A kind of preparation method of chitosan composite acetalized polyvinyl alcohol medical dressing

A technology of polyvinyl alcohol medicine and polyvinyl alcohol, which is applied in the field of preparation of chitosan composite acetalized polyvinyl alcohol medical dressings, which can solve the problems of insufficient mechanical strength, unsatisfactory tensile strength, and poor resistance to wound adhesion. , to achieve the effect of promoting wound healing, high mechanical tensile strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

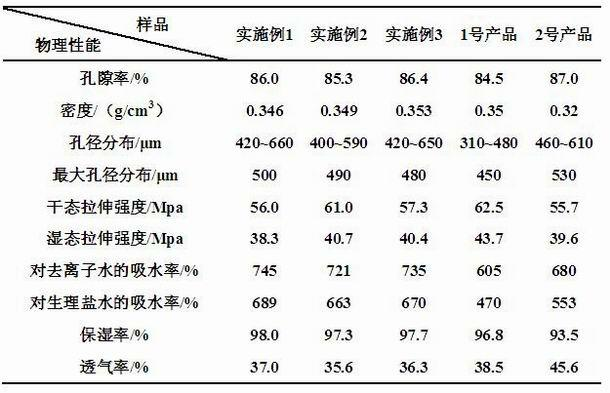

Embodiment 1

[0025] (1) Preparation of polyvinyl alcohol / chitosan blend: 0.05g chitosan was dissolved in 5mL 3% (wt.) acetic acid aqueous solution to obtain 1.0% (wt.) chitosan solution; deionized water was added to Heat to boiling at 90~100°C, mix 0.04g polyvinyl alcohol-AH26 with 0.01g polyvinyl alcohol-1799 to obtain 0.05g polyvinyl alcohol mixture, dissolve in 5mL boiling deionized water, cool to obtain 1.0% (wt. ) polyvinyl alcohol solution; mix 5mL chitosan solution and 5mL polyvinyl alcohol solution and stir thoroughly to obtain 10mL chitosan / polyvinyl alcohol blend;

[0026] (2) Preparation of acetalized polyvinyl alcohol: Mix 16g of polyvinyl alcohol-AH26 with 4g of polyvinyl alcohol-1799 to obtain 20g of polyvinyl alcohol mixture, heat deionized water to boiling at 90~100°C, and dissolve 20g of polyvinyl alcohol Dissolve the alcohol mixture in 200mL boiling deionized water, cool down to 55°C, add 0.20g sodium lauryl sulfate, 20mL 35% (wt.) formaldehyde solution, 2.0g sodium bicar...

Embodiment 2

[0031] (1) Preparation of polyvinyl alcohol / chitosan blend: 0.075g chitosan was dissolved in 5mL 1% (wt.) acetic acid aqueous solution to obtain 1.5% (wt.) chitosan solution; deionized water was added to Heat to boiling at 90~100°C, mix 0.09g polyvinyl alcohol-AH26 with 0.0225g polyvinyl alcohol-1799 to obtain 0.1125g polyvinyl alcohol mixture, dissolve in 7.5mL boiling deionized water, cool to obtain 1.5% (wt .) Polyvinyl alcohol solution; mix 5mL chitosan solution and 7.5mL polyvinyl alcohol solution and stir thoroughly to obtain 12.5mL chitosan / polyvinyl alcohol blend;

[0032](2) Preparation of acetalized polyvinyl alcohol: Mix 16g of polyvinyl alcohol-AH26 with 4g of polyvinyl alcohol-1799 to obtain 20g of polyvinyl alcohol mixture, heat deionized water to boiling at 90~100°C, and dissolve 20g of polyvinyl alcohol Dissolve the alcohol mixture in 120mL boiling deionized water, cool down to 45°C, add 0.10g sodium lauryl sulfate, 25mL 40% (wt.) formaldehyde solution, 3.0g so...

Embodiment 3

[0035] (1) Preparation of polyvinyl alcohol / chitosan blend: 0.025g chitosan was dissolved in 5mL 2% (wt.) acetic acid aqueous solution to obtain 0.5% (wt.) chitosan solution; deionized water was added to Heat to boiling at 90~100°C, mix 0.24g polyvinyl alcohol-AH26 with 0.06g polyvinyl alcohol-1799 to obtain 0.3g polyvinyl alcohol mixture, dissolve in 60mL boiling deionized water, cool to obtain 0.5% (wt. ) polyvinyl alcohol solution; mix 5mL chitosan solution and 6mL polyvinyl alcohol solution and stir thoroughly to obtain 11mL chitosan / polyvinyl alcohol blend;

[0036] (2) Preparation of acetalized polyvinyl alcohol: Mix 16g of polyvinyl alcohol-AH26 with 4g of polyvinyl alcohol-1799 to obtain 20g of polyvinyl alcohol mixture, heat deionized water to boiling at 90~100°C, and dissolve 20g of polyvinyl alcohol Dissolve the alcohol mixture in 150mL boiling deionized water, cool down to 30°C, add 0.05g sodium lauryl sulfate, 24mL 38% (wt.) formaldehyde solution, 1.0g sodium bica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com