Coaxial cable with compound inner conductor for use in shallow sea bed and manufacturing method thereof

A technology of coaxial cables and inner conductors, which is applied in submarine cables, cable/conductor manufacturing, coaxial cables/analog cables, etc. It can solve the problems of poor adaptability of communication cables, large cable resistance to pulling force, and signal transmission influence. , to achieve excellent moisture-proof penetration performance, smooth outer surface and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

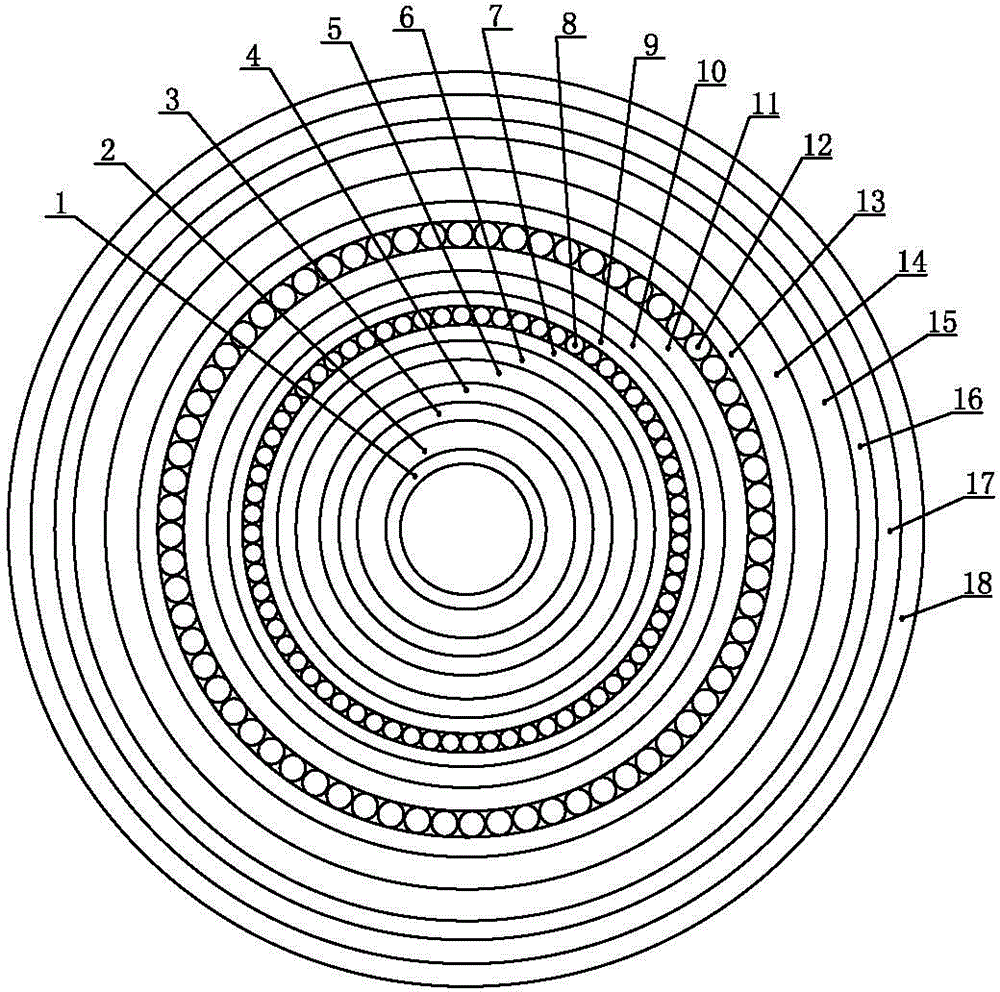

[0019] The present invention has a coaxial cable with a composite inner conductor for shallow sea and seabed, which is manufactured in the following steps: (1) Eleven soft copper round wires with a diameter of 0.6mm are concentrically twisted around the outer circumference of a solid annealed copper conductor with a diameter of 1.5mm to form a composite inner Conductor 1, the stranded pitch diameter ratio of the annealed copper round wire is 18 to 25 times; a high-voltage polyethylene insulating layer 2 with a nominal thickness of 3.5mm is extruded on the composite inner conductor 1, and the high-voltage polyethylene insulating layer is 2 The minimum thickness is not less than 90% of the nominal thickness, the maximum thickness is not greater than 110% of the nominal thickness, and the diameter deviation measured by any vertical section does not exceed 10%. (2) Nine soft flat copper wires with a width×thickness of 3.28mm×0.5mm are used to evenly braid the outer conductor 3 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com