Unidirectional fabric, non-woven fabric, preparation methods of fabrics and non-woven fabric product

A technology of unidirectional fabrics and weft-free fabrics, which is applied in the field of unidirectional fabrics, weft-free fabrics and their preparation, and unidirectional fabrics, and can solve the problem of reducing the strength of unidirectional fabrics or weft-free fabrics, bulletproof performance, and hindering unidirectional fabrics. Problems such as energy transmission of cloth or no weft cloth, complex warping process, etc., to improve the protective performance such as bulletproof, reduce the probability of damage, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

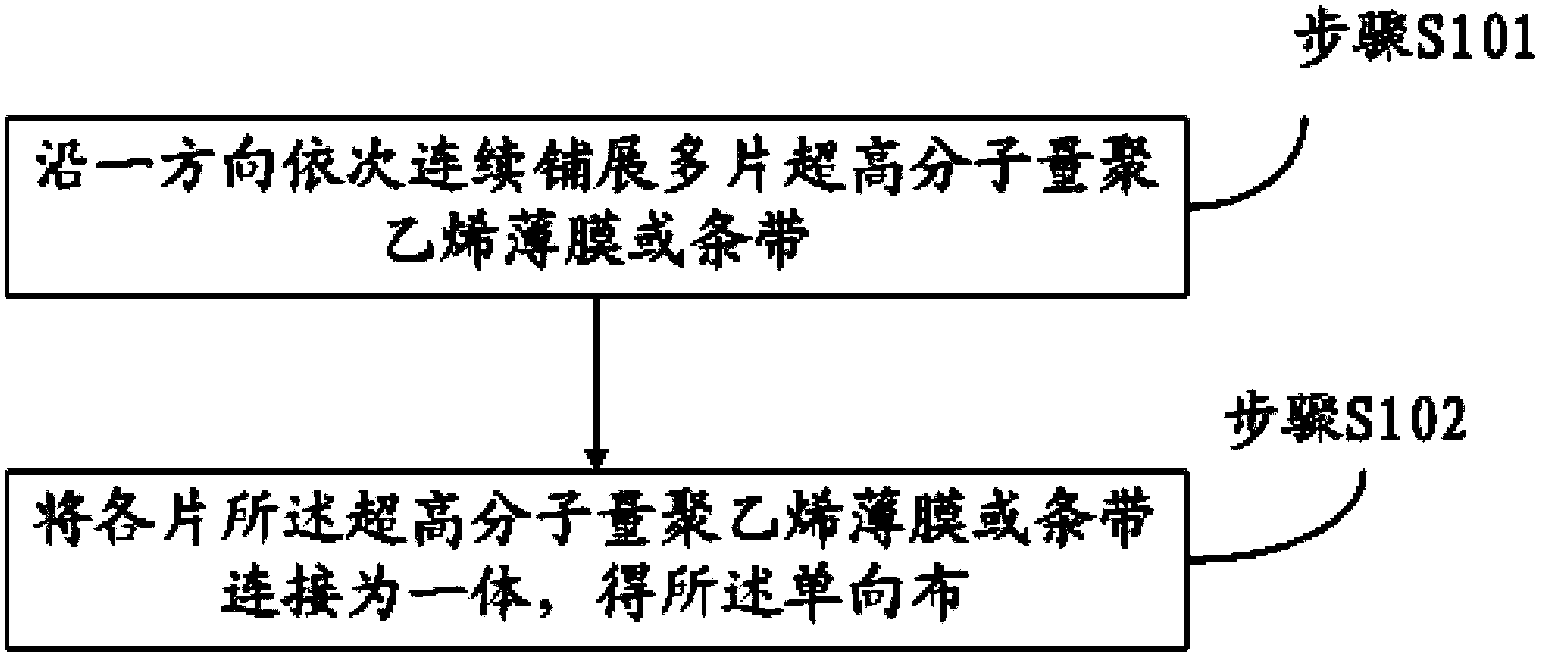

[0063] Such as figure 1 As shown, a kind of unidirectional cloth preparation method provided in this embodiment comprises:

[0064] Step S101, continuously spreading multiple ultra-high molecular weight polyethylene films or strips sequentially along one direction;

[0065] Step S102, connecting each piece of the ultra-high molecular weight polyethylene film or strip into one to obtain the unidirectional fabric.

[0066] The core idea of this embodiment is to use ultra-high molecular weight polyethylene films or strips to directly replace traditional ultra-high molecular weight polyethylene fibers to prepare unidirectional fabrics.

[0067] A plurality of ultra-high molecular weight polyethylene films or strips are continuously spread sequentially along the width direction of the ultra-high molecular weight polyethylene film or strip, and the width direction is perpendicular to the molecular chain stretching direction of the ultra-high molecular weight polyethylene film or ...

Embodiment 2

[0084] The unidirectional fabric provided in this embodiment includes: a plurality of ultra-high molecular weight polyethylene films or strips that are successively spread in one direction and connected to each other.

[0085] In this embodiment, the ultra-high molecular weight polyethylene film is a thin sheet made of ultra-high molecular weight polyethylene with a certain width and thickness, and the width is much larger than the thickness. The strips are divided by stretching the film. The strip-shaped flakes formed by the cutting process have a width smaller than that of the film and a thickness equivalent to that of the film. Ultra-high molecular weight polyethylene film or strip itself has a certain width and thickness. It is an integral structure without joint points or cutting lines. It has high strength, large modulus, and low creep. The influence range of stress concentration and so on.

[0086] Optionally, the direction is the width direction of the ultra-high mole...

Embodiment 3

[0095] Such as Figure 5 As shown, the present embodiment provides a method for preparing a weft-free fabric comprising:

[0096] Step S201, multiple unidirectional fabrics are sequentially cross-composited at a certain angle;

[0097] Step S202, laminating multiple pieces of cross-composited unidirectional fabrics into one to obtain the non-weft fabric.

[0098] The unidirectional fabric includes: multiple ultra-high molecular weight polyethylene films or strips that are continuously spread in one direction and connected to each other.

[0099] Optionally, multiple pieces of unidirectional fabrics are sequentially cross-laminated at a certain angle, including:

[0100] Multiple pieces of unidirectional fabrics are sequentially laid and laid crosswise at a certain angle, and the overlapped parts of the multiple pieces of unidirectional fabrics are hot-pressed or glued.

[0101] If the method of gluing is adopted, glue is applied to one side of the unidirectional cloth and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com