Production method of nylon 66/ polycarbonate/ silicon rubber thermostability engineering plastic

A technology of polycarbonate and engineering plastics, which is applied in the field of high-temperature-resistant engineering plastics manufacturing, and can solve the problems of poor heat resistance of materials, low temperature resistance of ordinary rubber or elastomer, compatibility of polycarbonate and composite matrix And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-5

[0033] Both nylon 6 and polycarbonate were dried under vacuum at 90°C for 14 hours, and the montmorillonite was dried in an air-circulating oven at 80°C for 4 hours before mixing. Nylon 6 / polycarbonate / silicone rubber compound is dynamically vulcanized in a co-rotating twin-screw extruder. The barrel temperature is between 270-285°C, and the rotation speed is between 60-90rpm. Cool in a water bath after extrusion and start granulation. The formulation of the nylon 66 / polycarbonate / silicone rubber compound is shown in Table 1.

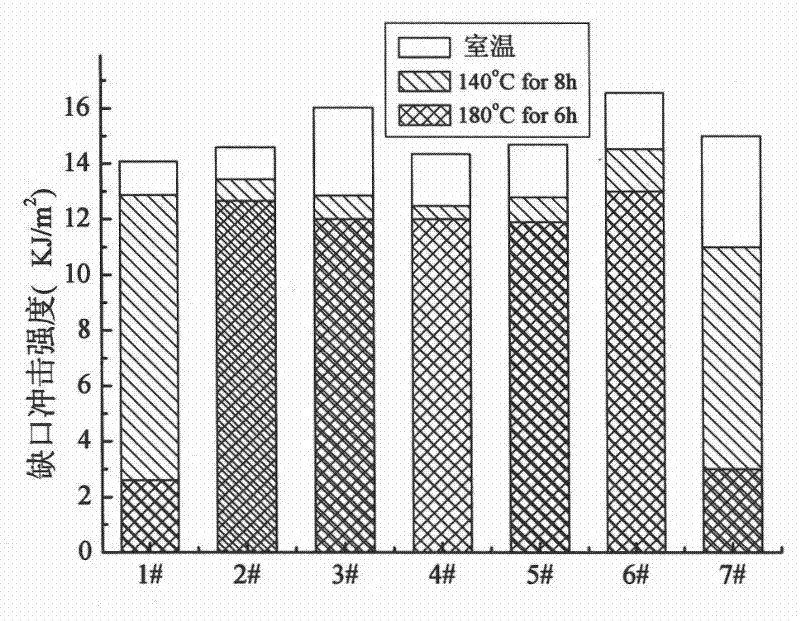

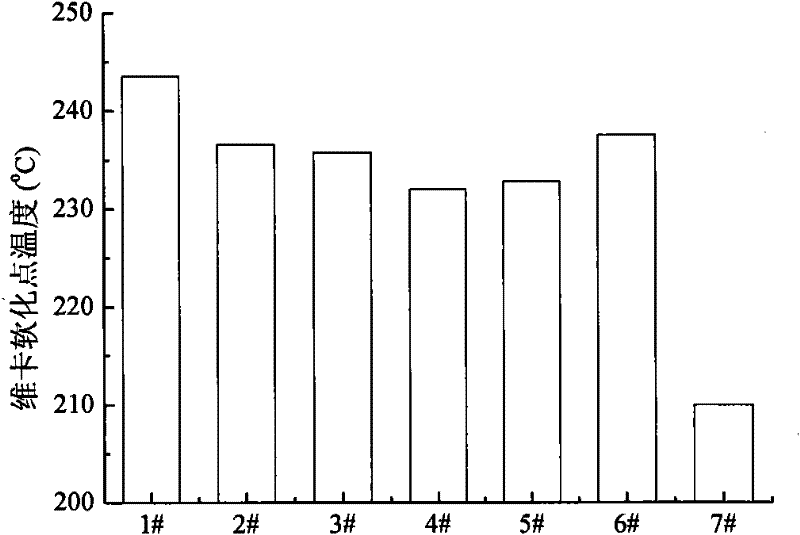

[0034] Subsequent injection molding was carried out in a plastic injection molding machine at an injection temperature of 275°C. Injection speed and pressure are 11.5cm 3 / s and 2300bar. Gained composite toughened nylon 66 engineering plastics carries out performance test, and the results are shown in Table 2, figure 2 and image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com