Glue-filling waterproof photovoltaic junction box

A volt junction box and glue filling technology, which is applied in the field of junction boxes, can solve problems such as aging of waterproof components, unimaginable consequences, and increased glue filling volume, achieving strong waterproof and dustproof capabilities, reducing processing procedures, and reducing glue filling volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

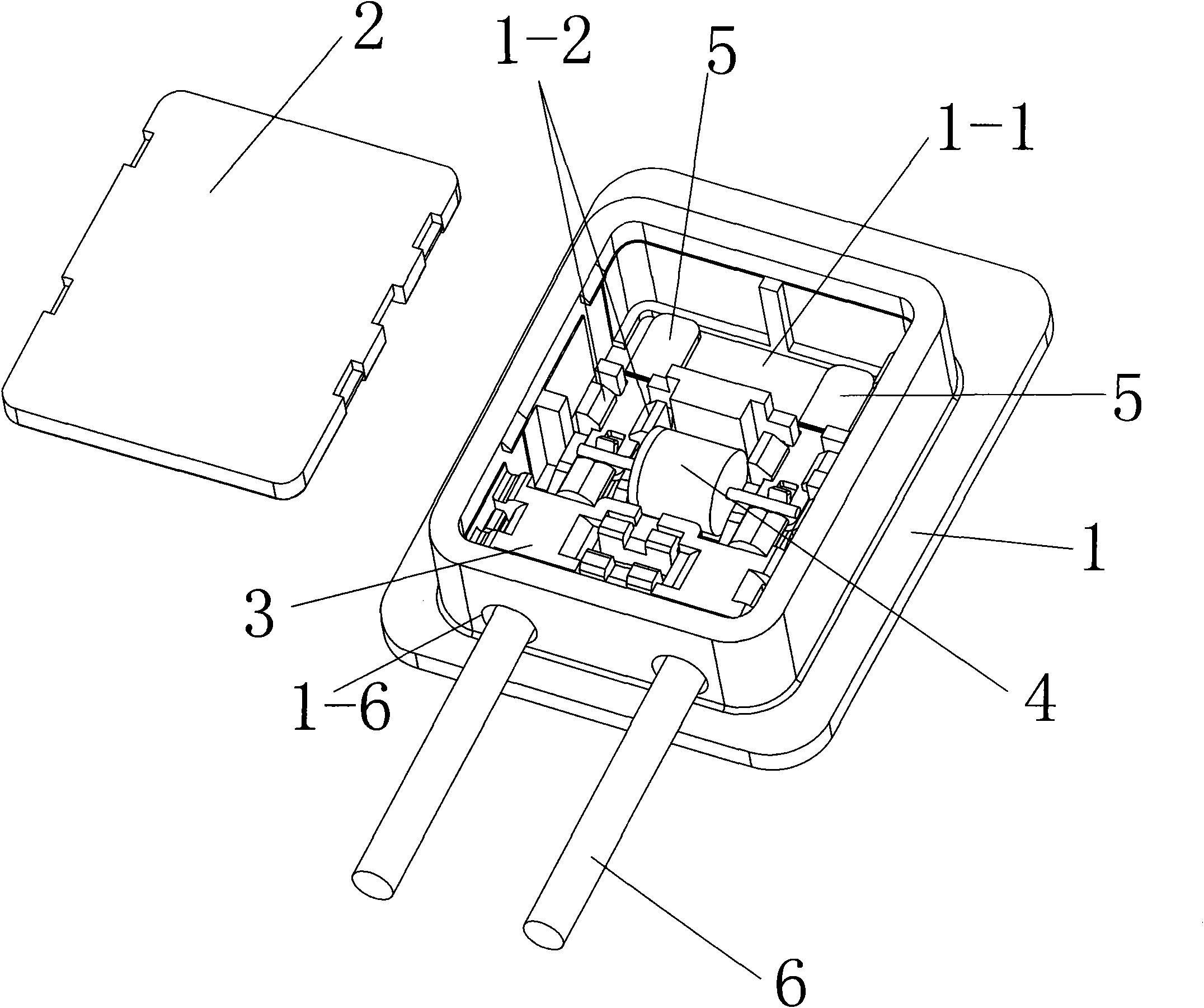

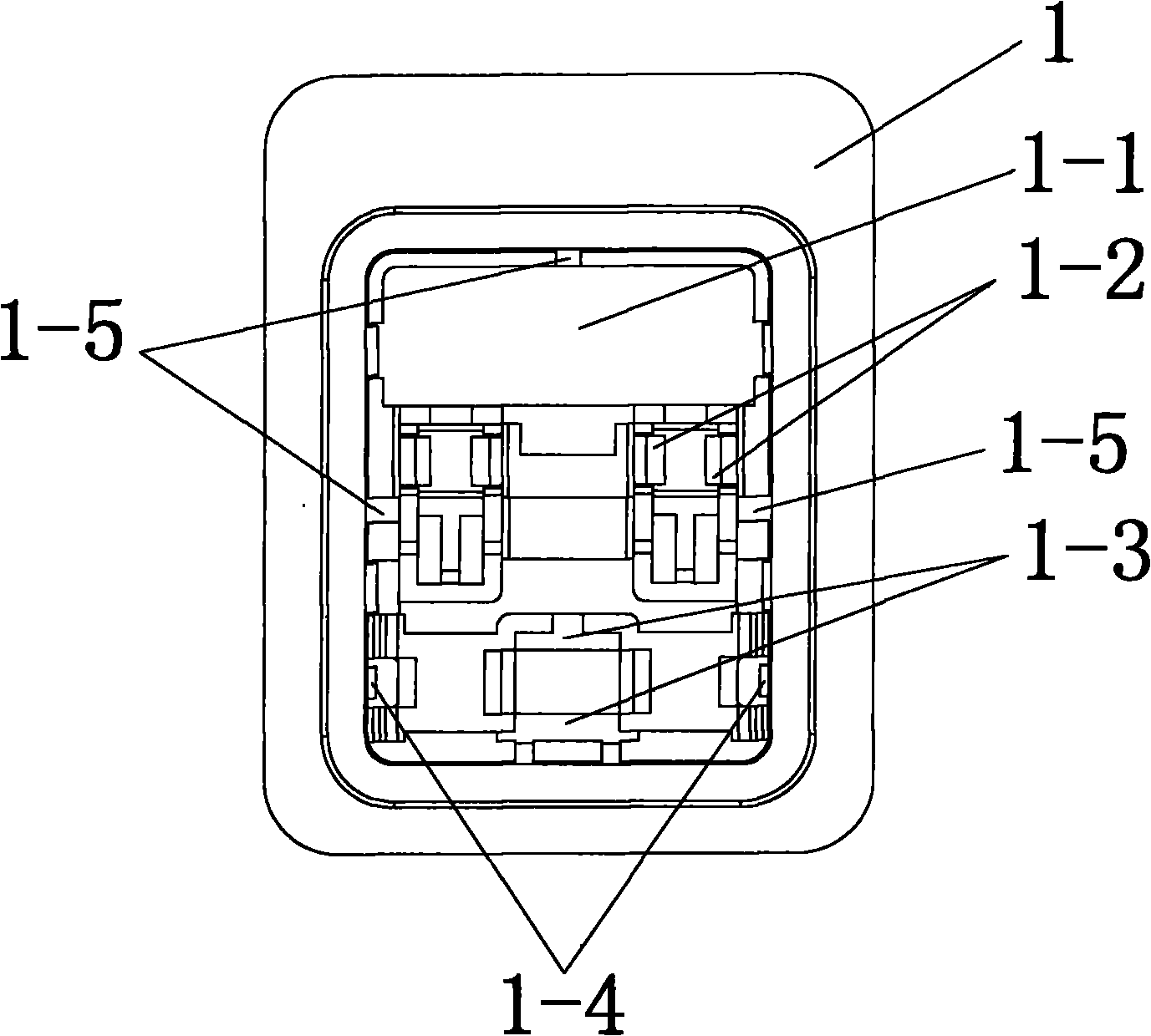

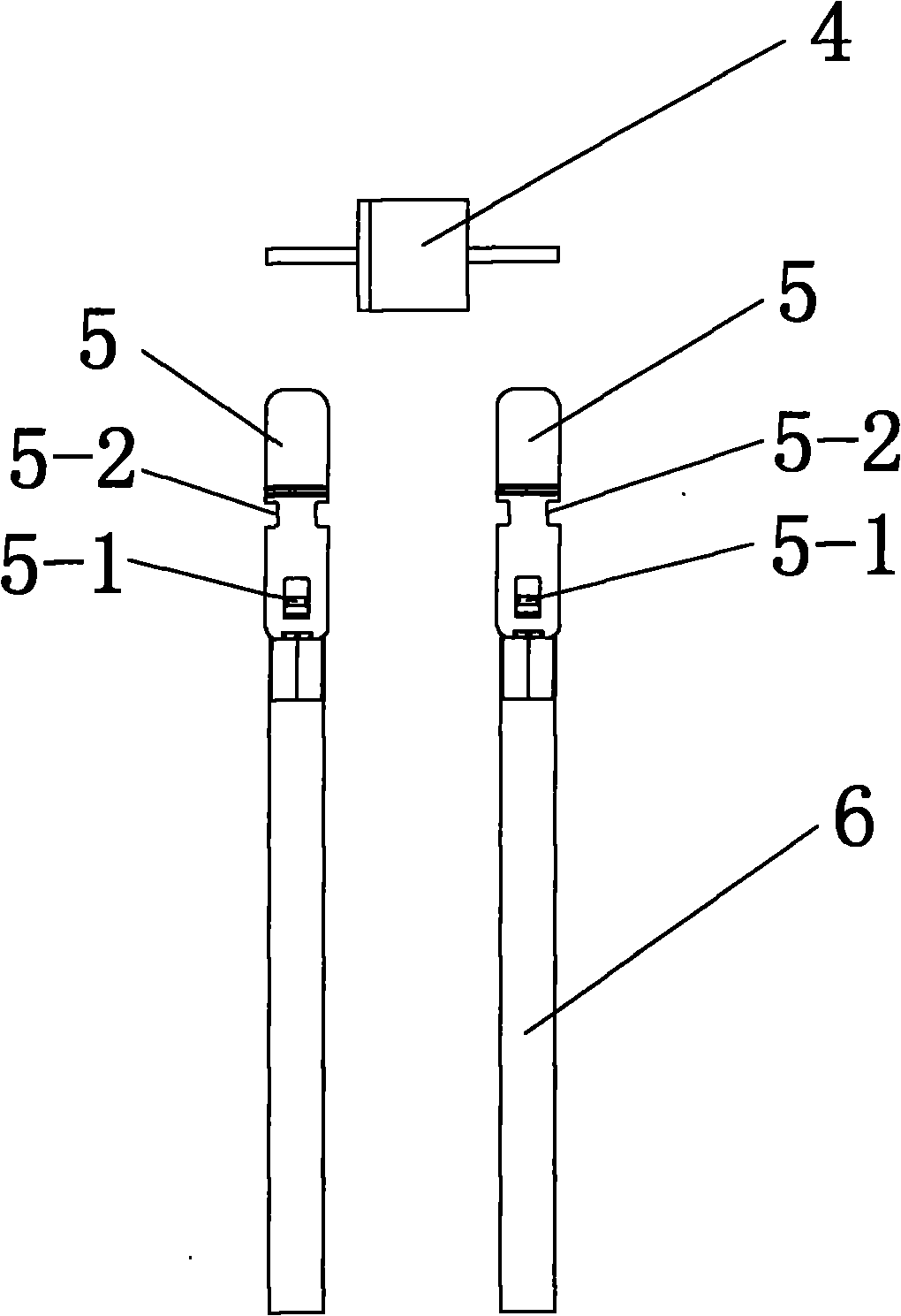

[0021] combine Figure 1~4 A glue-filled waterproof photovoltaic junction box is shown, which is provided with a box body 1 and a box cover 2 with a cavity 1-1, and a wiring cable channel for placing cables 6 is opened on one side of the box body 1. Hole 1-6, the middle part of the cavity 1-1 is provided with two clamping modules 1-2, and the two sides of the bottom are provided with buckles 1-4, and the inside of the two clamping modules 1-2 Each clamping connection has a metal terminal 5. In order to make the connection between the metal terminal and the clamping module stronger, an inner groove 5-2 can be provided at the contact position between the metal terminal 5 and the clamping module 1-2. There is a diode 4 welded on the metal terminal 5, and the two ends of the diode 4 can be installed in the diode welding groove 5-1 of the metal terminal 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com