Cable reel cable dividing machine

A cable reel and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of affecting the service life of the cable, the cable is easy to deform, and the tensile strength is not enough, so as to increase the mechanical tensile strength, improve the restoring force, The effect of prolonging the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

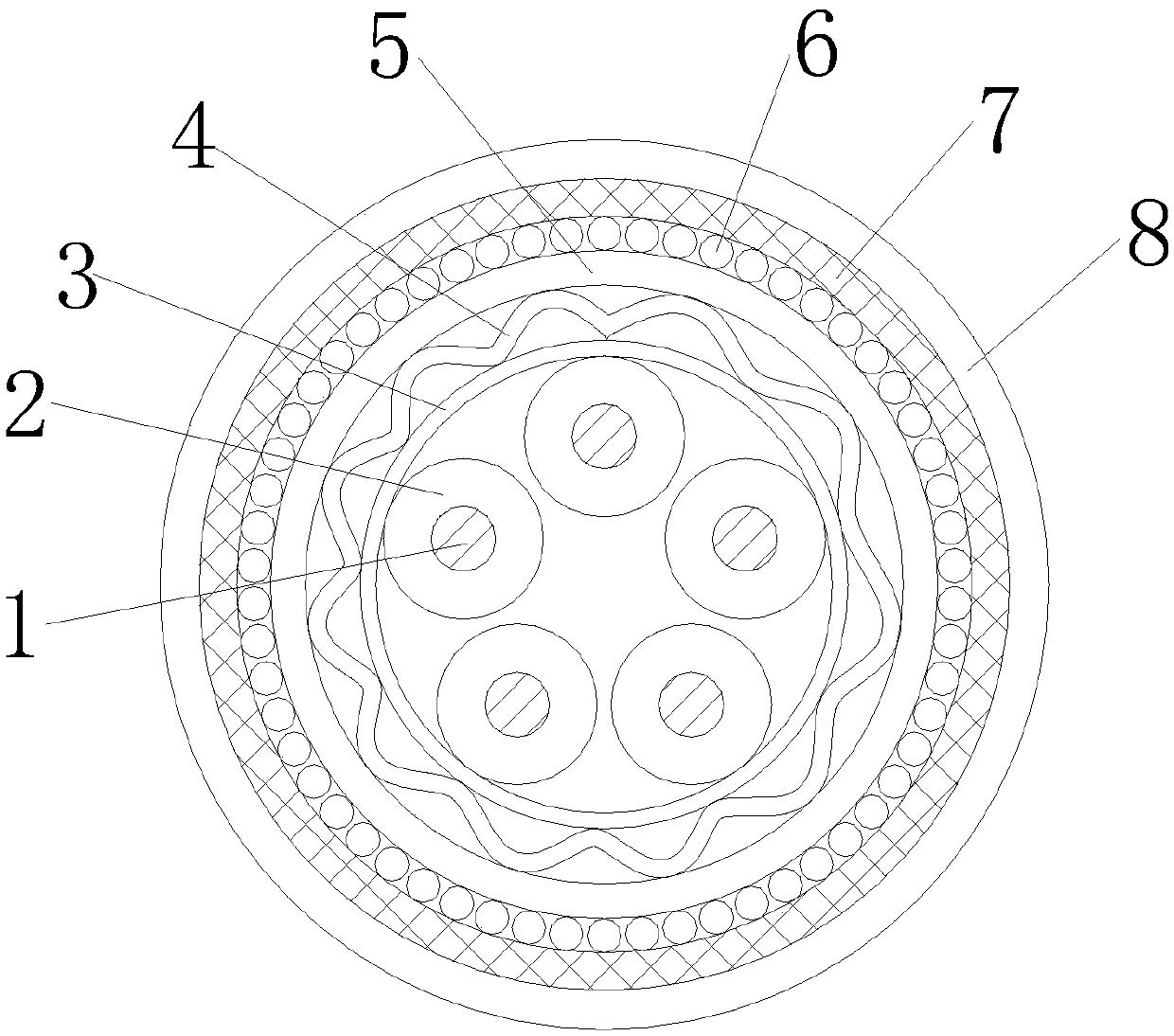

[0014] See figure 1 , figure 1 It is a schematic diagram of the structure of the present invention.

[0015] A cable reel cable separating machine includes a cable core 1 composed of a plurality of copper wires and an outer insulating sheath 8. The outer surface of each cable core 1 is provided with an inner insulating sleeve 2, and the inner insulating sleeve A cable wrapping tape 3 is arranged on the outside of the cable wrapping tape 3, and a return spring plate 4, a polyvinyl chloride sleeve 5, a copper wire armor layer 6 and a spring woven net 7 are sequentially arranged between the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com