Patents

Literature

46results about How to "Effective against insects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

APG (alkyl polyglucoside) plant environmentally-friendly shampoo

InactiveCN102210644AReduce surface tensionStrong wetting powerCosmetic preparationsHair cosmeticsIrritationSkin irritant

The invention discloses an APG (alkyl polyglucoside) plant environmentally-friendly shampoo which comprises APG (alkyl polyglucoside), coconut oil 6501, water-soluble wool grease, cocamidopropylamine oxide, emulsified silicon oil softener, EDTA (ethyle, diamine tetraacetic acid), citric acid, sodium alginate, Germall, plant additive and water. The APG plant environmentally-friendly shampoo has the effects of effectively resisting hair dropping, blacking hair, shinning hair, nourishing hair, sterilizing, removing dandruff and relieving itching, has small skin irritation, and does not produce drug resistance after being used for long term.

Owner:董家华 +1

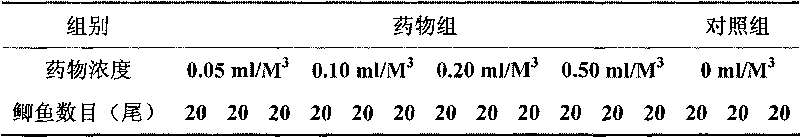

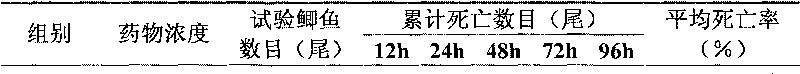

Compound pesticide for fishing and preparation method and application thereof

ActiveCN101690767ADefinite curative effectSignificant effectAntiparasitic agentsNitrile/isonitrile active ingredientsCypermethrinSide effect

The invention discloses a compound pesticide for fishing; the compound pesticide can be used for preventing aquatic livestock parasitic diseases caused by parasites such as trichodina, dactylogyrus, gyrodactylus, Chinese daphnia, lernaean, sporozoit and the like, belonging to the field of veterinary drugs. The ingredients of the compound pesticide for fishing are composed of radix sophorae flavescentis, betel palm, stone-like omphalia and cypermethrin; the preparation method of the compound pesticide is that: the radix sophorae flavescentis, betel palm and stone-like omphalia are weighted according to the proportion, refluxing and extraction are carried out, extracting solution is heated, evaporated and concentrated, and then cypermethrin, emulsifying agents, organic solvent and distilled water are added for preparation according to the proportion; the compound pesticide for fishing has the advantage of stable quality, convenient usage, low cost, having remarkable curative effect on the trichodina, dactylogyrus, gyrodactylus, Chinese daphnia, lernaean, sporozoit diseases of the aquatic livestock, rapid effect, thorough killing, small toxic and side effect and wide parasite expelling and killing spectra, and can effectively ensure health and safety of aquaculture animals.

Owner:BEIJING DABEINONG ANIMAL HEALTH TECH

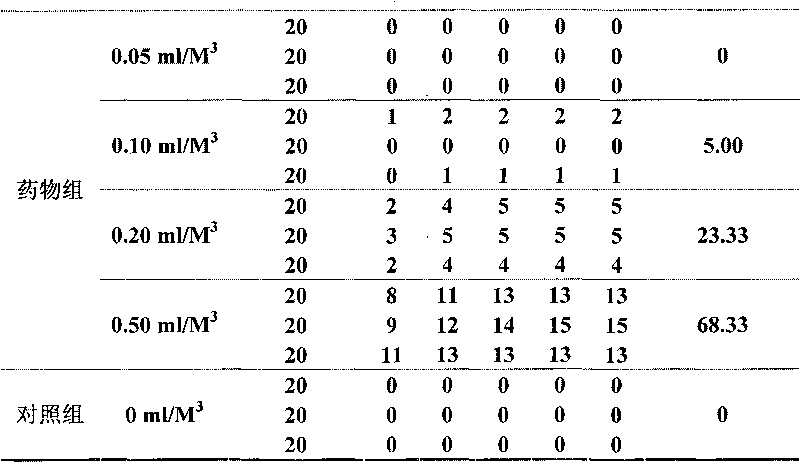

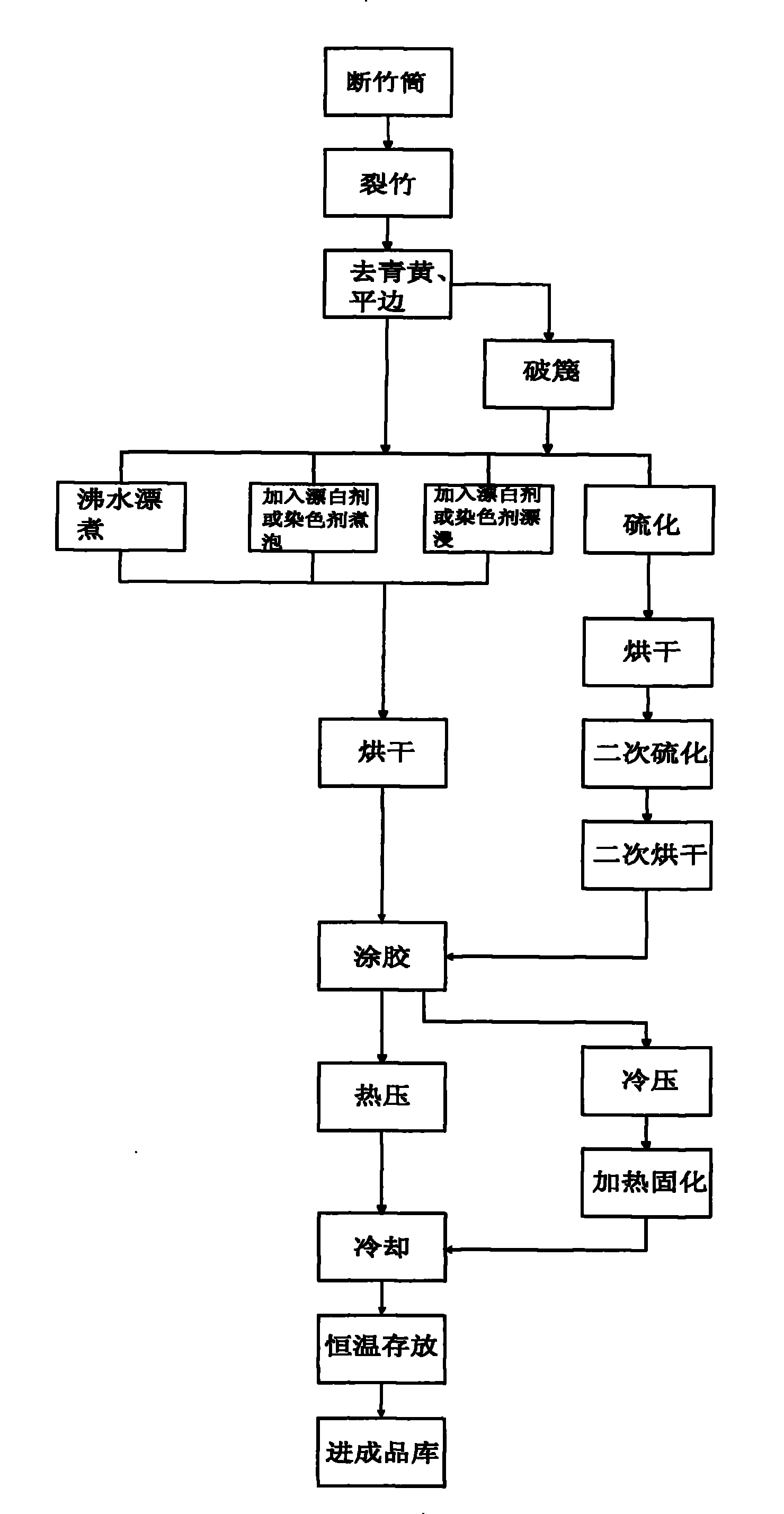

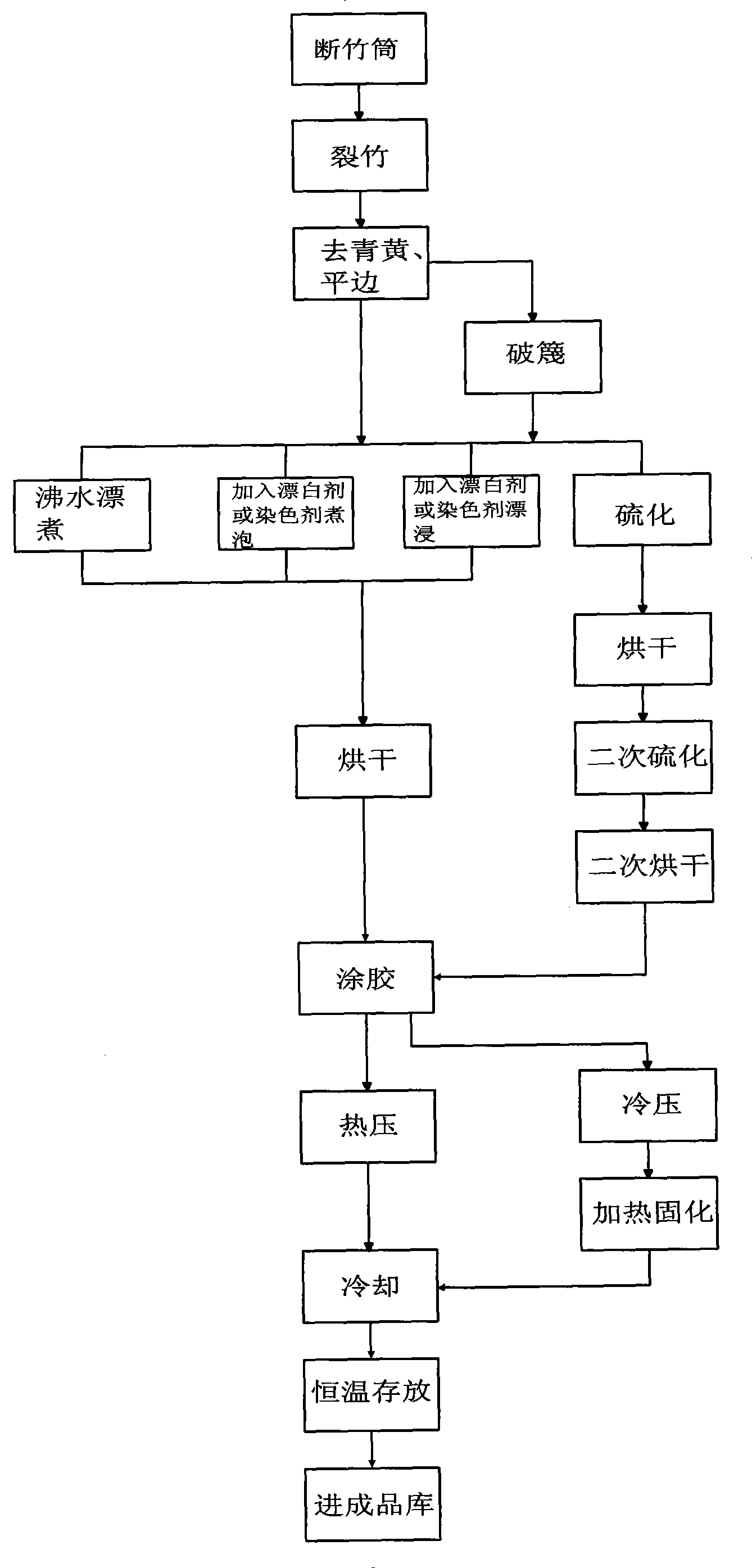

Production method bamboo strip side pressing bamboo board

InactiveCN101417457AJieba XiaoxianIncrease profitCane mechanical workingReed/straw treatmentElectricityResist

The invention relates to a manufacturing method of bamboo boards by side standing pressing of bamboo chips, including the following steps: bamboo chips or bamboo stripes initially processed according to required sizes are put into a kiering pool to be brewed with boiling water or are placed into a kiering pool with insect-resist agents, mold preventing agents, bleachers or coloring agents to be brewed with boiling water or placed into a dip bleaching pool with bleachers or coloring agents to be dip-bleached; the bamboo chips or bamboo stripes are directly placed into an autoclave for high temperature steam and sulfuration; a resin adhesive is uniformly coated on bottom surfaces and surfaces of the dried bamboo chips or bamboo stripes; the glued bamboo chips or bamboo stripes are sent into a hot-press to be hot-pressed until the glue is solidified; the chips or stripes are cooled to the normal temperature, then stored in a constant-temperature house for 30 days and then cut into finished products according to needed dimensions. The surfaces of the bamboo boards are natural textures formed by the lamination of sides of slices of bamboo chips and are beautiful without knots; the boards are larger in bearing capacity, little in gel content of finished products, more good for the environmental protection and hard to deform; and compared with the prior art, the method is high in efficacy, saves electricity, improves the utilization efficiency of original bamboos and saves cost.

Owner:赵斌

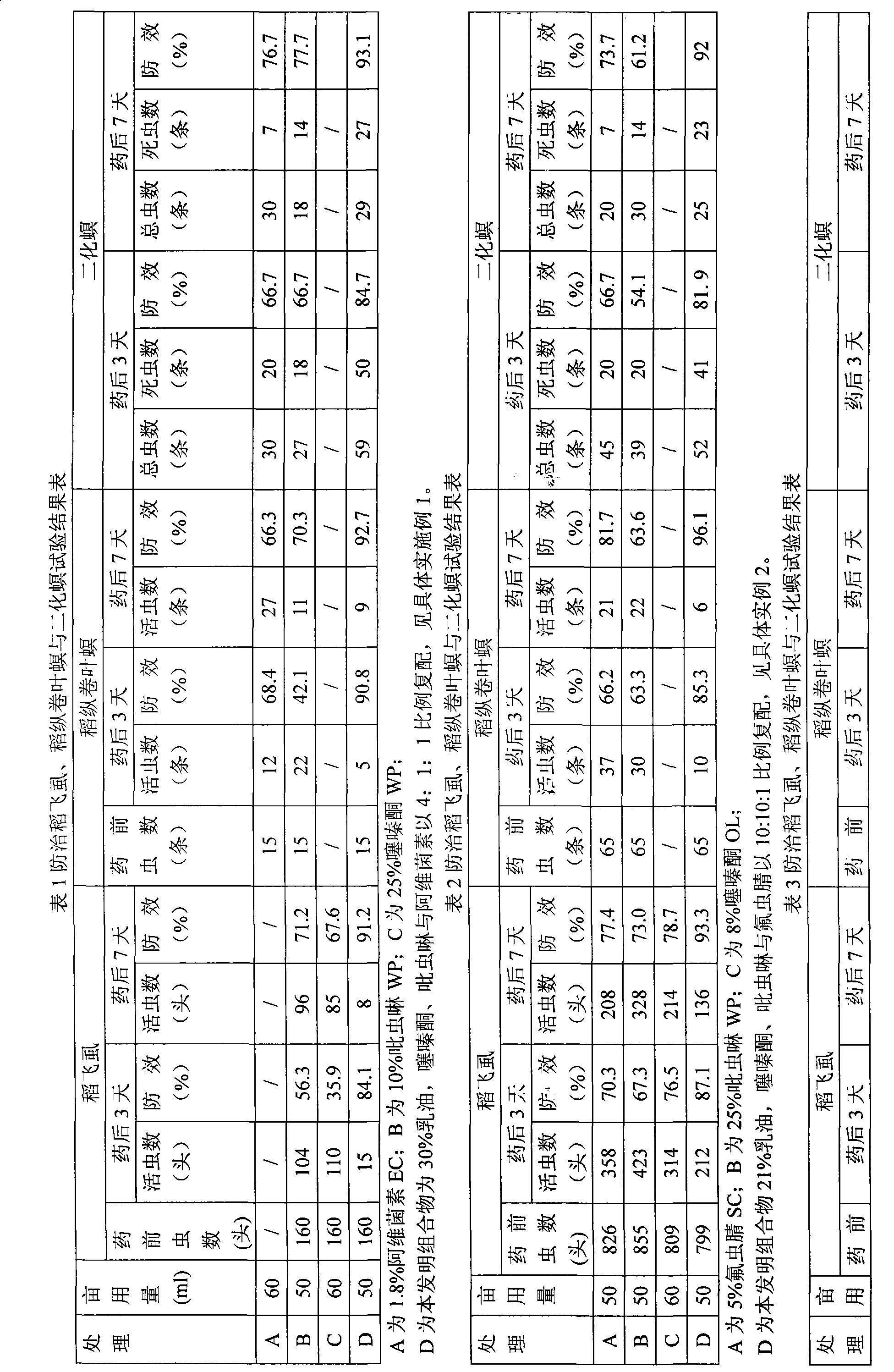

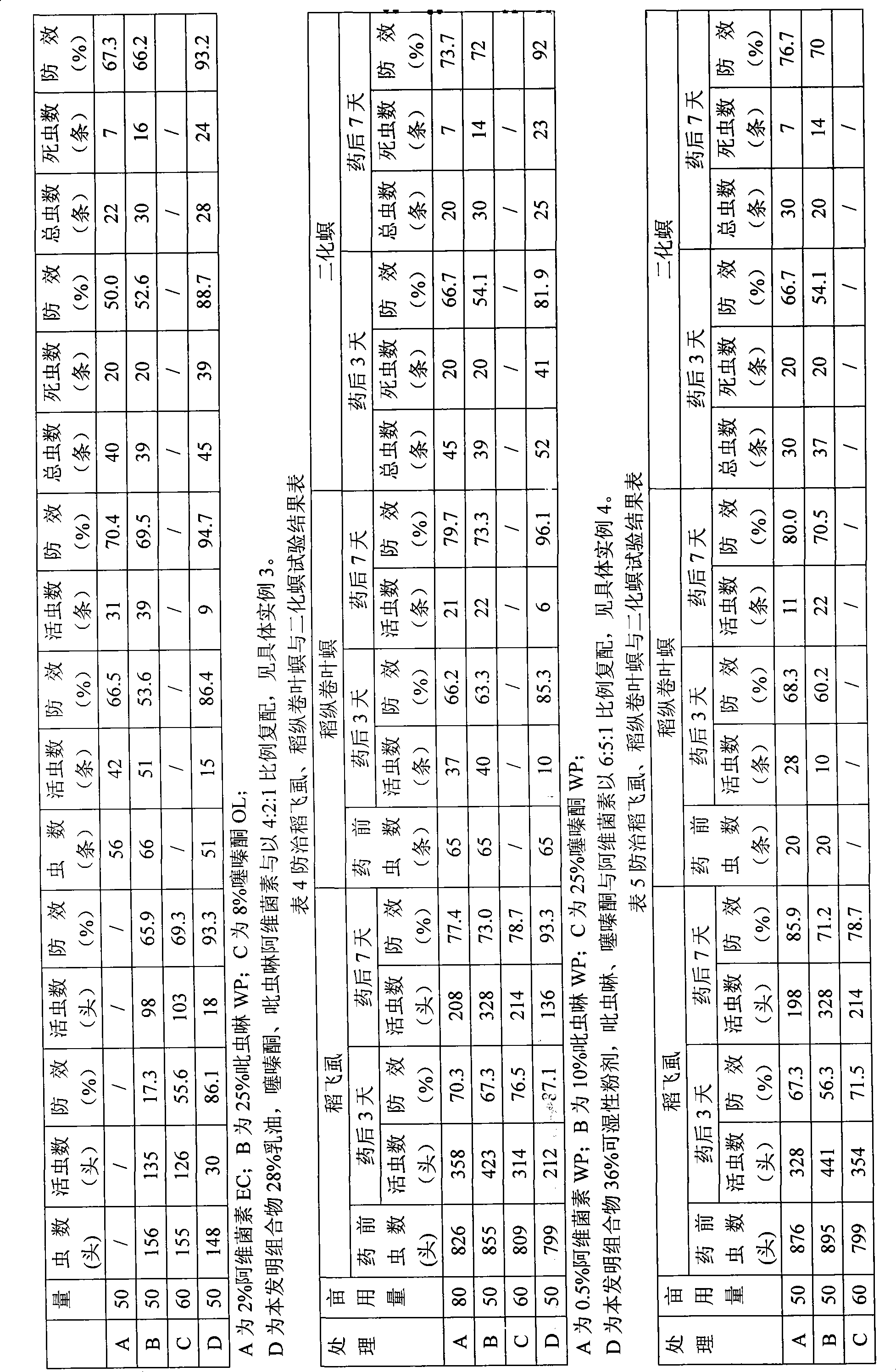

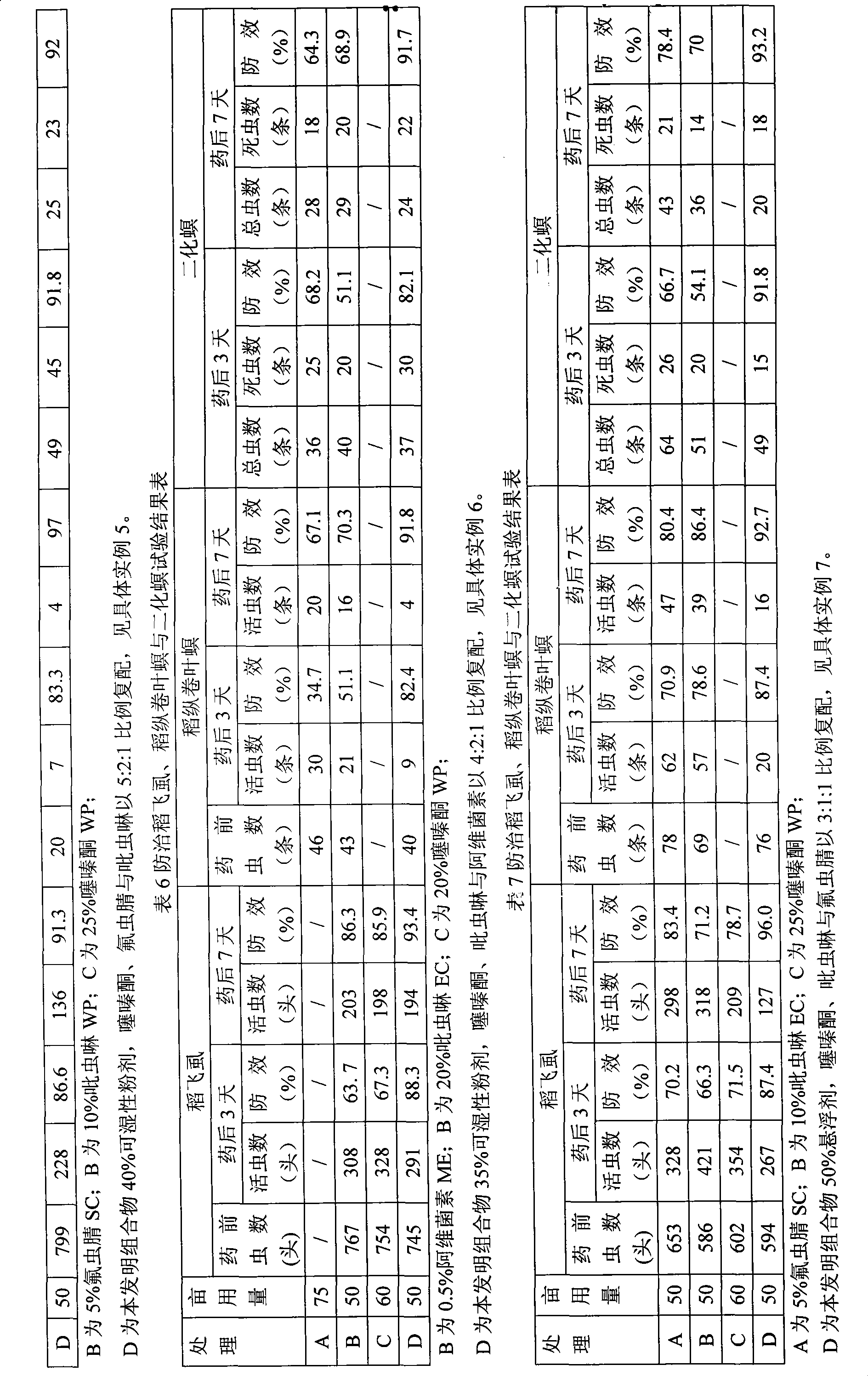

Compound formulation for paddy pest control

InactiveCN101444203AIncrease lethalityGood prevention effectBiocideArthropodicidesFipronilEcological environment

The invention provides an efficient and low-noxious compound formulation for paddy pest control, having the effective components of abamectin or fipronil, buprofezin, imidacloprid assisted with the emulsifier, the insecticide synergist combination. The ternary mixtures of pesticides of the invention can complement several different mechanisms of insecticide mixed together to complement each other, the first application, we can effectively combat a wide range of pests rice. At the same time be able to delay the rice pest resistance to produce a single Pharmacy to address the rice problem of pest resistance, a decrease of rice, the pesticide residues in aquatic products, protection of ecological environment.

Owner:湖南万家丰科技有限公司

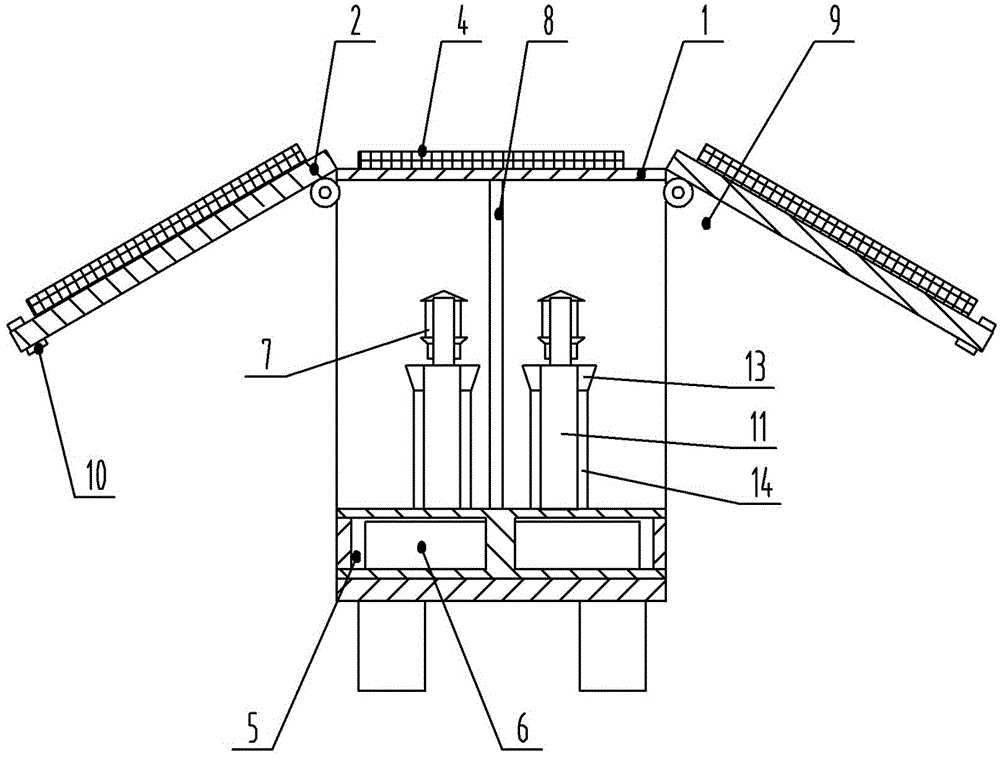

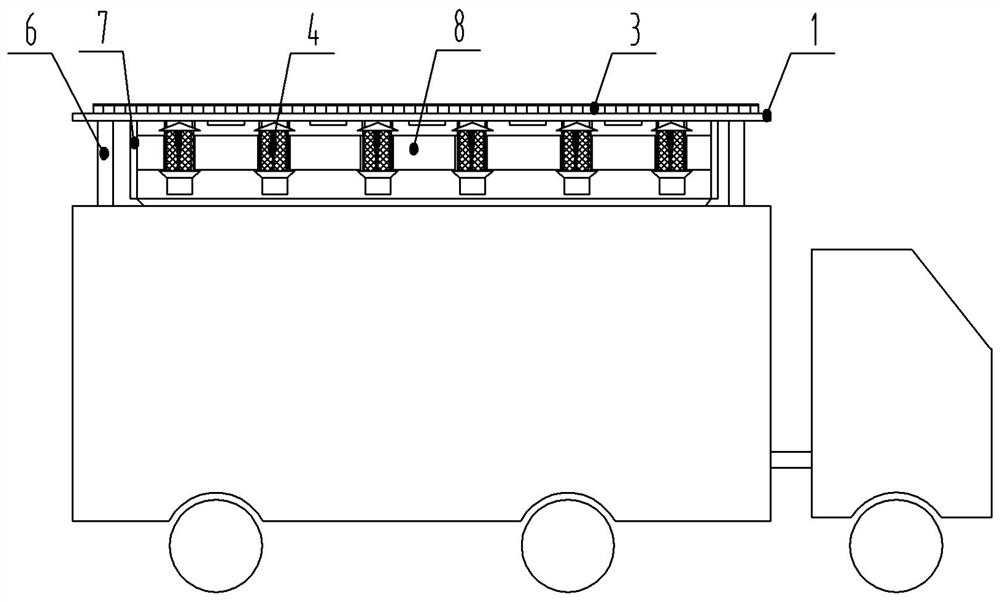

Solar photovoltaic harmful insect protection and control vehicle

InactiveCN104396916ATo achieve the purpose of harm controlEasy to useItem transportation vehiclesInsect catchers and killersAgricultural scienceAgricultural engineering

The invention belongs to the technical field of protection and control of harmful insects, and in particular relates to a solar photovoltaic harmful insect protection and control vehicle. The solar photovoltaic harmful insect protection and control vehicle includes a carriage including a top plate, two side plates and a rear baffle plate, wherein a solar photovoltaic module is embedded on the outer surface of the carriage, a storage battery bin is arranged at the bottom of the side of the carriage, a storage battery is put in the storage battery bin, at least a row of insecticidal lamps are longitudinally arranged in the carriage, an insect collecting groove and an insect collecting box are sequentially arranged under the insecticidal lamps. The solar photovoltaic harmful insect protection and control vehicle can move to and fro, can be self-powered, and is convenient to use and wide in application range; furthermore, the solar photovoltaic harmful insect protection and control vehicle is good in the insect trapping and killing effect, can trap and kill the harmful insects in large area, and thereby is very suitable for popularization.

Owner:田保卫

Special pesticide used for litchis

InactiveCN105851084AEffective against insectsEfficient killingBiocideDead animal preservationPumpkin seedAgrimonia eupatoria

The invention discloses a special pesticide used for litchis. The special pesticide is prepared through decocting raw materials in water, and the raw materials comprise, by weight, 10-20 parts of sophora flavescens, 12-15 parts of Common Carpesium Fruit, 10-14 parts of Cyrtomium fortunei, 8-15 parts of aloe, 8-12 parts of morning glory seeds, 6-12 parts of Chinese prickly ash, 6-10 parts of Fructus Toosendan, 5-8 parts of Cortex Meliae, 6-8 parts of betel nut, 3-8 parts of Gleditsia sinensis, 3-6 parts of Common Threewingnut Root, 2-4 parts of Agrimonia eupatoria, 2-5 parts of Quisqualis indica, 1-4 parts of pumpkin seeds and 1-3 parts of Gemma Agrimoninae. A decoction obtained after decocting all traditional Chinese medicinal components through a reasonable method is sprayed to form a natural medicine protection layer on the surfaces of fruits and effectively kill pests on the surfaces of the fruits; and medicines release smell, so breeding of the pests is effectively prevented.

Owner:LIUZHOU XINXIN FRUIT PLANTATION

Pesticide special for strawberries

InactiveCN105767054AEffective against insectsAvoid breedingBiocideDead animal preservationBiotechnologyFragaria

The invention discloses a pesticide special for strawberries.The pesticide is prepared by decocting, by weight, 10-20 parts of radix sophorae flavescentis, 12-15 parts of common carpesium fruits, 12-18 parts of Chinese torreya, 10-14 parts of Cyrtomium fortune, 8-12 parts of semen pharbitidis, 6-10 parts of szechwan Chinaberry fruits, 5-8 parts of azedarach, 6-8 parts of betel nuts, 4-6 parts of radix stemonae, 3-8 parts of Chinese honey locust, 2-4 parts of hairyvein agrimony, 2-5 parts of fruits of Rangoon creepers, 1-4 parts of pumpkin seeds, 1-3 parts of gemma agrimoninae and 1-2 parts of stone-like omphalia.The pesticide special for strawberries has the advantages that a decoction solution obtained by decocting the traditional Chinese medicine components by adopting a reasonable method for spraying, a natural medicine protective layer can be formed on the surface of a fruit, injurious insects on the surface of the fruit are effectively killed, and meanwhile the smell emitted by the medicines can effectively prevent breeding of injurious insects.

Owner:LIUZHOU XINXIN FRUIT PLANTATION

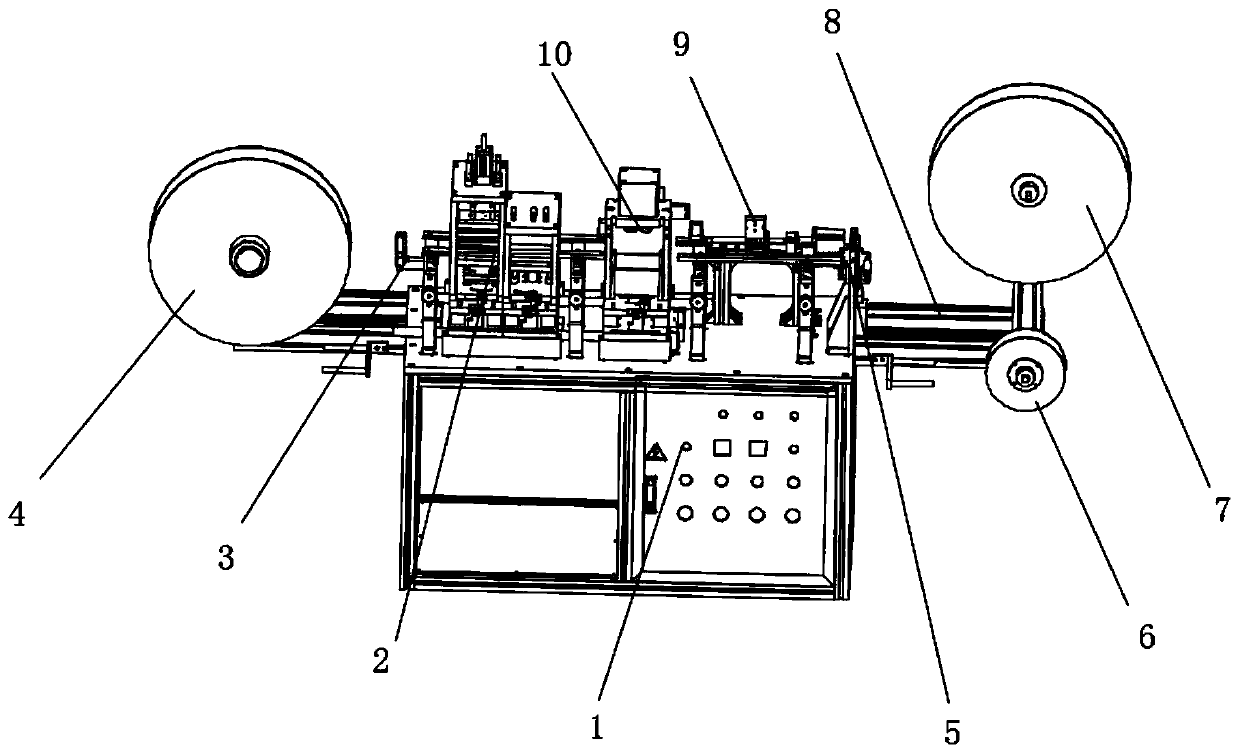

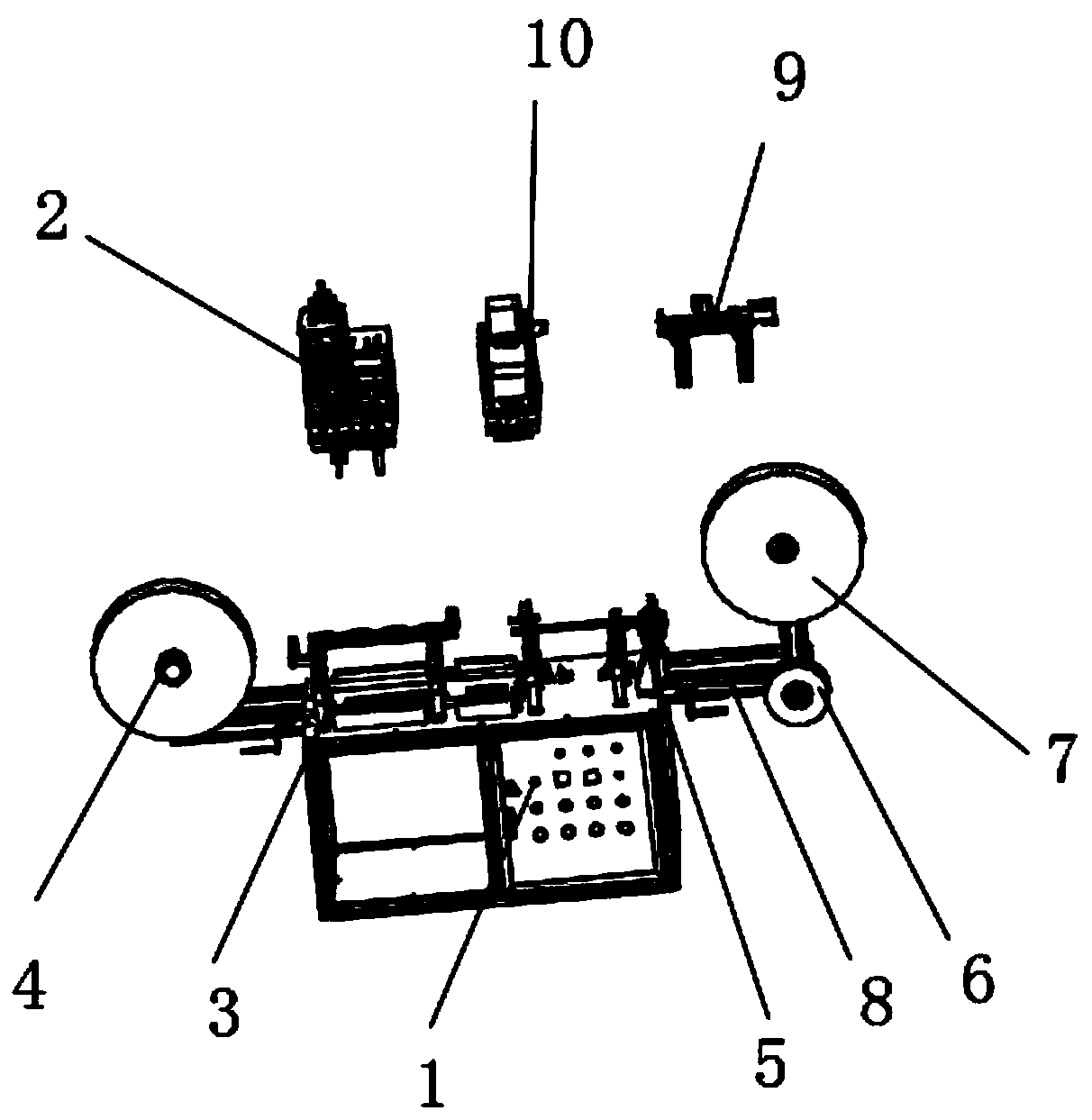

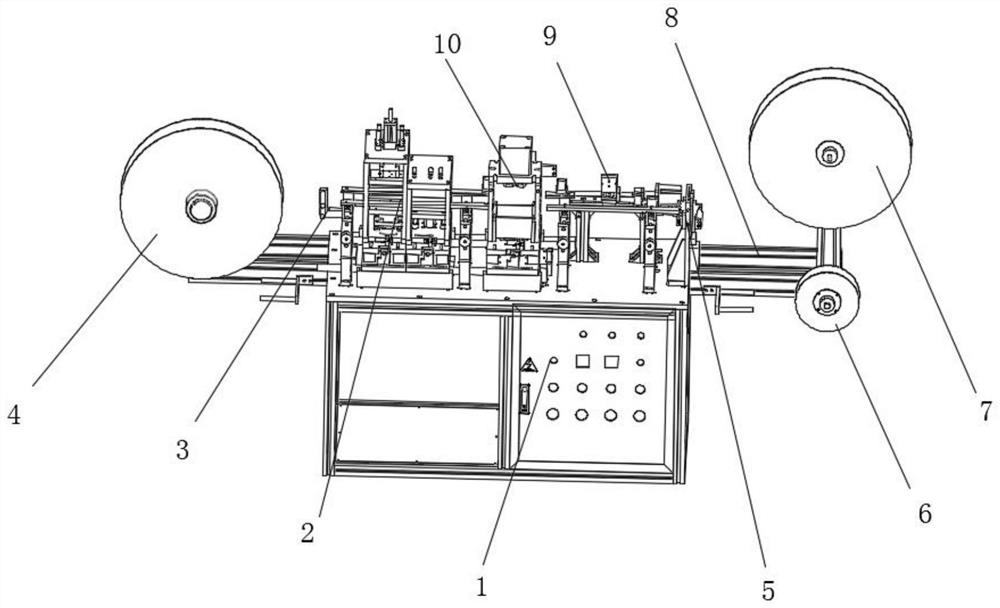

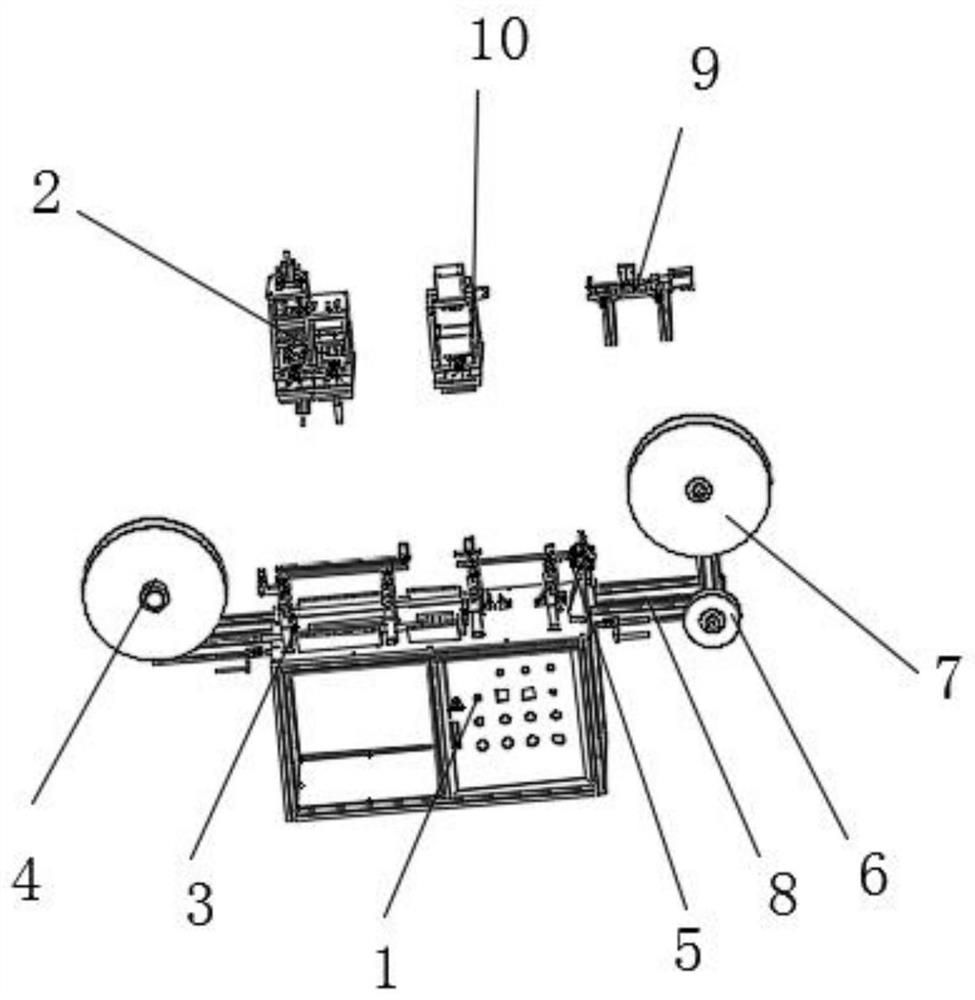

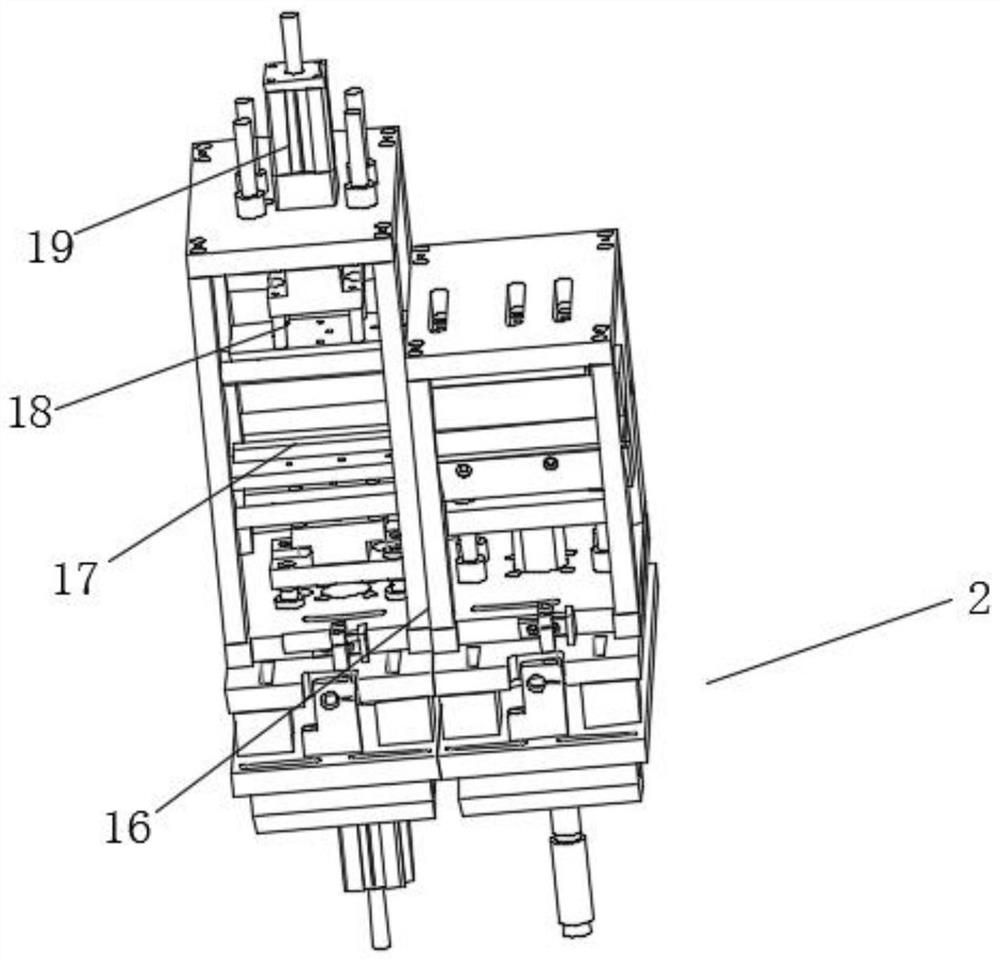

Waterproof tent cloth good in gas permeability and production device thereof

ActiveCN110566034AImprove antibacterial propertiesGood flexibilityMechanical cleaningStain/soil resistant fibresBiochemical engineeringCotton fibre

The invention discloses waterproof tent cloth good in gas permeability and a production device thereof. The tent cloth comprises a base cloth layer and a fabric layer arranged on the base cloth layer.The base cloth layer is woven from warps and wefts in an interwoven manner. The fabric layer is aramid fiber fabric. The tent cloth is manufactured through the following steps that the warps and thewefts are placed on a weaving loom to be woven, and the base cloth layer can be obtained; and impurities adhering to the surface of the aramid fiber fabric are removed. According to the waterproof tent cloth good in gas permeability and the production device thereof, the warps, composed of flax fiber containing insect and bacterium removal solvent and high-lightproof-performance fiber threads, andthe wefts, composed of bamboo charcoal fiber and cotton fiber, are woven into the base cloth layer, the flax fiber, the high-lightproof-performance fiber threads, the bamboo charcoal fiber and the cotton fiber all have good antibacterial performance, and therefore the tent cloth can effectively remove bacteria and repel mosquitoes, materials which are used are environment-friendly, and the waterproof tent cloth and the production device thereof conform to green production.

Owner:安徽嘉明新材料科技有限公司

Flame-retardant high-weatherability high-strength electric threading pipe and preparation method thereof

InactiveCN107286540AImprove mechanical propertiesExtended service lifeTubular articlesChemistryFire retardant

The invention discloses a flame-retardant high-weatherability high-strength electric threading pipe. The threading pipe comprises the following raw materials by weight: 55-65 parts of chlorinated polyvinyl chloride resin, 24-28 parts of styrenic thermoplastic elastomer, 1-3 parts of a lubricant, 10-14 parts of a compound flame retardant, 4-6 parts of a coupling agent, 3-5 parts of a compound barium-zinc stabilizer, 8-10 parts of an anti-cracking fibers, 2-4 parts of a compound insecticidal and antibacterial agent, 6 -8 parts of a filler, 7-11 parts of a processing aids and 12-16 parts of methyl methacrylate. The threading pipe provided by the invention has the advantages of excellent indexes of tear strength, tensile strength and elongation at breakage, good resistance to aging, hot and cold impact, microbes and the like, good fire resistance and flame-retardant effect, no smoke, no odor and long service life. Meanwhile, according to a preparation method for the threading pipe, the raw material used in the method are safe, reliable, harmless to environment and low in cost; the method is easy to operate and suitable for industrial production; so the preparation method has high practical value and good application prospects.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

A Method of Seedling Breeding of Fritillaria

InactiveCN106489470AFull of nutritionMeeting nutritional needsBiocideBio-organic fraction processingFertilizerChlamydomonas

The invention relates to a method for seedling raising of Fritillaria, which comprises the following steps: (1) the humus-containing loam soil or sand is selected as the nursery land of Chlamydomonas subspecies; (2) the land of the control tiger are strewed by Pesticide 1- 2kg; (3) 15- 20 days later, the land is made to the ridge, the base fertilizer are spread on the ridge, and then soil, cover the base fertilizer, level the land, and finally cover with 1cm- 1.5cm mountain (5) to keep the soil moist, until spring emergence, cover density of 50 after emergence- 60 sun-shade net.(4) the pretreatment of seeds are sprinkled on the ridge, the seeds are covered with shrimp, pine and cooked soil; 60 shade net; (6) Miao long 3cm after every 20-25 days fertilizer once, fertilizer in accordance with the 300kg per mu, according to the amount of 5kg per acre, 45-60 days spraying foliar fertilizer once. The seedling rate of the seedling is less than 4%, and the rate of insects is less than 1.5%, and the germination rate is 90.2%.The incidence rate is less than 3.5%, the seedling rate is 93.4% , bulb weight to 1.5g, much higher than the existing nursery method.

Owner:YULONG JINWANG CHINESE MEDICINAL HERBS PLANTING CO LTD

Insecticidal oil emulsion

InactiveCN1628519ALow costIncrease the insecticidal mechanismBiocideAnimal repellantsActive componentOil emulsion

The invention relates to a pesticide, in particular a pesticide of missible oil preparation using plant extractive pyrethrin as the active component, which comprises (by weight ratio) pyrethrin 2-15%, alkylbenzene sulfonate 1.5-60%, synergistic agent 4-30%, emulsifying agent 10-20%, anti-oxidant 0.1-5.0%, and balancing dissolvent. The pesticide has fine prevention and curing effect for multiple kinds of insects.

Owner:李鹏飞

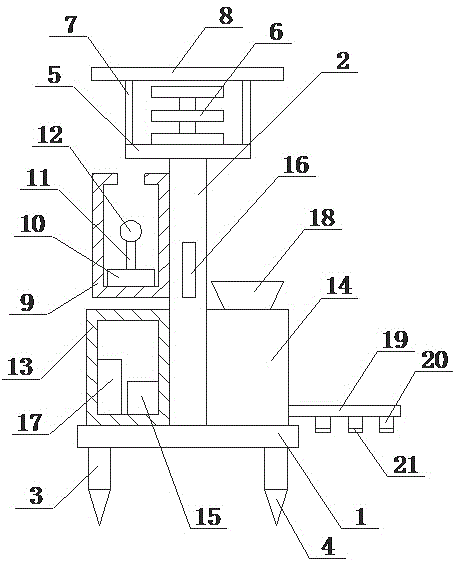

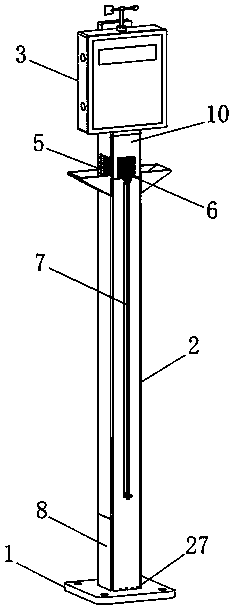

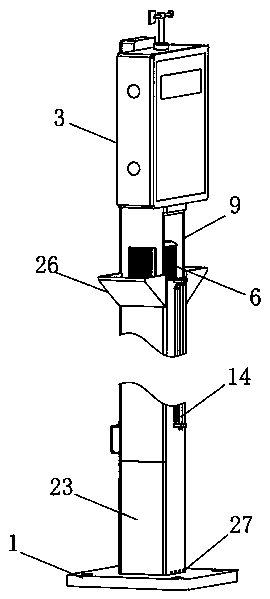

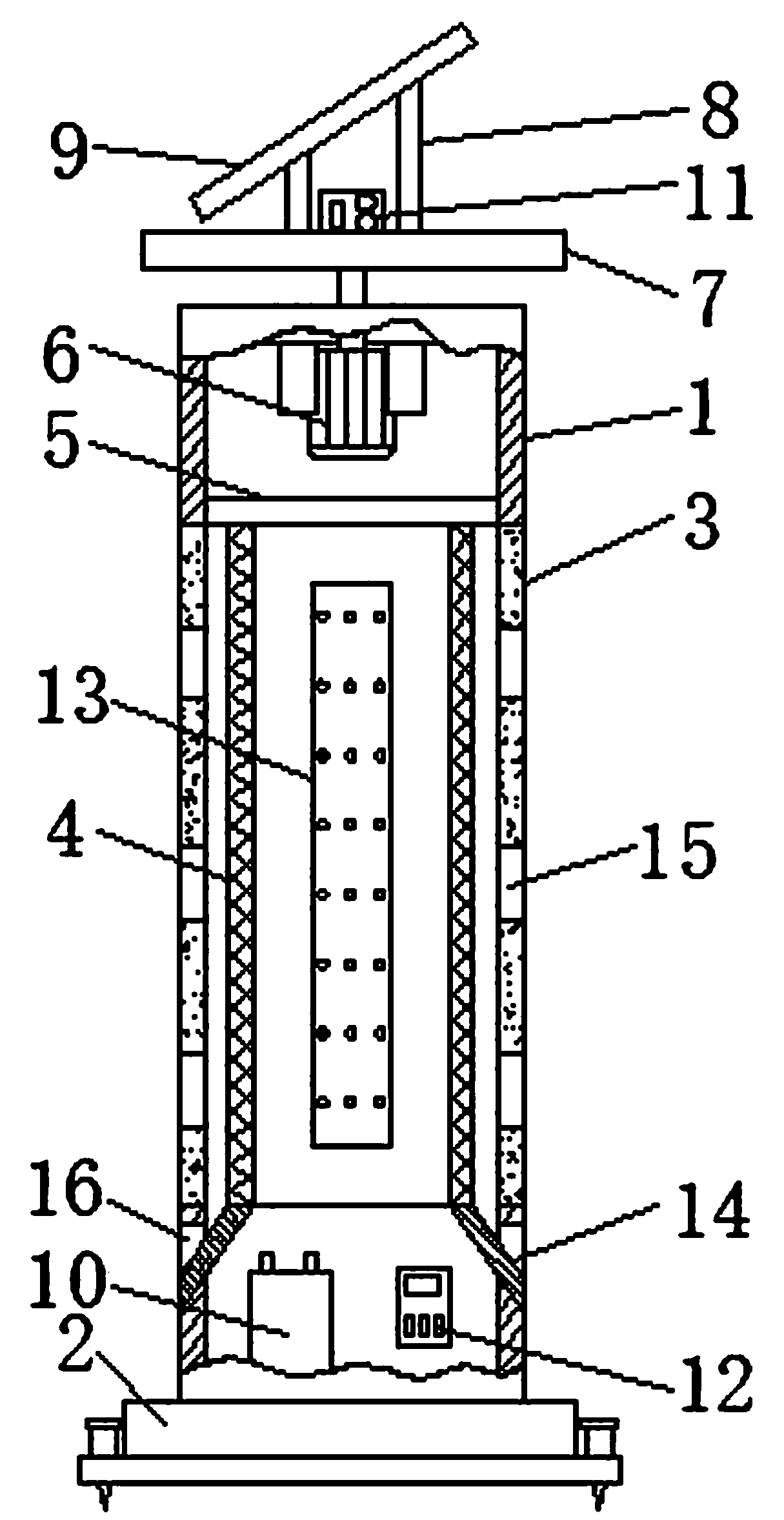

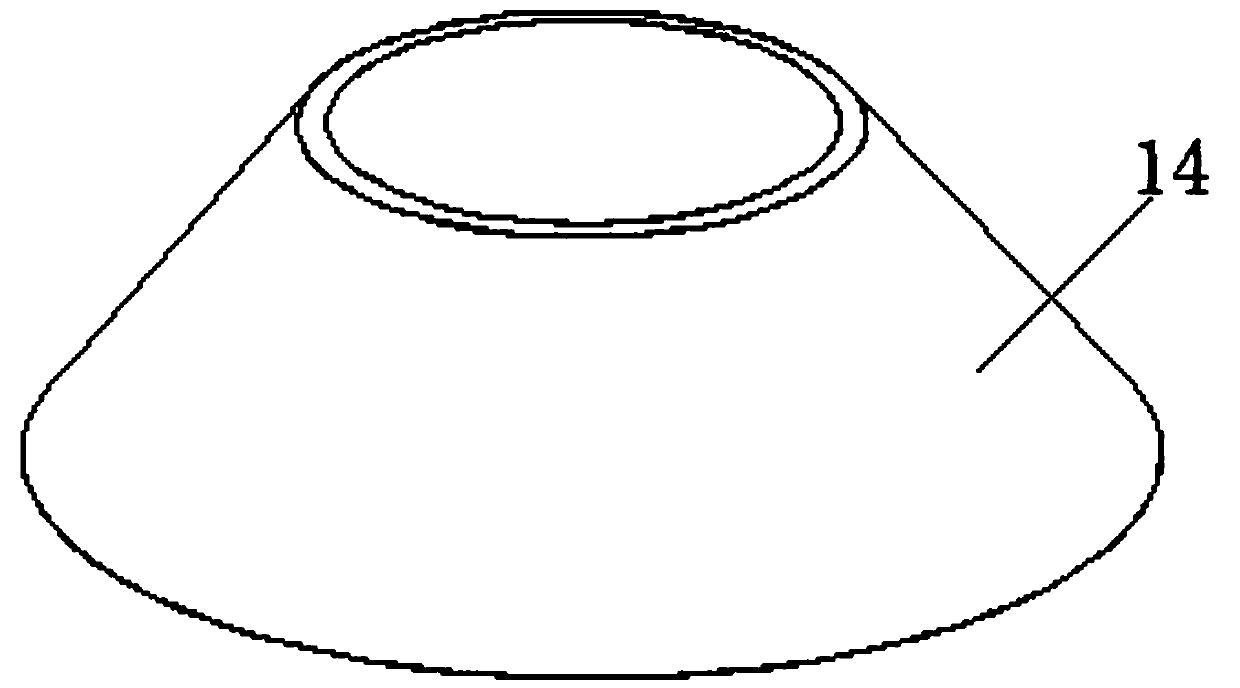

Deinsectization type garden energy saving lamp

InactiveCN105570783ASave electricityEffective against insectsLighting support devicesGeneral water supply conservationEngineeringRainwater harvesting

The invention discloses a deinsectization type garden energy saving lamp. The deinsectization type garden energy saving lamp comprises a base, and a stand column arranged on the upper surface of the base; an extension rod is arranged on the lower surface of the base; a steel needle is arranged on the lower surface of the extension rod; three sets of illumination lamps are distributed at the top of the stand column up and down in sequence through mounting discs; lamp covers are arranged on the upper surfaces of the mounting discs through connecting rods; a deinsectization box with an access port in the top is arranged in a position, near the top, of the side surface of the stand column, and is produced by glass; a water tank is formed in the bottom in the deinsectization box; a trap lamp is arranged in the water tank through a support rod; an electric control box and a water box are respectively arranged on the upper surface of the base; a timer and a power supply are respectively arranged in the electric control box; a rainwater collecting funnel communicated with the internal of the water box is arranged at the top of the water box; a water outlet pipe communicated with the internal of the water box is arranged in a position, near the bottom, of the side surface of the water box; and water droppers are uniformly distributed on the water outlet pipe. The deinsectization type garden energy saving lamp can kill mosquitoes when saving energy.

Owner:CHENGDU PUJIANG KEXIAN TECH

Prevention and control method of long-horned beetles for macadamia

The invention discloses a prevention and control method of long-horned beetles for macadamia. Aiming at tree trunks attacked by long-horned beetle larvae, adopted are procedures of applying microbialbacterial manure to attacked fruit trees, pruning attacked branches, finding latest bored holes from the attacked parts of the trees and applying insecticide, conducting stem spraying from the trunk root parts to fork parts of the fruit trees, using absorbent cotton balls to block holes of the long-horned beetles, covering the parts, subjected to stem spraying, of the tree trunks with straw ropes,spraying pest-killing and bacteria-killing agent liquid to the tree trunks and root parts of the whole fruit trees, timely removing the attacked trees and dead branches, and meanwhile using phagostimulant to trap the long-horned beetle adults. Comprehensive prevention and control are conducted by combining physical prevention and control with chemical prevention and control, so that the attackingrate of the long-horned beetles is lowered to 0.2% or below, the yield of nuts is obviously increased, and good economic benefit is obtained.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Special insecticide for pineapples

InactiveCN105707155AEffective against insectsEfficient killingBiocideDead animal preservationBiotechnologyQuisqualis indica

The invention discloses a special insecticide for pineapples. The special insecticide is prepared from following raw materials in parts by weight through decoction with water: 12-15 parts of common carpesium fruit, 12-18 parts of semen torreyae, 10-14 parts of Cyrtomium rhizome, 8-15 parts of aloe, 8-12 parts of pharbitis seed, 6-12 parts of Sichuan pepper, 5-8 parts of szechwan chinaberry bark, 6-8 parts of areca seed, 4-6 parts of stemona root, 3-8 parts of gleditsia sinensis, 3-6 parts of tripterygium wilfordii, 2-4 parts of hairyvein agrimonia herb, 2-5 parts of Quisqualis indica, 1-3 parts of gemma agrimoninae and 1-2 parts of Laccocephalum mylittae. The special insecticide for the pineapples has the following beneficial effects: a decocted fluid obtained by decocting the traditional Chinese medicine components with a reasonable method is sprayed, a natural medicine protection layer can be formed on the surface of the fruit, pests on the surface of fruit bodies are effectively killed, and meanwhile, pest breeding can be prevented effectively through odor emitted by the medicines.

Owner:LIUZHOU XINXIN FRUIT PLANTATION

Special pesticide used for blueberries

InactiveCN105851094AEffective against insectsEfficient killingBiocideDead animal preservationPumpkin seedAgrimonia eupatoria

The invention discloses a special pesticide used for blueberries. The special pesticide is prepared through decocting raw materials in water, and the raw materials comprise, by weight, 10-20 parts of sophora flavescens, 12-18 parts of Chinese torreya, 10-14 parts of Cyrtomium fortunei, 8-15 parts of aloe, 8-12 parts of morning glory seeds, 6-12 parts of Chinese prickly ash, 6-10 parts of Fructus Toosendan, 6-8 parts of betel nut, 4-6 parts of Radix Stemonae, 3-8 parts of Gleditsia sinensis, 3-6 parts of Common Threewingnut Root, 2-4 parts of Agrimonia eupatoria, 2-5 parts of Quisqualis indica, 1-4 parts of pumpkin seeds and 1-2 parts of Omphalia. A decoction obtained after decocting all traditional Chinese medicinal components through a reasonable method is sprayed to form a natural medicine protection layer on the surfaces of fruits and effectively kill pests on the surfaces of the fruits; and medicines release smell, so breeding of the pests is effectively prevented.

Owner:LIUZHOU XINXIN FRUIT PLANTATION

Apple pesticide

InactiveCN105341005AEffective against insectsNo side effectsBiocideAnimal repellantsChlorpyrifosChinese Chive

The invention discloses an apple pesticide. The apple pesticide is prepared from, by mass, 50-70 parts of garden sorrel, 18-22 parts of carbendazim wettable powder, 40-60 parts of yellow tengen, 50-60 parts of bitter gourd, 40-50 parts of neem, 80-90 parts of sophora alopecuroides, 6-8 parts of Chinese chives, 80-90 parts of luffa stems, 30-50 parts of chlorpyrifos, 10-14 parts of watermelon vines, 50-60 parts of chrysanthemum lipid and 1000-1400 parts of water. According to the plant pesticide, various apple tree injurious insects can be effectively killed during the apple fruit bearing period, no side effect is generated to apples, the cost is low, and economic benefits can be improved.

Owner:QINGDAO YUXING GRAPHITE MATRIX

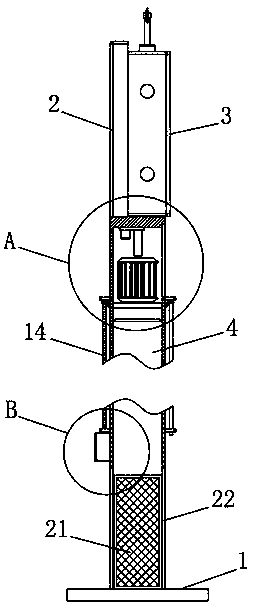

Air quality monitoring system

InactiveCN111189976AProblems avoiding nighttime collisionsEfficient insecticideAnalysing gaseous mixturesInsect catchers and killersContinuous useRainwater harvesting

The invention discloses an air quality monitoring system. The system includes a fixed base, a supporting stand column is fixed on the fixed base, a monitor main body for monitoring the air quality ismounted at the top end of the supporting stand column, a longitudinal waste discharge channel is formed in the supporting stand column, the air quality monitoring system is different from the prior art, a pest killing mechanism based on a trap lamp technology Is adopted, the trap lamp adopts a visible light source, while high-efficiency insect trapping is ensured, a lighting or warning effect canalso be achieved at night, the problem of night collision of the supporting column is avoided, the supporting column is internally equipped with the longitudinally-communicated longitudinal waste discharge channel, so that winged insect corpses can be conveniently treated, meanwhile, the longitudinal waste discharge channel can be automatically cleaned at regular intervals, accumulation and blockage are avoided, and a rainwater collecting structure is also arranged to assist cleaning, therefore effective insect killing is guaranteed, and efficient monitoring of the monitor main body in a continuous use process is guaranteed.

Owner:宁波博之越环境科技有限公司

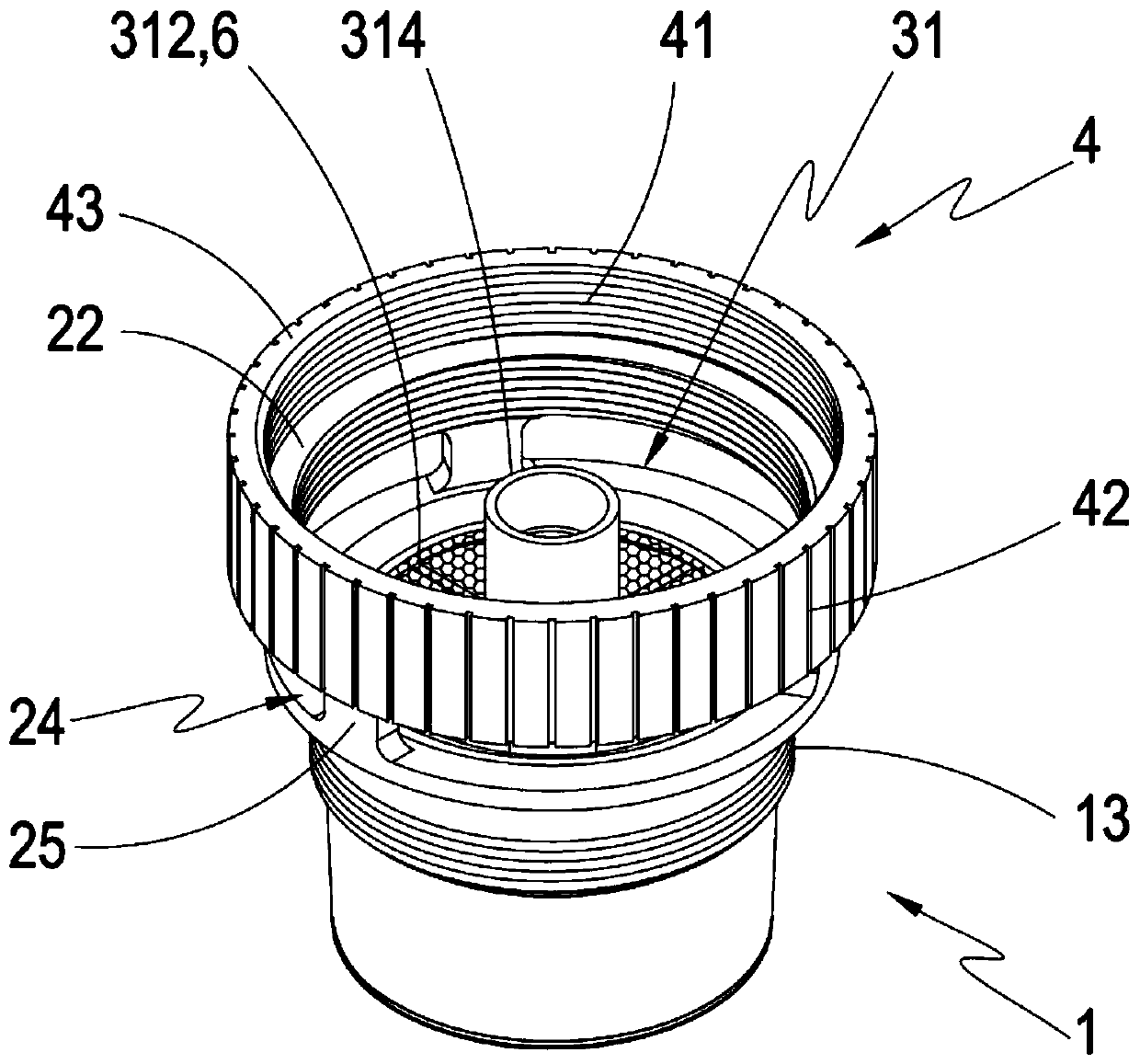

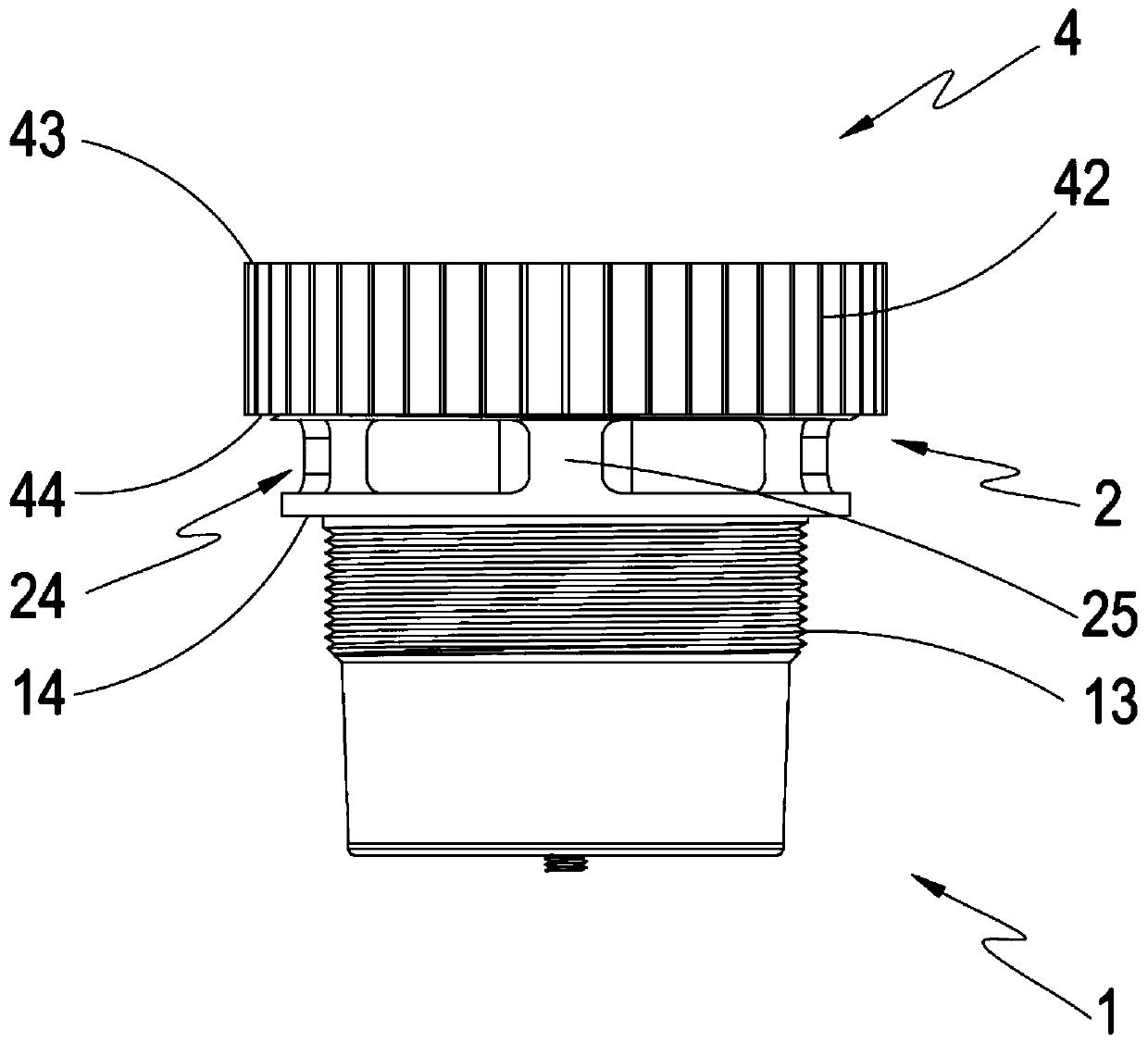

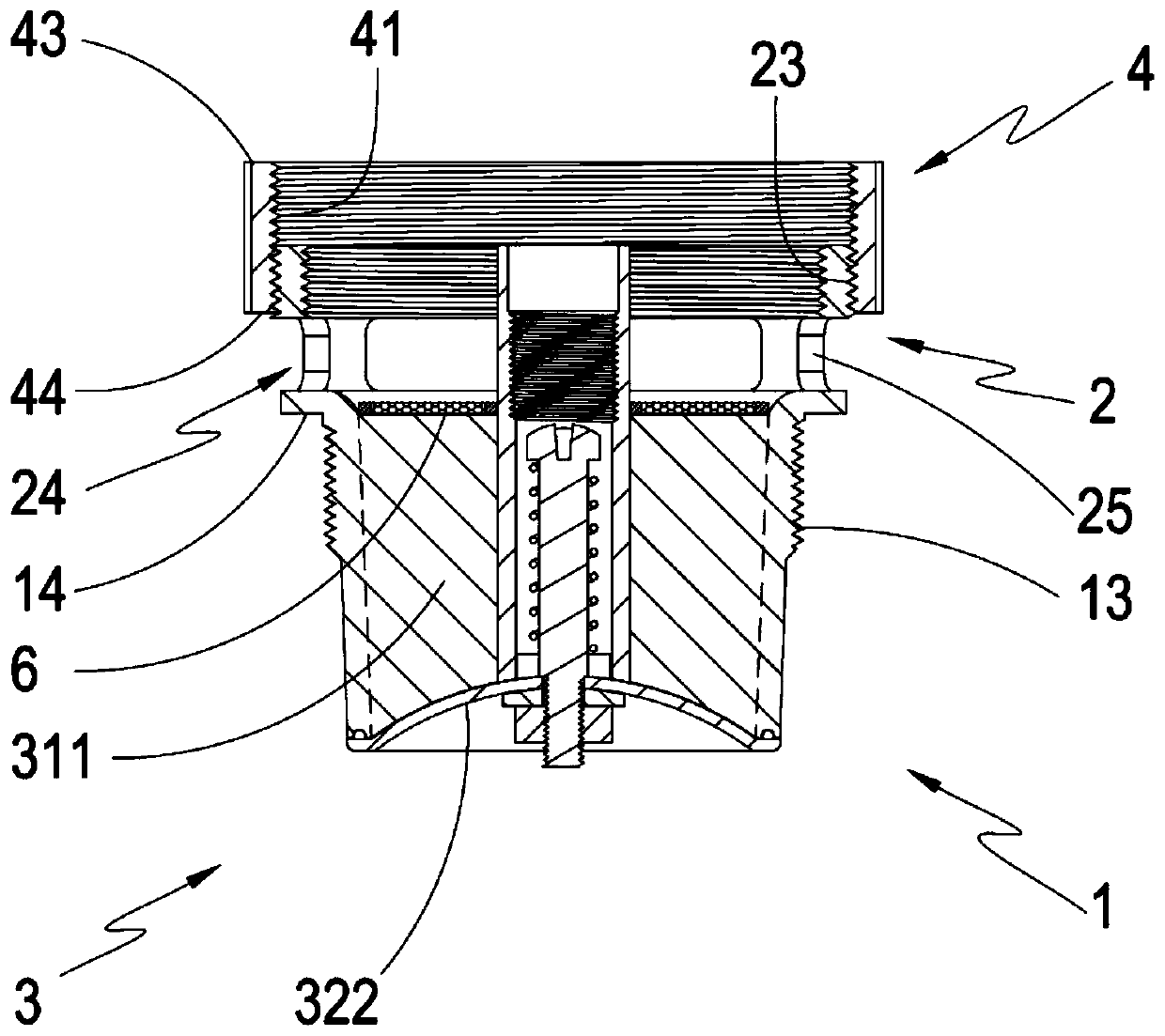

Multifunctional floor drainer

ActiveCN109930676AControl water storageAvoid blockingSewerage structuresControlled drainageStops device

The utility model discloses a multifunctional floor drainer, comprising a drainer body with a body lower end water outlet part, a body upper end extension body arranged on the drain body and providedwith an extension body side water inlet part, an automatic deodorizing and stopping device movably arranged on the drain body, and a control switch movably arranged on the body upper end extension body; the drainer body is combined and fixed on a water draining base to arrange a base accumulating portion, and the extension body side water inlet part can be selectively opened and closed by operating the control switch, so as to control whether the base accumulating part stores water, and when liquid or the like is discharged from the body lower end water outlet part, the weight of the liquid enables an automatic deodorization and non-return device to be in an open state, and the automatic deodorization and non-return device returns to a closed state after the liquid is discharged; thereby the multifunctional floor drainer achieve the practical advancement of freely adjusting and controlling drainage and water storage functions, and effectively preventing insects, deodorizing, and preventing violent flushing and water backflow.

Owner:苏宣维

Planting method to promote spring tea to produce in advance

InactiveCN108718880APromote growthHarvest earlyFertilising methodsCultivating equipmentsTrace elementSpray irrigation

The invention provides a planting method to promote spring tea to produce in advance and belongs to the technical field of tea tree planting. The planting method comprises the steps of selecting a garden, preparing the garden, applying fertilizers, planting tea trees, managing fertilizers and water, and harvesting. Base fertilizer is applied during growth of tea trees; budding acceleration fertilizer and leaf fertilizer are applied before tea picking; the double actions and the base fertilizer cooperate, ultraviolet lamp irradiating and manual spray irrigation are utilized, and therefore, it is effectively ensured that sufficient nutrients and trace elements are attained in the whole tea tree growth process, bud growth is promoted, silver tip white tea can be harvested in advance, and theyield is increased.

Owner:广西凌云县凌春农业商贸有限责任公司

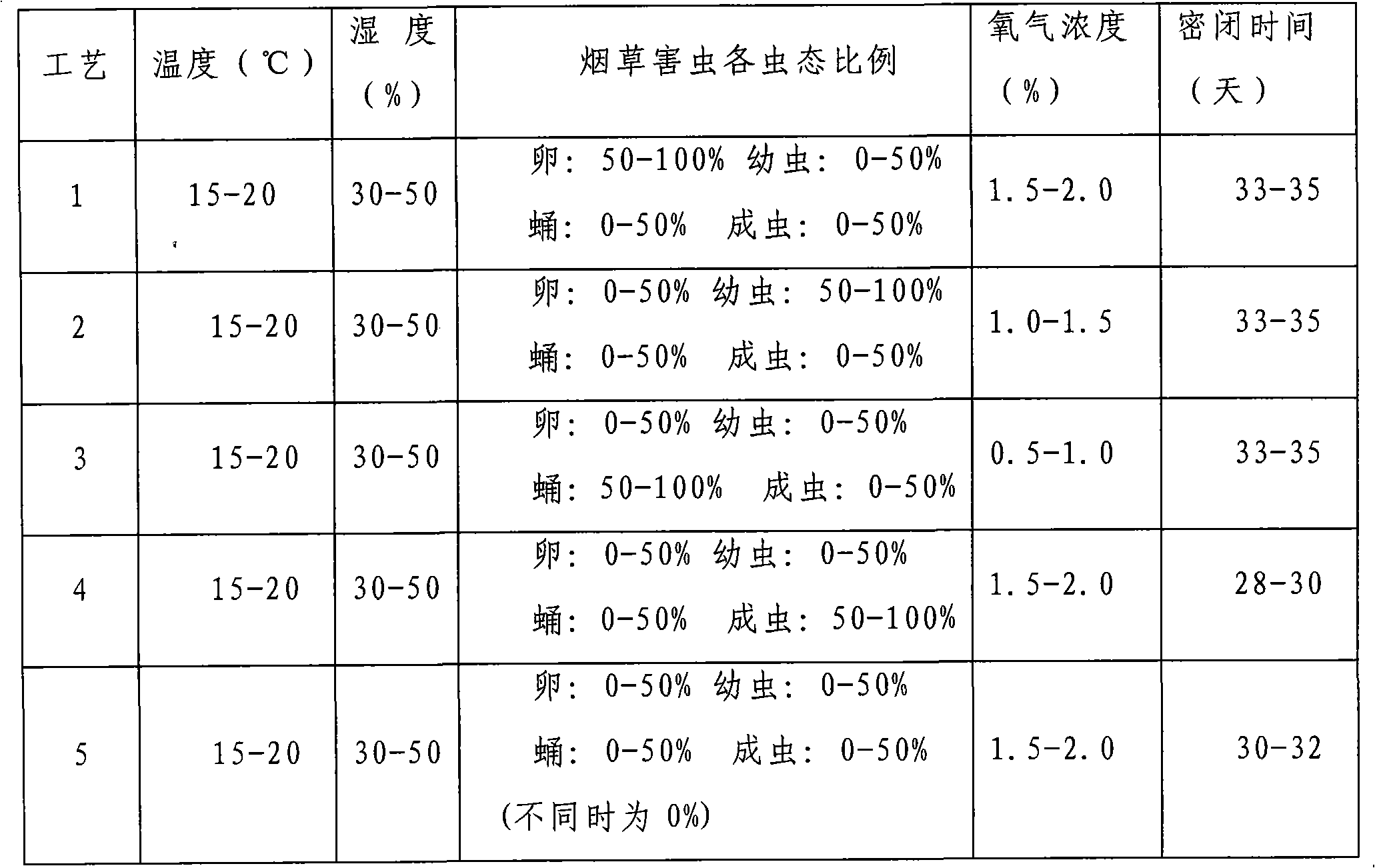

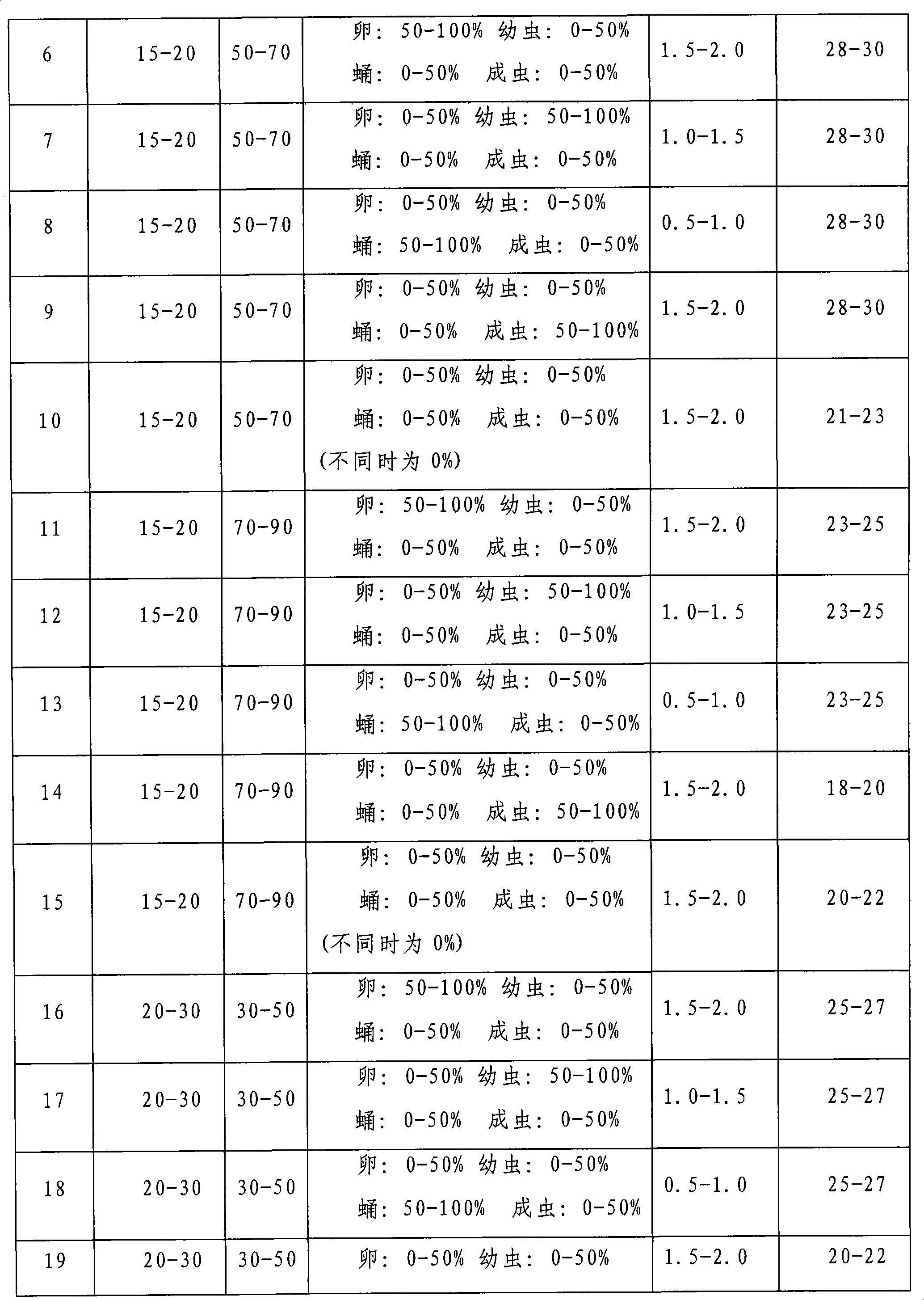

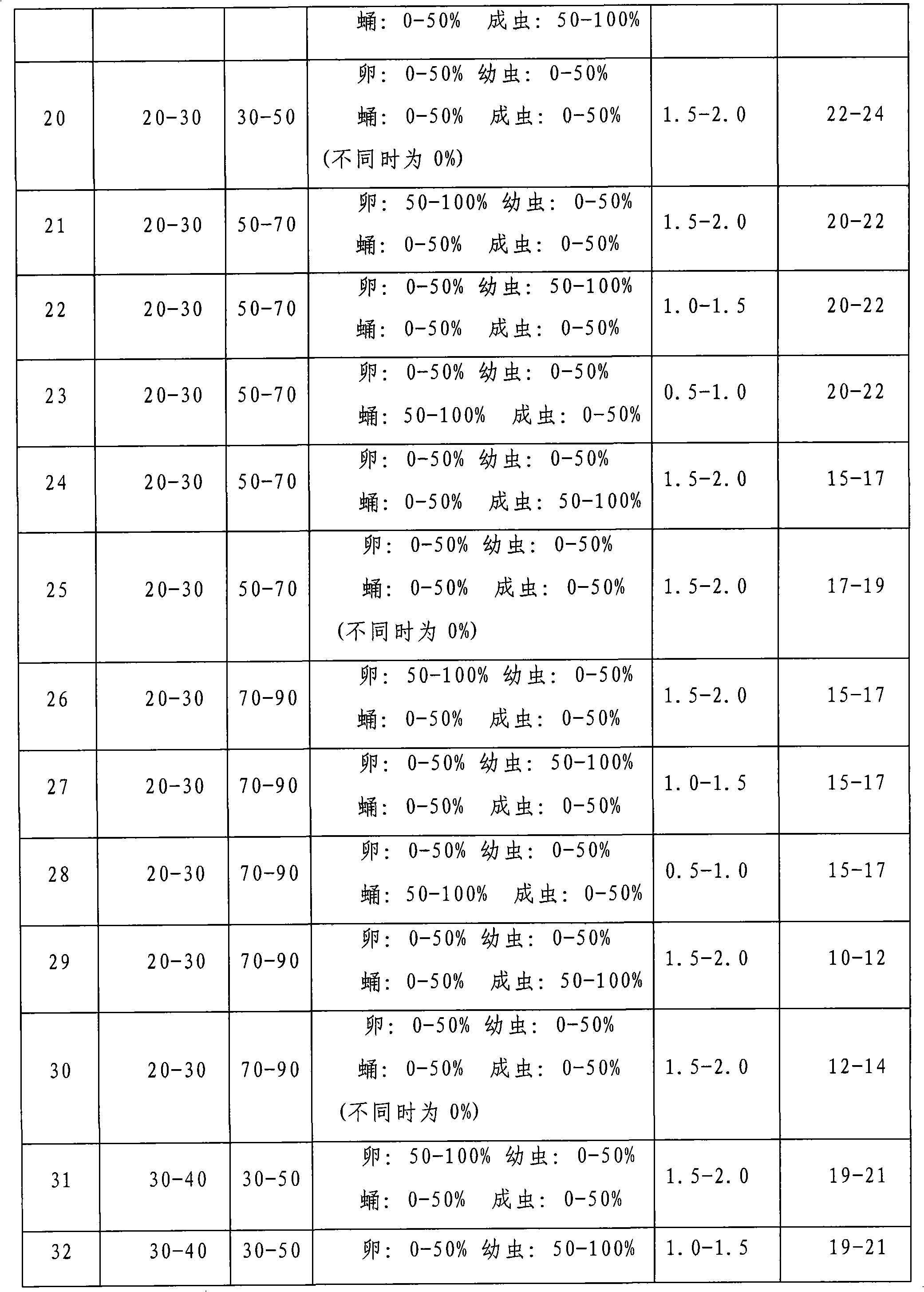

Method for killing injurious insects of tobaccos under condition of low oxygen

ActiveCN102871217AQuickly and thoroughly kills insectsHas practical valueTobacco treatmentZoologyLow oxygen

The invention provides a method for killing injurious insects of tobaccos under the condition of low oxygen. The method comprises the following steps of: (1) counting the number of the injurious insects of the tobaccos in different insect states in tobaccos, and computing the ratio of spawns, larvae and imagoes; (2) storing the tobaccos in hermetic space to form a hermetic stack, wherein an oxygen concentration tester, a thermometer and a hygrometer are arranged on the hermetic stack; (3) reducing the concentration of oxygen in the hermetic stack to be below 2 percent, and measuring temperature and humidity in the stack of the tobaccos; and (4) sealing the stack of the tobaccos at normal temperature under the condition of normal humidity for 5 to 35 days according to the concentration of the oxygen in the hermetic stack and the insect state ratio of different injurious insects. By the method, various injurious insects of different insect states in the tobaccos can be killed quickly without the influence on the mellowing quality of the tobaccos.

Owner:湖南华望熏蒸消毒有限公司

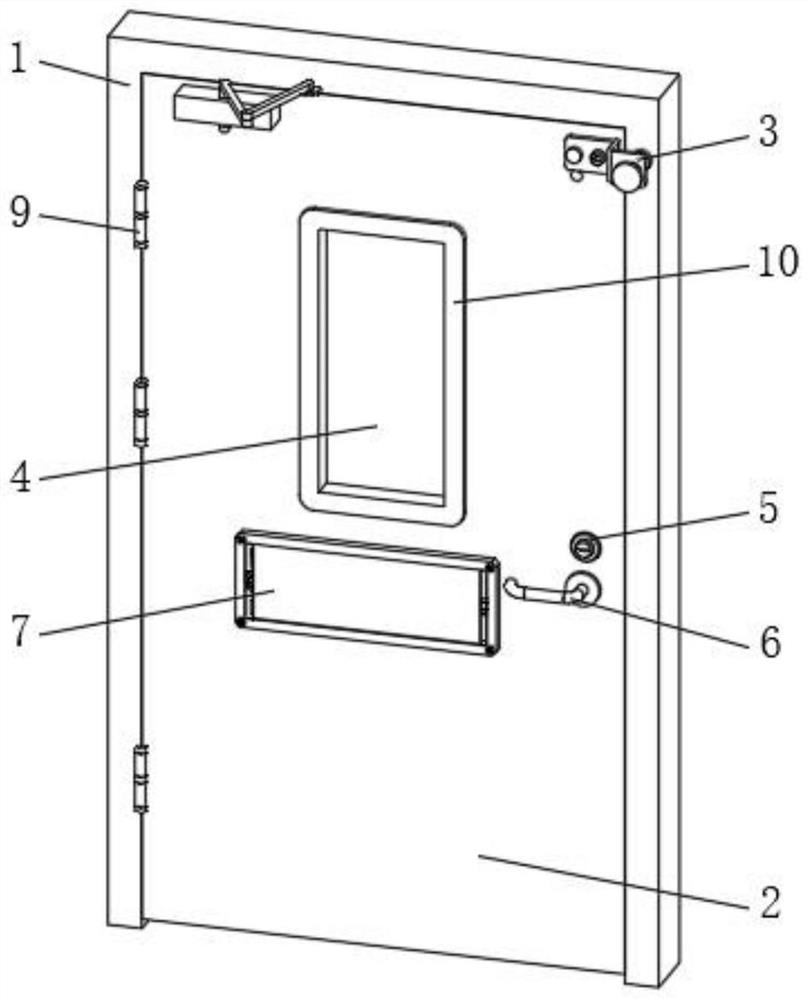

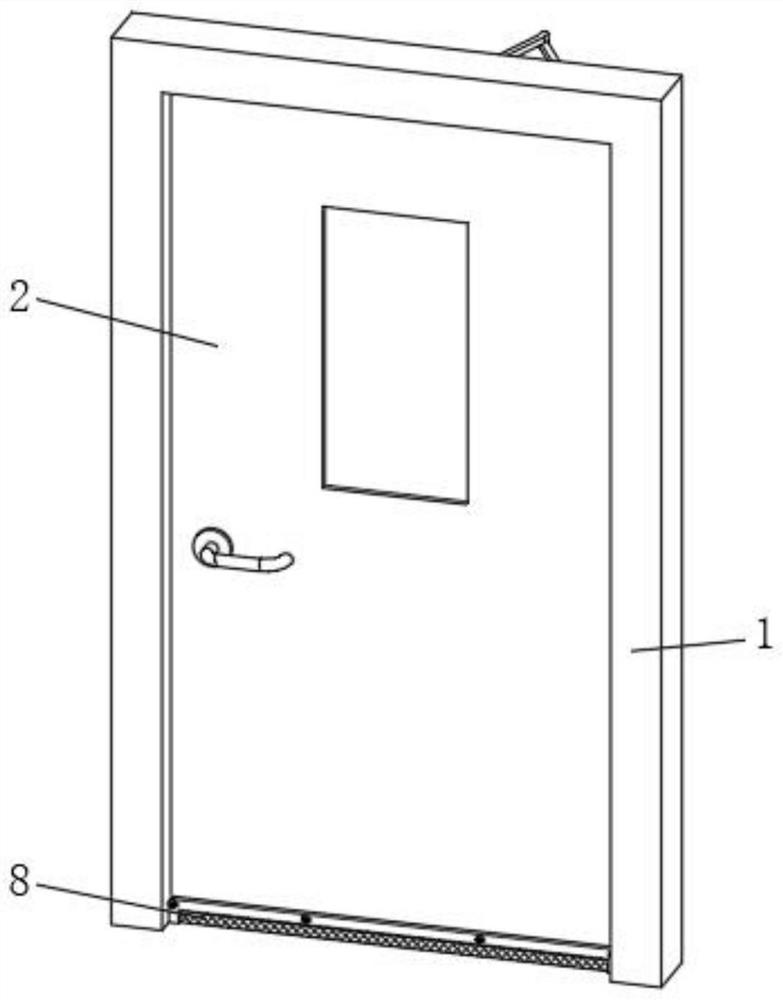

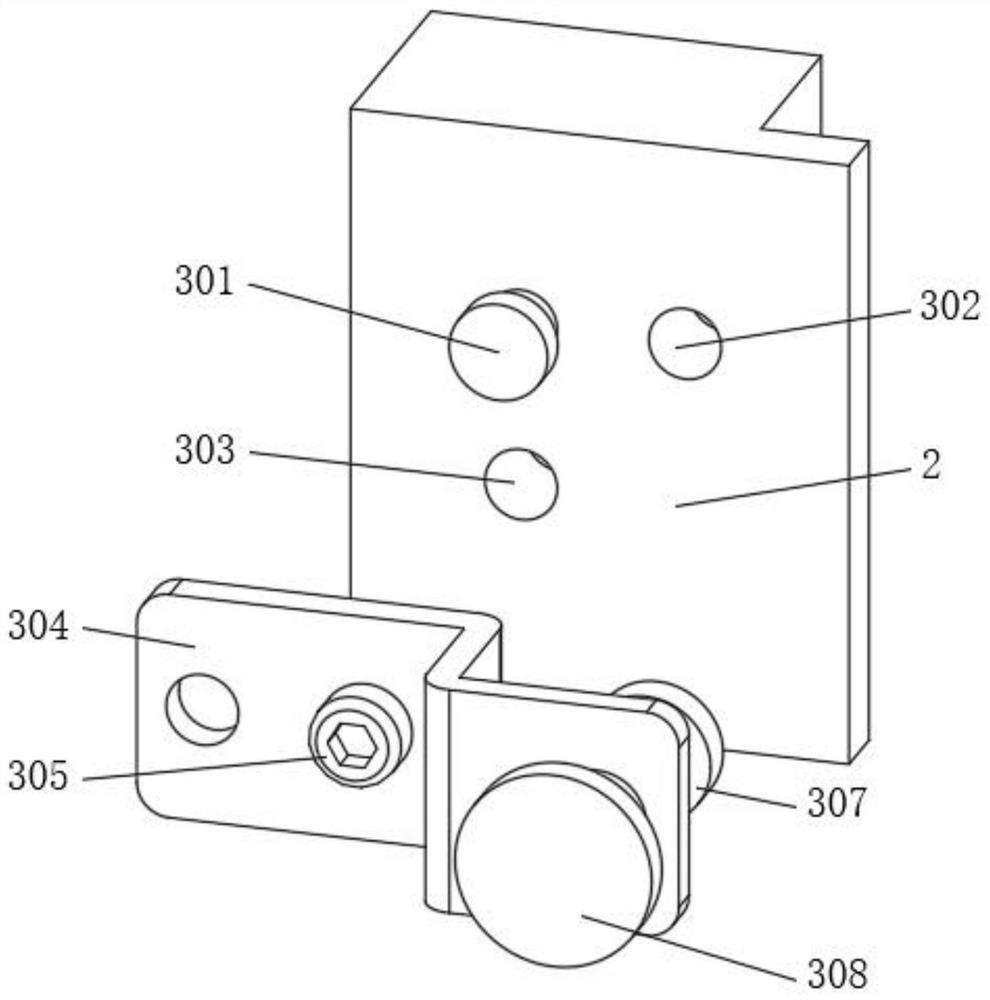

Composite fireproof door and manufacturing process

InactiveCN114320117AAvoid direct impactPlay a buffering effectFireproof doorsBuilding braking devicesMechanical engineeringIndustrial engineering

Owner:广东力尊建筑科技有限公司

Application of poria cocos ethanol extract to biopesticides

The invention discloses application of a poria cocos ethanol extract to biopesticides and particularly relates to application of the poria cocos ethanol extract to killing with poison of cotton bollworm and resistance to wheat glume blight and early blight of plants. The poria cocos ethanol extract provided by the invention is capable of effectively killing the cotton bollworm with poison and resisting the wheat glume blight and the early blight of plants, and the selection range of the biopesticides is broadened.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

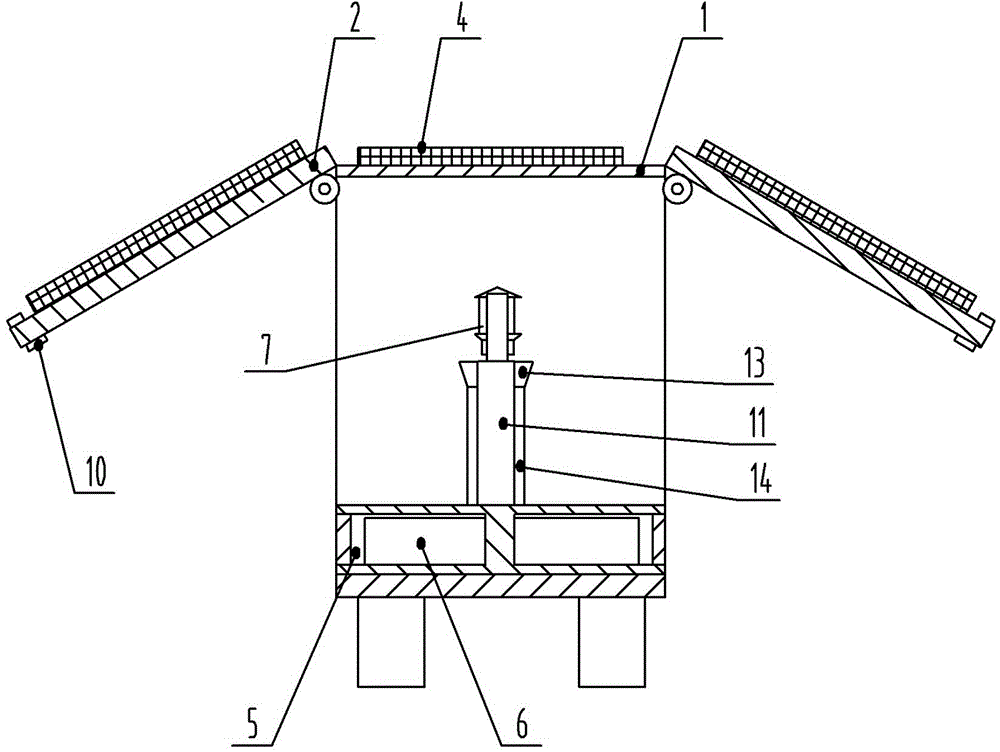

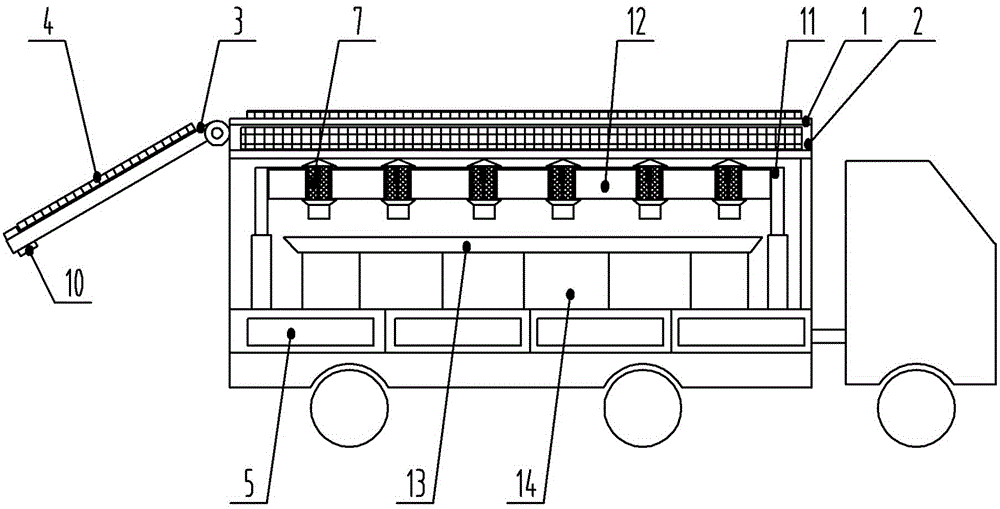

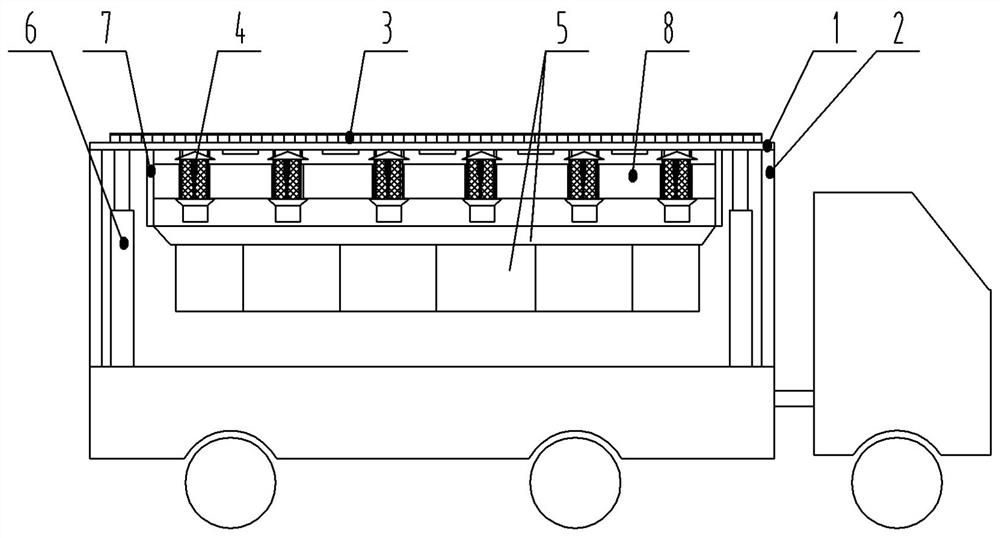

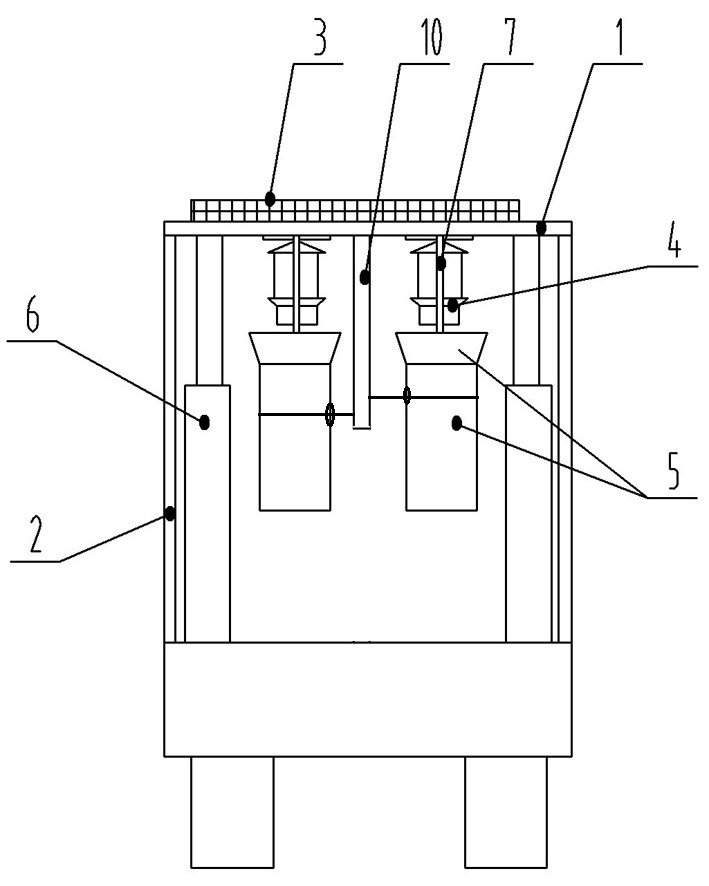

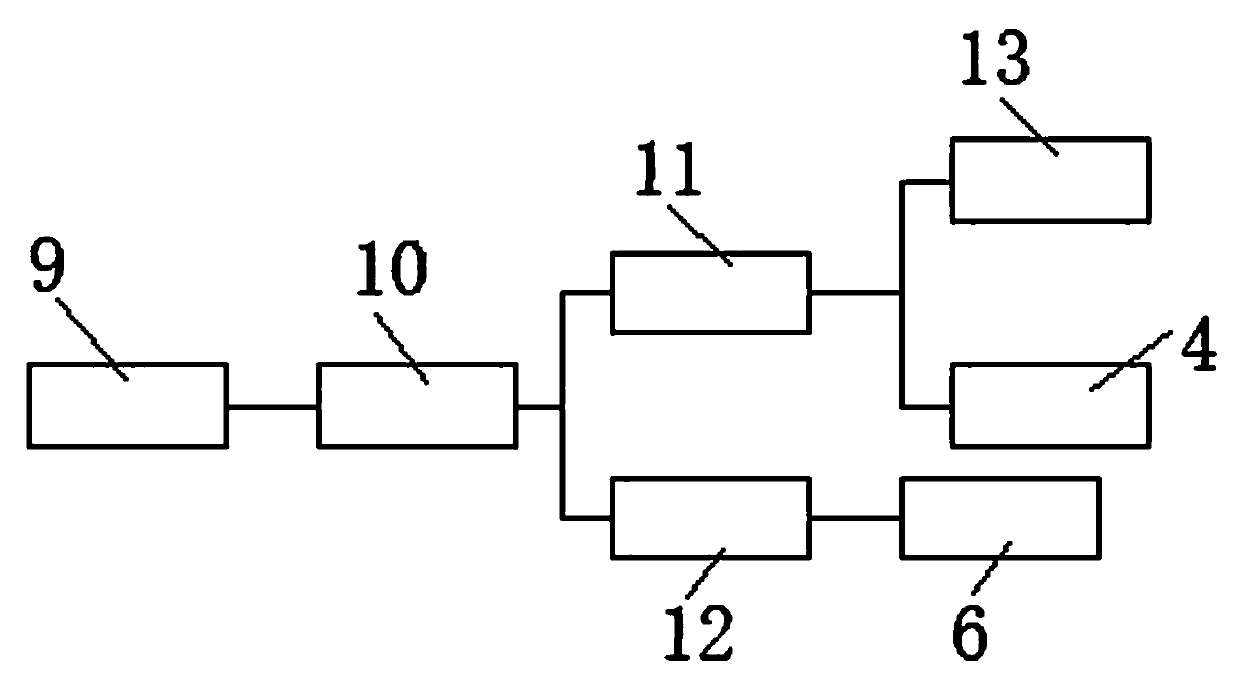

Mobile insecticide vehicle and manufacturing method thereof

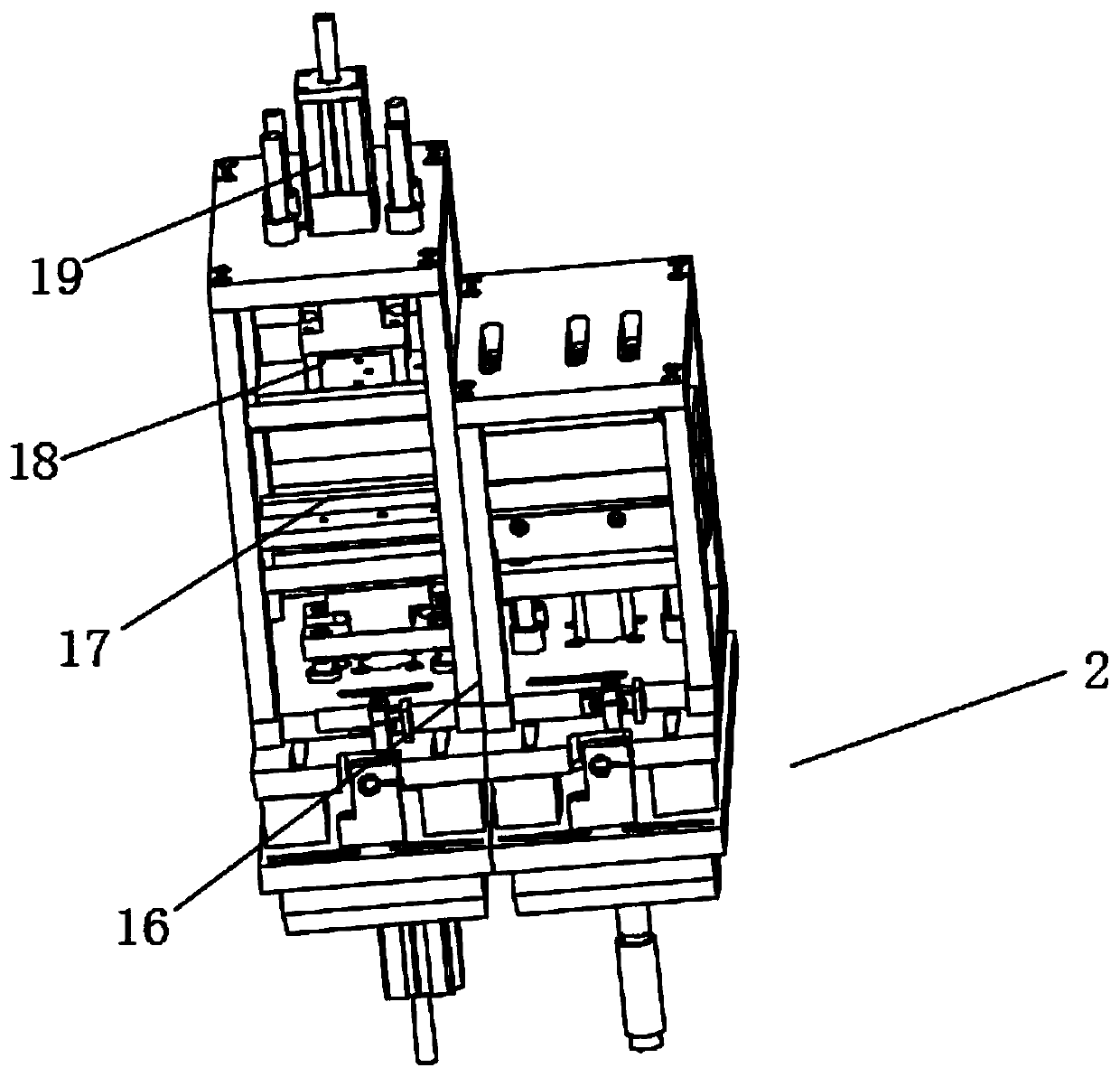

ActiveCN108124836BTo achieve the purpose of harm controlTo achieve the purpose of controlling the epidemicBatteries circuit arrangementsElectric powerAgricultural engineeringStructural engineering

The invention belongs to the technical field of insect prevention and control, and in particular relates to a mobile insect killing vehicle and a manufacturing method thereof. The compartment consists of a roof and side panels around the sides. The top panel is movably connected to the top of the side panels. Solar photovoltaic modules are embedded on the top surface of the roof panel. A battery compartment is installed on the lower surface of the roof panel. The insecticidal lamp is hoisted below the insecticidal lamp to provide an insect collecting tank and an insect collecting box, and the bottom of the roof is provided with a lifting adjustment structure, and the battery is electrically connected to the solar photovoltaic module and the insecticidal lamp respectively. In order to obtain this car, the solar photovoltaic module is embedded on the upper surface of the roof, and the battery compartment is arranged on the lower surface of the roof; It is hoisted under the roof in a row. In this way, the insecticide can be moved and powered by itself, the manufacture is convenient, the cost is saved, and the trapping and killing effect is good, so it is more suitable for popularization and implementation.

Owner:新乡市绿色园林新能源有限公司

Solar insecticidal street lamp for park

InactiveCN109724029AImprove playbackFree from infringementElectric circuit arrangementsLighting elementsGlass coverPower grid

The invention discloses a solar insecticidal street lamp for a park. The lamp includes a housing, the middle part of the housing is connected with a glass cover; an LED lamp is mounted in the glass cover; a motor is mounted at the upper part in the housing; the output end of the motor penetrates through the top of the housing; the output end of the motor is fixedly connected with a first supporting plate; a supporting frame is fixedly connected to the upper portion of the first supporting plate. A solar cell panel is installed above the supporting frame, a light-operated switch is arranged above the first supporting plate, a power grid is arranged on the inner side of the glass cover, the bottom end of the power grid is connected with a second supporting plate, a storage battery is arranged at the bottom end of the interior of the housing, and the storage battery is electrically connected to the solar cell panel. The lamp is novel in structure, the light receiving angle of the solar cell panel can be changed, more light can be absorbed and converted into electric energy, meanwhile, the lamp can effectively kill insects at night, and residents are prevented from being invaded by mosquitoes when walking in a park.

Owner:韦健宁

APG (alkyl polyglucoside) plant environmentally-friendly shampoo

InactiveCN102210644BReduce surface tensionStrong wetting powerCosmetic preparationsHair cosmeticsBiotechnologySkin irritant

Owner:董家华 +1

Production method bamboo strip side pressing bamboo board

InactiveCN101417457BJieba XiaoxianIncrease profitCane mechanical workingReed/straw treatmentWood veneerResist

The invention relates to a manufacturing method of bamboo boards by side standing pressing of bamboo chips, including the following steps: bamboo chips or bamboo stripes initially processed according to required sizes are put into a kiering pool to be brewed with boiling water or are placed into a kiering pool with insect-resist agents, mold preventing agents, bleachers or coloring agents to be brewed with boiling water or placed into a dip bleaching pool with bleachers or coloring agents to be dip-bleached; the bamboo chips or bamboo stripes are directly placed into an autoclave for high temperature steam and sulfuration; a resin adhesive is uniformly coated on bottom surfaces and surfaces of the dried bamboo chips or bamboo stripes; the glued bamboo chips or bamboo stripes are sent intoa hot-press to be hot-pressed until the glue is solidified; the chips or stripes are cooled to the normal temperature, then stored in a constant-temperature house for 30 days and then cut into finished products according to needed dimensions. The surfaces of the bamboo boards are natural textures formed by the lamination of sides of slices of bamboo chips and are beautiful without knots; the boards are larger in bearing capacity, little in gel content of finished products, more good for the environmental protection and hard to deform; and compared with the prior art, the method is high in efficacy, saves electricity, improves the utilization efficiency of original bamboos and saves cost.

Owner:赵斌

A kind of formula of natural shampoo and its preparation process

ActiveCN104814895BNo pollutionHas broad-spectrum antimicrobial activityCosmetic preparationsHair cosmeticsWater insolubleCyclodextrin

Owner:湖南红星盛康油脂股份有限公司

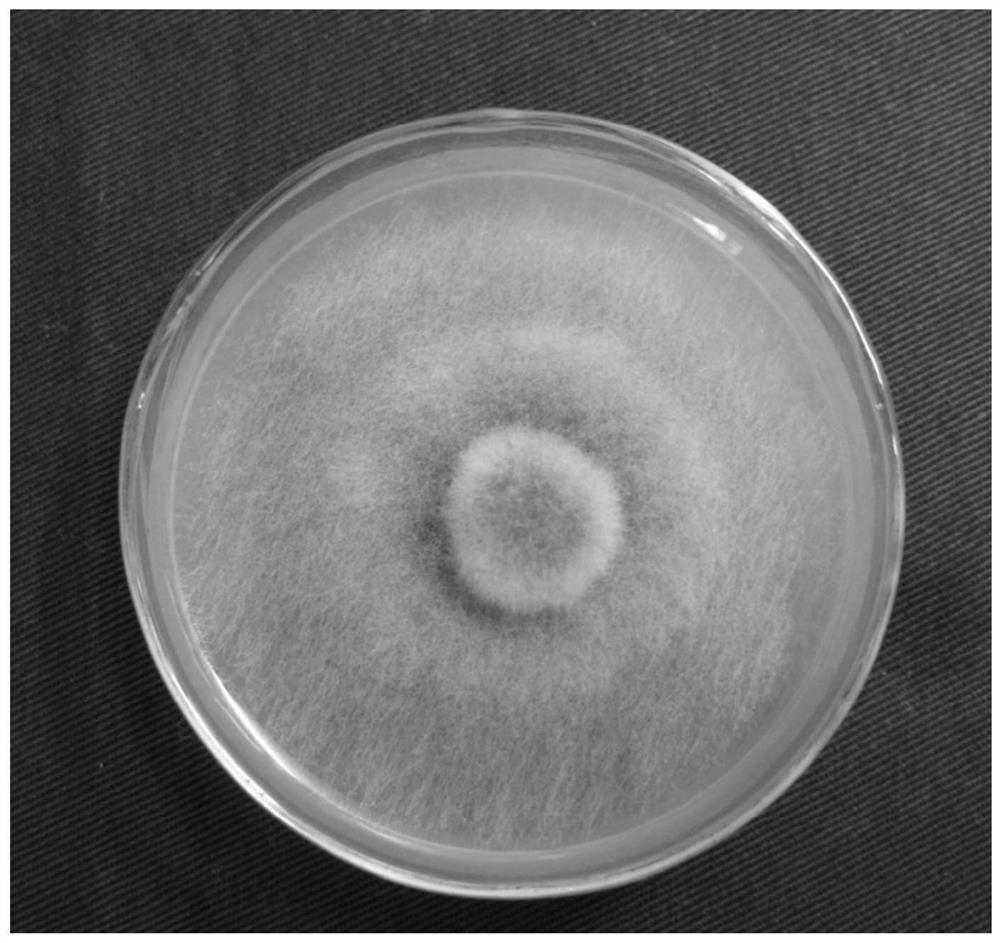

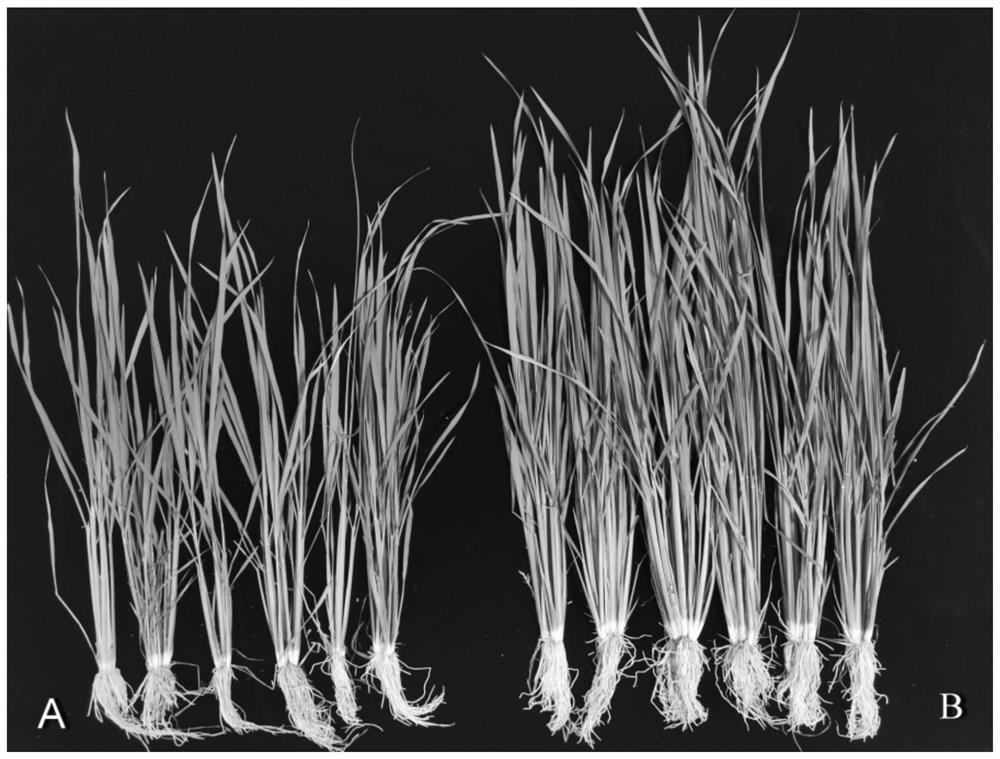

A crop growth-promoting and disease-resistant dse strain and its application

ActiveCN112280692BEffective against insectsPromote growthBiocidePlant growth regulatorsVerminPlanthopper

The invention relates to the field of biotechnology, in particular to the DSE fungal strain J2PC4 and its application. The invention discloses a strain Phialocephala fortinii J2PC4 with a deposit number of CGMCC NO.20236. The strain has the properties of promoting the growth of rice, reducing the incidence of southern rice black-streaked dwarf disease, hindering the growth and reproduction of white-backed planthopper pests, and effectively preventing and controlling banana fusarium wilt. It is a DSE fungus with good growth promotion and disease prevention effects, which can be widely used in the field of biochemical fertilizers and biopesticides, effectively reducing the dependence of agricultural production on chemical pesticides and chemical fertilizers. Compared with the control, it can effectively promote the growth of rice, increase the biomass (dry weight) by 46.43%, effectively reduce the incidence of southern rice black-streaked dwarf disease by 11.70%, and increase the lethality of white-backed planthopper by 369.23%. The reproduction rate of white-backed planthopper was reduced by 26.73%, and the control effect on banana fusarium wilt reached 70.97%.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

A waterproof and breathable tent fabric and its production device

ActiveCN110566034BImprove antibacterial propertiesGood flexibilityStain/soil resistant fibresMechanical cleaningPolymer scienceCotton fibre

Owner:安徽嘉明新材料科技有限公司

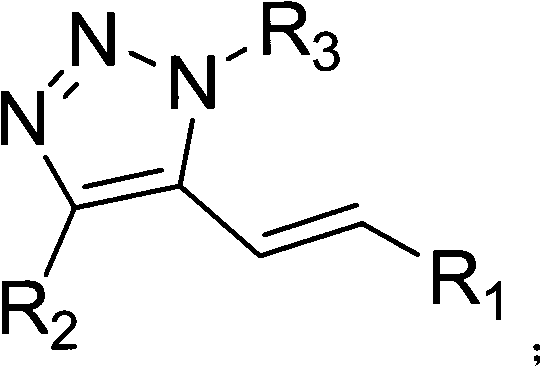

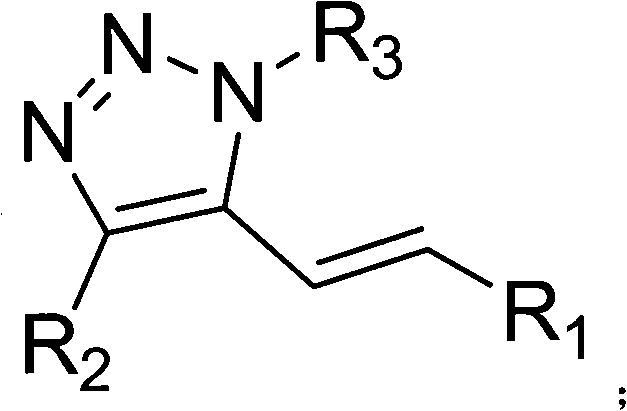

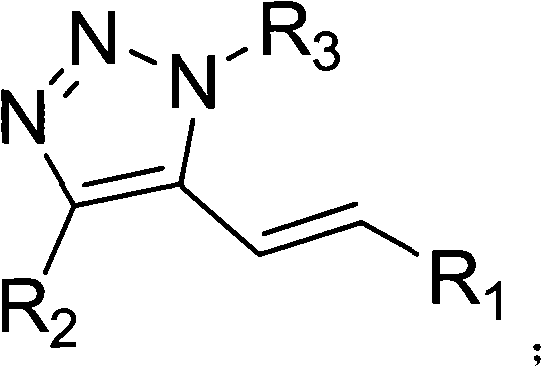

5-alkenyl-1, 4-disubstituted-1, 2, 3-triazole compound, preparation method and application thereof

InactiveCN101704793AReduce pollutionGood reaction selectivityBiocideOrganic chemistry1,2,3-TriazoleStructural formula

The invention discloses a 5-alkenyl-1, 4-disubstituted-1, 2, 3-triazole compound, a preparation method and application thereof. The 5-alkenyl-1, 4-disubstituted-1, 2, 3-triazole compound has the structural formula as follows, R1 is -COOMe, phenyl, p-fluorophenyl or p-methylphenyl; R2 is phenyl, n-hexyl or p-methylphenyl; and R 3 is phenyl, phenmethyl, n-butyl or n-octyl. The preparation method has good reaction selectivity, simple and feasible steps, low price of the raw materials used in the reaction and easily obtained raw materials, and is beneficial to industrialized production; furthermore, the compound can be used for preparing pesticide or bactericide of fruit trees, melons, beans, solanaceous fruits, flowers and the like, has good desinsection and sterilizing effects and is beneficial to environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com