Assembled steel tube high-strength concrete columns and construction method thereof

A high-strength concrete and prefabricated technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of concrete and steel pipes that are prone to cracks and gaps, prone to corrosion, and poor fire performance, so as to save manual work and ensure fire resistance. Torsional and shear resistance, fire resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

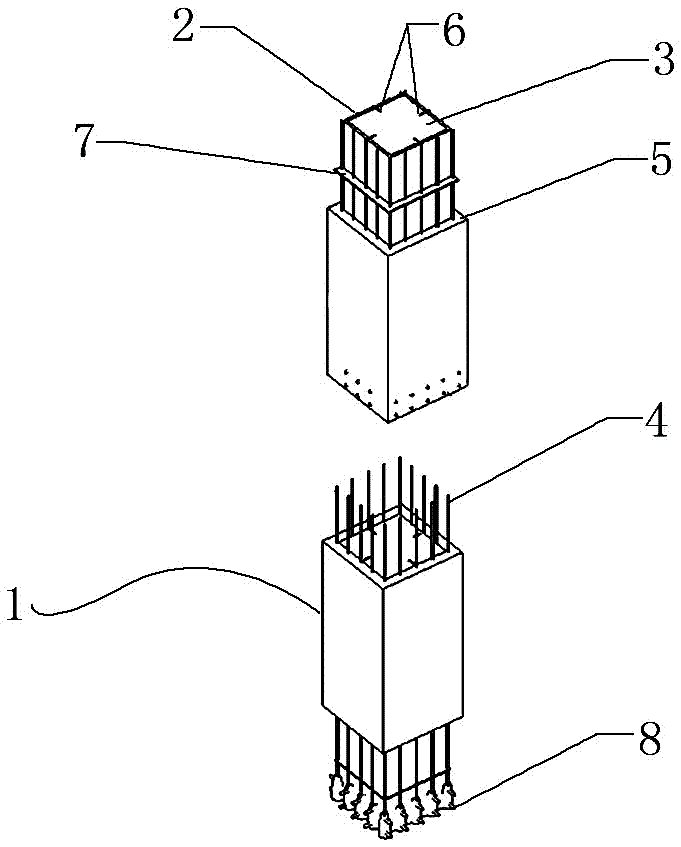

[0038] Such as figure 1 As shown, the prefabricated steel pipe high-strength concrete column of the present invention is formed by sequentially connecting prefabricated standard column sections 1. The standard column section 1 includes steel pipes 2, high-strength concrete 3 poured in the steel pipes 2, and stiffeners around the outside of the steel pipes 2. Rib 4 and ordinary concrete 5 poured outside the steel pipe 2.

[0039] The cross-sectional shape of the steel pipe 2 is circular or square according to the design requirements. The inner wall of the steel pipe 2 is welded and fixed with vertical rib groups. distribution, each vertical rib group includes a number of vertical ribs 6, arranged at uniform intervals along the length direction of the steel pipe 2, the vertical ribs 6 are made of rectangular steel plates with a thickness of 2mm, and the longer sides of the vertical ribs 6 Welded with the inner wall of the steel pipe 2; when the steel pipe 2 is a circular pipe, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com