Manufacturing method of multi-wire combined welding cable

A technology for welding cables and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, power cables, cables, etc., which can solve the problems of low temperature resistance, poor safety performance, and easy confusion of signals, etc., and achieve strong mechanical tensile strength and simple structure Reasonable and superior product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

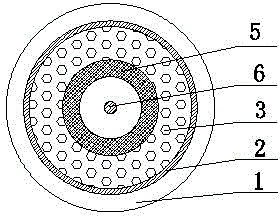

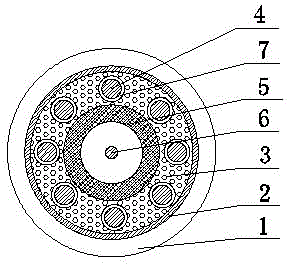

[0019] The multi-wire combined welding cable is composed of a cable core and an outer sheath 1 composed of a current conductor 3, a plurality of signal control cables 4, an inert gas tube 5, and a signal control carrier line 6. The current conductor is composed of a plurality of soft It is made of twisted oxygen-free copper wires, the inert gas tube is made of flexible elastomer composite polyvinyl chloride insulating material, and the signal control carrier line is made of twisted and fine-tuned tinned soft oxygen-free copper wires; the cable core The signal control carrier line in the cable is set in the inert gas tube, the current conductor in the cable core is evenly set around the outer circumference of the inert gas tube, the cable core is wrapped with non-woven cloth tape, and the cloth tape is extruded with flexible elastomer composite PVC insulation Outer sheath. The outer periphery of the inert gas pipe is evenly provided with signal control cables, and the signal co...

Embodiment 2

[0021] A method for manufacturing a multi-wire combined welding cable, comprising the following steps:

[0022] 1) The signal control carrier line 6 is made of tinned oxygen-free copper wires twisted into bundles.

[0023] 2) Use an extruder to extrude a polyvinyl chloride insulating material gas tube around the signal control carrier line prepared in step 1) to make an inert gas tube 5 with a built-in signal control carrier line 6 .

[0024] 3) A plurality of tinned soft oxygen-free copper wires are twisted into bundles to form the current conductor 3, preferably toughened fine tinned soft oxygen-free copper wires with a diameter of less than 3.0 mm.

[0025] 4) Evenly arrange the current conductor prepared in step 3) around the inert gas tube 5 prepared in step 2), and then wrap the non-woven fabric tape 2 around it. It is also possible to evenly arrange the current conductors around the inert gas pipe, and at the same time arrange the signal control cables evenly around th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com