Polyolefin hot melt glue composition for woodworking precoating and edge sealing and preparation method thereof

A technology of polyolefin and hot-melt adhesives, applied in the field of polyolefin hot-melt adhesives, which can solve the problems of large amount of glue used, limited use, poor weather resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

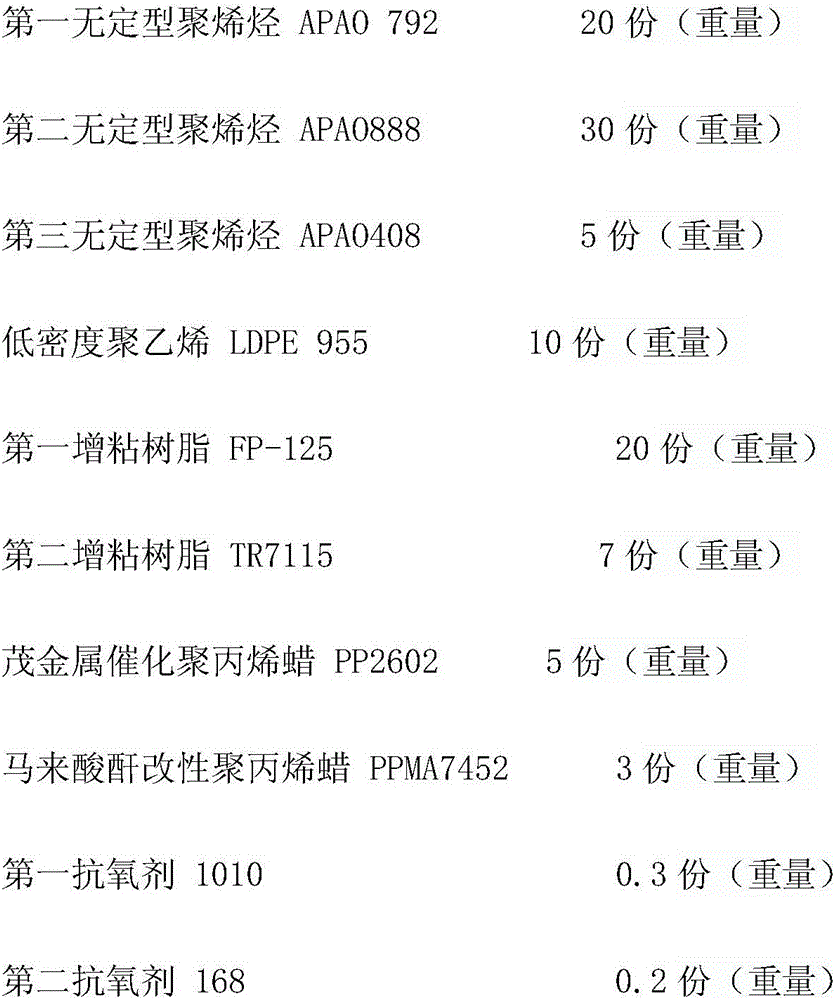

Embodiment 1

[0018] The preparation method is as follows:

[0019] Put metallocene catalyzed polypropylene wax PP2602, maleic anhydride modified polypropylene wax PPMA7452 tackifying resin FP-125, TR7115, first antioxidant 1010, and first antioxidant 168 into an electric heating reaction furnace for heating and heating The temperature is controlled at 180°C, and the stirring is started. After it is completely melted, add the first amorphous polyolefin APAO792, the second amorphous polyolefin APAO888, the third amorphous polyolefin APAO408 and low-density polyethylene LDPE 955. After stirring for 30 minutes, Turn on the vacuum, the vacuum pressure is less than -0.9MPa, and continue to stir for 60 minutes to ensure that the material is melted evenly.

[0020]

[0021] The amorphous polyolefin is an ethylene-propylene copolymer, and the comprehensive preferred proportion of APAO 792, APAO888, and APAO 408 is 45-55 parts (by weight) based on the characteristics of softening point, material ...

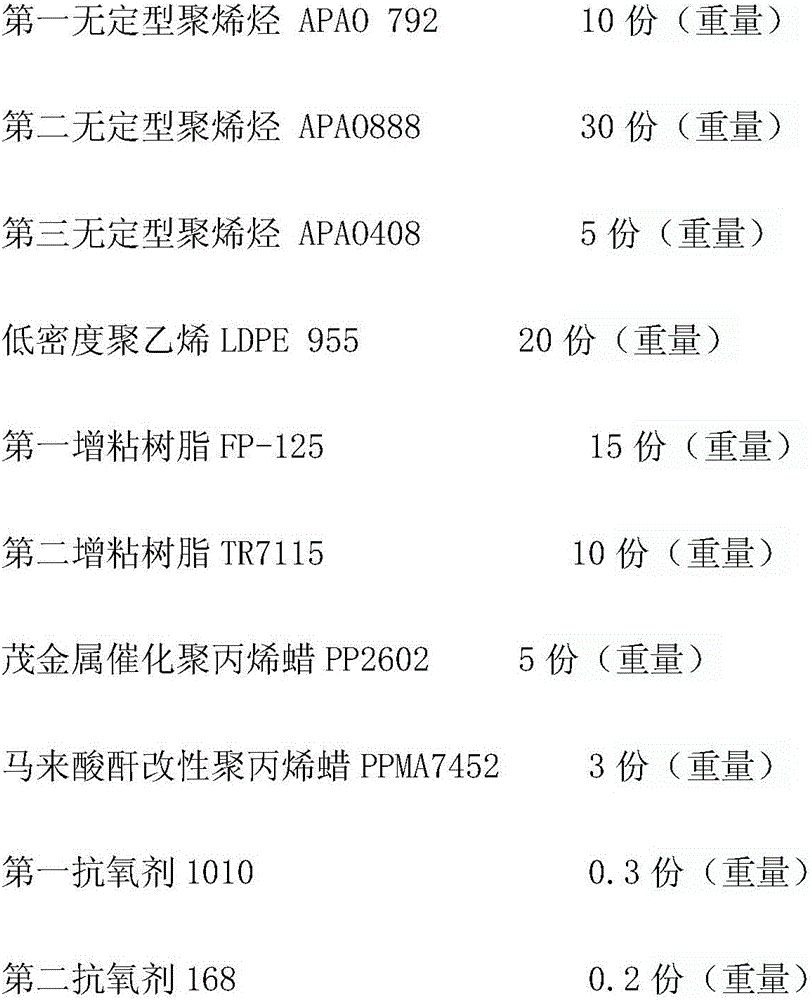

Embodiment 2

[0026] The preparation method is as follows:

[0027] Put metallocene catalyzed polypropylene wax PP2602, maleic anhydride modified polypropylene wax PPMA7452 tackifying resin FP-125, TR7115, first antioxidant 1010, and first antioxidant 168 into an electric heating reaction furnace for heating and heating The temperature is controlled at 180°C, and the stirring is started. After it is completely melted, add the first amorphous polyolefin APAO792, the second amorphous polyolefin APAO888, the third amorphous polyolefin APAO408 and low-density polyethylene LDPE 955. After stirring for 20 minutes, Turn on the vacuum, the vacuum pressure is less than -0.9MPa, and continue to stir for 90 minutes to ensure that the material is melted evenly.

[0028]

[0029] Amorphous polyolefin is an ethylene-propylene copolymer, which is optimized for comprehensive softening point, material strength, hardness, etc.

[0030] The comprehensive preferred ratio of APAO 792, APAO888, and APAO 408 ...

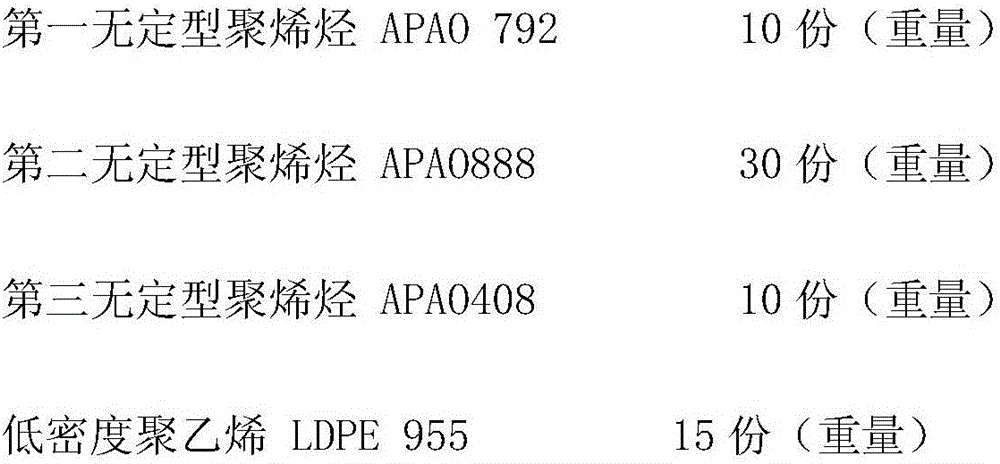

Embodiment 3

[0035] The preparation method is as follows:

[0036] Put metallocene catalyzed polypropylene wax PP2602, maleic anhydride modified polypropylene wax PPMA7452 tackifying resin FP-125, TR7115, first antioxidant 1010, and first antioxidant 168 into an electric heating reaction furnace for heating and heating The temperature is controlled at 190°C, and the stirring is started. After it is completely melted, the first amorphous polyolefin APAO792, the second amorphous polyolefin APAO888, the third amorphous polyolefin APAO408 and low-density polyethylene LDPE 955 are added, and after stirring for 40 minutes, Turn on the vacuum, the vacuum pressure is less than -0.9MPa, and continue to stir for 90 minutes to ensure that the material is melted evenly.

[0037]

[0038]

[0039] Amorphous polyolefin is an ethylene-propylene copolymer, which is optimized for comprehensive softening point, material strength, hardness, etc.

[0040] The comprehensive preferred ratio of APAO 792, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com