Glass plate with adhesive and interlaid metallic net

A metal mesh and glass plate technology, which is applied in the field of metal mesh glass plate, can solve the problems that the application and promotion are not widely accepted, reduce the impact strength of the metal wire, and achieve easy aesthetics, easy cleaning, and not easy to break. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

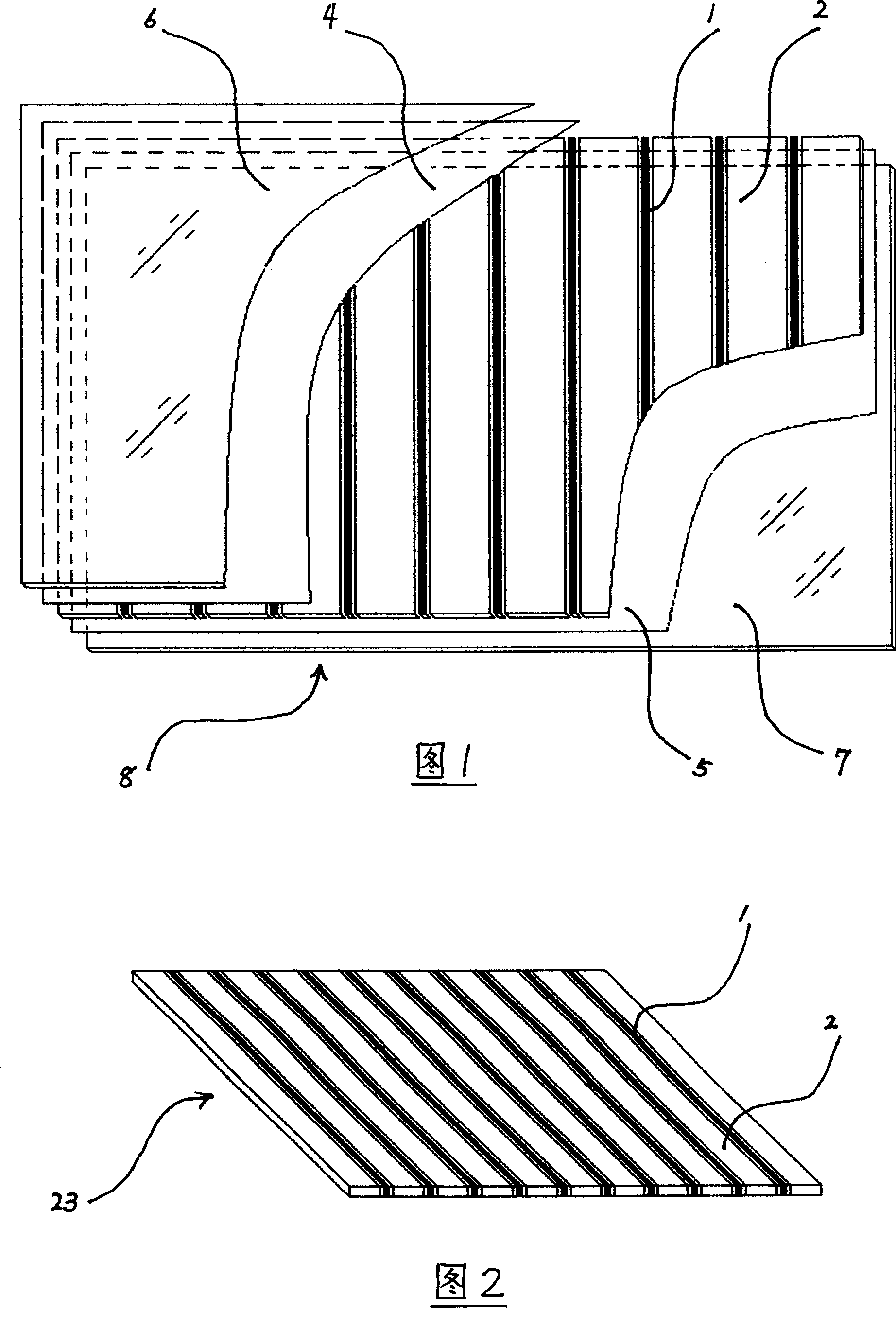

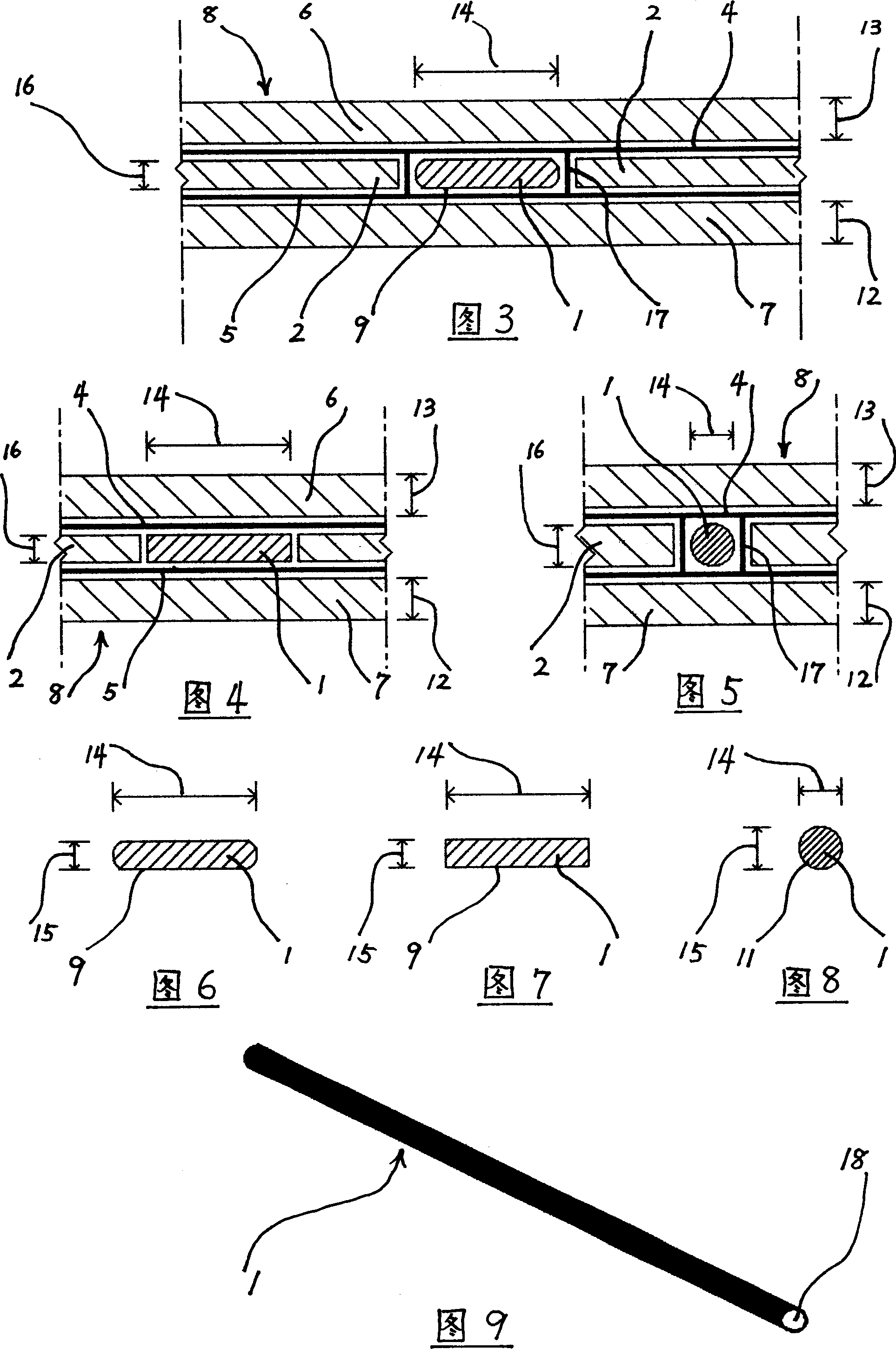

[0057] Embodiment 1, Fig. 1 is a schematic diagram of an exploded structure of a preferred implementation example of a laminated metal mesh glass plate according to the present invention. In order to see clearly, the upper part has been removed layer by layer from the lower right corner of the figure, so that Part of the structure below is exposed. The laminated metal mesh glass plate is 980mm wide and 700mm high, and the thickness of the glass plates is about 8.5mm when they are stacked together. As shown in Figure 1, the laminated metal mesh glass plate 8 has a five-layer laminated structure, including a top layer of a whole piece of transparent silicate glass plate 6 and a bottom layer of a piece of transparent silicate glass plate 7, which are respectively float The size of the soda-lime silicate flat glass produced is 980mm×700mm×3mm; next to the inside is the upper transparent film 4 and the lower transparent film 5, which are made by wet process of WSJ-655 acrylic acid ...

Embodiment 2

[0064] Embodiment 2 is an example of a laminated glass plate embedded with metal mesh according to the present invention using a dry method. On a push-pull plastic-steel window installed on a 1500mm×1500mm window in a building, the plastic-steel window has two of the same size and can Each of the freely sliding window sashes is independently installed with a laminated glass plate embedded with metal mesh according to the present invention. The size of the laminated glass plate 8 embedded with metal mesh in one of the fans is as follows: the glass plate is 1335mm high, 660mm wide, and about 8.7mm thick. Plate 7, they are all soda-lime-silicon flat glass produced by float method, and the size is 1335mm × 660mm × 3mm; next inward is the upper layer of transparent film 4 and the lower layer of transparent film 5, which adopts PVB film through dry process The thickness is 0.38mm respectively; finally sandwiched in the middle is seven pieces of 650mm×118mm×2mm transparent silicate p...

Embodiment 3

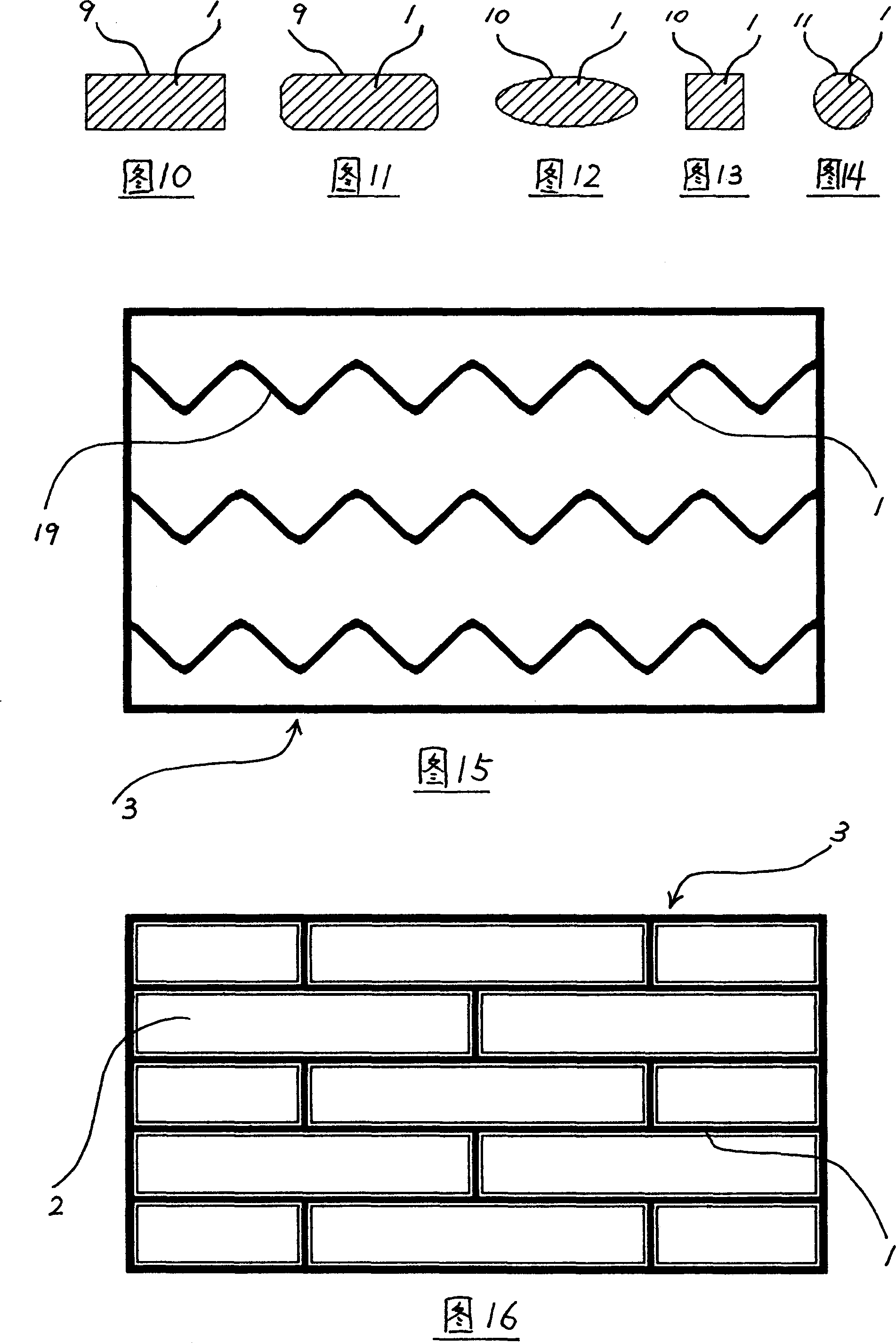

[0067] Embodiment 3 is another implementation example of a laminated metal mesh glass plate of the present invention manufactured by a wet method. The metal mesh in the laminated metal mesh glass plate 8 is a flat mesh connection structure, and the thickness of the metal mesh is Equal to the thickness of the metal strips constituting the metal mesh, the metal strip 1 is a round steel strip with a diameter of 3mm and bent into a wave pattern 19, and the metal strips are directly connected to each other by welding to form the pattern of the metal mesh 3 as shown in Figure 15. The metal mesh is 970mm wide, 560mm high, and 3mm thick. The center distance between the three steel bars bent into a wave pattern is 180mm, but the vertical distance between the two groups of relative wave peaks is only 100mm, and the shortest distance between the wave peaks is only 100mm. It is 130mm, which can be regarded as the minimum inner diameter of the mesh; in the two mesh holes on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com