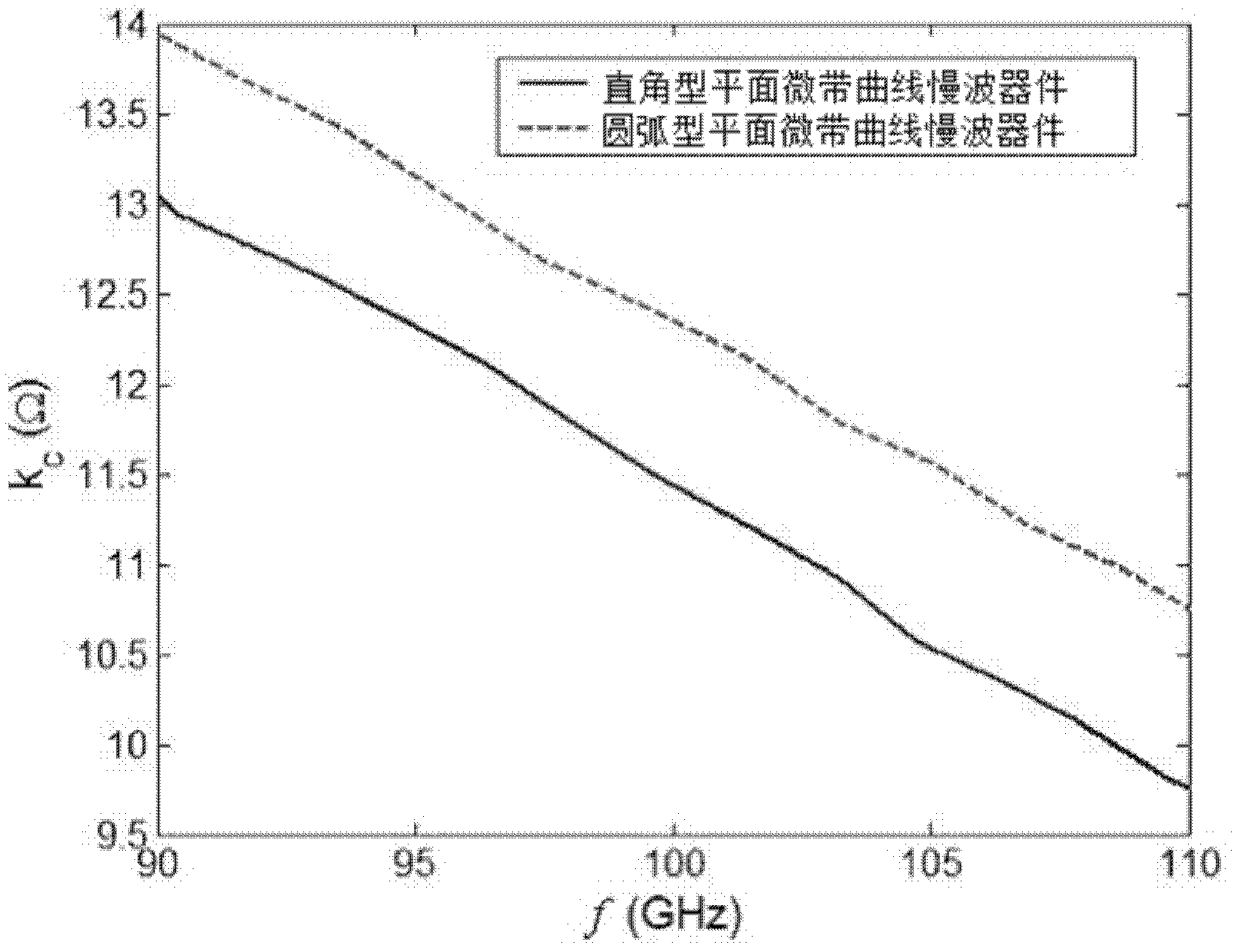

[0017] In this embodiment, an arc-shaped microstrip curved planar slow-wave device working in the 90-110 GHz band is taken as an example, in which: the substrate 1 (length×width×thickness) is 14.72×0.5×0.05mm, and the material is Purity 99wt%, relative permittivity ε r =4, boron nitride with loss tangent tanδ=0.00025; the line body (length×width×thickness) of the microstrip line 2 is 81.48×0.04×0.015mm, the material is metal Cu, and the microstrip curve has a total of 92 periods. The microstrip curve is 14.72mm long along the electron beam direction (that is, each cycle is 0.16mm long along the electron beam direction), the interval between two adjacent parallel microstrips is 0.04mm, and the inner radius of the semicircular microstrip curve at the connection part Both are R0.02mm; the metal shell 4 (length×width×height) is 14.72×0.6×0.4mm; when used together, the front and rear ends are respectively connected to the electron gun and collector of the traveling wave tube. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com